- 11

- Jun

Ramin jagora (via) Gabatarwa

Kwamitin kewayawa ya ƙunshi yadudduka na da’irori na tagulla, kuma haɗin kai tsakanin yadudduka daban-daban ya dogara da via. Wannan shi ne saboda a zamanin yau, ana yin allon da’ira ta hanyar tono ramuka don haɗawa da nau’ikan da’irar daban-daban. Dalilin haɗin yanar gizon shine don gudanar da wutar lantarki, don haka ana kiran shi via. Domin gudanar da wutar lantarki, dole ne a sanya wani Layer na kayan aiki (yawanci tagulla) a saman ramukan hakowa, ta wannan hanyar, electrons za su iya motsawa tsakanin nau’ikan foil na tagulla daban-daban, saboda kawai guduro a saman farkon rawar sojan. rami ba zai gudanar da wutar lantarki ba.

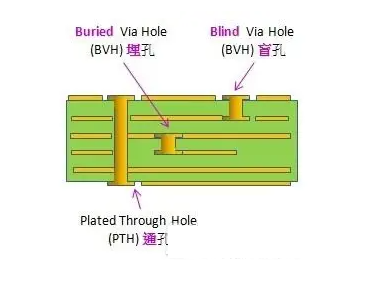

Gabaɗaya, sau da yawa muna ganin iri uku PCB ramukan jagora (via), waɗanda aka bayyana kamar haka:

Ta rami: plating ta rami (PTH a takaice)

Wannan shine mafi yawan nau’in ta hanyar rami. Muddin ka riƙe PCB sama da haske, za ka iya ganin cewa ramin mai haske yana “ta rami”. Wannan kuma shine nau’in rami mafi sauƙi, saboda lokacin yin, kawai wajibi ne a yi amfani da rawar soja ko hasken laser don haƙa dukkan allon da’ira kai tsaye, kuma farashin yana da arha. Ko da yake ramin yana da arha, wani lokacin yana amfani da ƙarin sarari na PCB.

Makafi ta hanyar rami (BVH)

Wurin waje na PCB yana haɗe tare da madaidaicin Layer na ciki ta ramukan lantarki, waɗanda ake kira “ramukan makafi” saboda ba a iya ganin kishiyar. Domin ƙara yawan amfani da sararin samaniya na layin da’irar PCB, an ɓullo da tsarin “ramin makafi”. Wannan hanyar masana’anta yana buƙatar kulawa ta musamman ga zurfin zurfin rami mai zurfi (Z-axis). Za’a iya haƙa sassan da’irar da ake buƙatar haɗawa a cikin nau’ikan da’irar guda ɗaya a gaba, sannan a haɗa su. Koyaya, ana buƙatar ƙarin madaidaicin matsayi da na’urar daidaitawa.

An binne ta ta rami (BVH)

Ana haɗa kowane Layer da ke cikin PCB amma ba a haɗa shi da Layer na waje ba. Ba za a iya samun wannan tsari ta hanyar amfani da hanyar hakowa bayan haɗin gwiwa. Dole ne a yi hakowa a lokacin nau’ikan da’irar ɗaya ɗaya. Bayan haɗin gida na Layer na ciki, dole ne a aiwatar da electroplating kafin duk haɗin gwiwa. Yana ɗaukar lokaci fiye da ainihin “ta hanyar ramuka” da “ramukan makafi”, don haka farashin kuma ya fi tsada. Ana amfani da wannan tsari ne kawai don babban yawa (HDI) Bugun Circuit Batun don ƙara sararin da ake amfani da shi na sauran yadudduka kewaye.