- 07

- Jun

What specialty does circuit board belong to?

Mobile phone circuit design belongs to the specialty of electronic circuit design and technology.

Graduates majoring in electronic circuit design and technology can be engaged in product design and production preparation of electronic circuits, precision graphic manufacturing, numerical control processing, process control of circuit manufacturing, testing of circuit manufacturing, quality control and control of circuit manufacturing in electronic factories or research institutes. They can also be engaged in the procurement and sales of electronic circuits and raw and auxiliary materials, chip component assembly, etc.

In the application of power electronics technology and various power systems, switching power supply technology is at the core. For large-scale electrolytic electroplating power supply, the traditional circuit is very large and cumbersome. If Galton switching power supply technology is adopted, its volume and weight will be greatly reduced, and the power utilization efficiency will be greatly improved, materials will be saved, and the cost will be reduced. In electric vehicles and variable frequency drives, switching power supply technology is indispensable. Switching power supply can change the power frequency, so as to achieve nearly ideal load matching and drive control. High frequency switching power supply technology is the core technology of various high-power switching power supplies (inverter welding machine, communication power supply, high-frequency heating power supply, laser power supply, power operation power supply, etc.).

What industry does Производство на печатни платки принадлежи на

PCB manufacturing is a modern electronic industry.

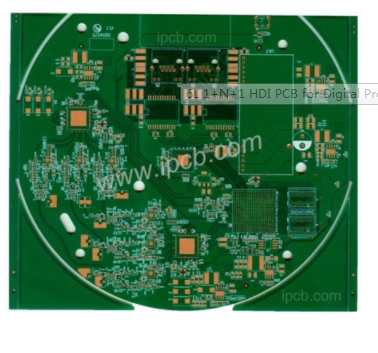

Circuit board is also known as PCB, aluminum substrate, high frequency board, печатна платка, flexible board, etc.

The raw material of the circuit board is glass fiber, which can be seen from our daily life. For example, the core of fire-proof cloth and fire-proof felt is glass fiber. Glass fiber is easy to be combined with resin. We immerse the glass fiber cloth with compact structure and high strength into the resin and harden it to obtain a PCB substrate that is insulated and not easy to bend — if the PCB board is broken, the edges are white and layered, which is enough to prove that the material is resin glass fiber.

Three trends of future development of PCB industry

1. The demand of electric vehicles for PCB increased significantly. Under the electric and intelligent dual wheel drive, the automotive electronics market has expanded rapidly, maintaining an annual growth rate of more than 15% in recent years. Accordingly, the PCB market for motor cars has continued to rise.

2. The demand of 5g communication industry is approaching. China’s 5g construction investment will reach 705billion yuan, an increase of 56.7% over 4G investment. Compared with 2g-4g communication system, 5g will make more use of 3000-5000mhz and millimeter wave frequency band, and require the data transmission rate to be increased by more than 10 times. The construction of ultra dense small base stations brought about by 5g commerce will bring a lot of high-frequency PCB demand.

3. Smart phones have increased demand for FPC. FPC is thin and flexible. FPC applications include antenna, camera, display module, touch module, etc. At present, Apple’s annual purchase of FPC accounts for about half of the global market share. Each iPhone uses about 14-16 FPCs, and the single ASP is nearly $30.

Ipcb is a manufacturer with many years of PCB production experience. It has the PCB manufacturing capacity of 1-40 layers, such as hard board, soft board, soft hard combination board, HDI and metal substrate. Its products are widely used in industrial control, security, consumption, power supply, automotive electronics and other fields. Hope that people from all walks of life who need inquiry and joint development.