- 25

- Mar

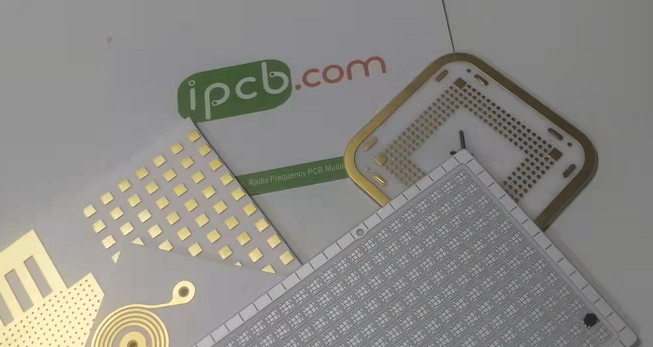

Alumina Ceramic PCB

Dab tsi yog cov kev siv tshwj xeeb ntawm alumina ceramic substrate

Hauv PCB pov thawj, alumina ceramic substrate tau dav siv hauv ntau qhov kev lag luam. Txawm li cas los xij, hauv cov ntawv thov tshwj xeeb, cov tuab thiab cov ntsiab lus ntawm txhua qhov alumina ceramic substrate sib txawv. Qhov no yog vim li cas?

1. Lub thickness ntawm alumina ceramic substrate yog txiav txim siab raws li kev ua haujlwm ntawm cov khoom

Lub thicker lub thickness ntawm alumina ceramic substrate, qhov zoo dua lub zog thiab lub zog ntawm lub siab tsis kam, tab sis lub thermal conductivity yog phem tshaj qhov nyias nyias; Ntawm qhov tsis sib xws, qhov nyias nyias ntawm alumina ceramic substrate, lub zog thiab siab ua haujlwm tsis zoo li cov tuab, tab sis cov thermal conductivity muaj zog dua cov tuab. Lub thickness ntawm alumina ceramic substrate feem ntau yog 0.254mm, 0.385mm thiab 1.0mm / 2.0mm / 3.0mm / 4.0mm, thiab lwm yam.

2. Cov specifications thiab qhov ntau thiab tsawg ntawm alumina ceramic substrates kuj txawv

Feem ntau, alumina ceramic substrate yog me dua li PCB board tag nrho, thiab nws qhov loj yog feem ntau tsis ntau tshaj 120mmx120mm. Cov tshaj qhov loj no feem ntau yuav tsum tau kho. Tsis tas li ntawd, qhov loj ntawm alumina ceramic substrate tsis yog qhov loj dua qhov zoo dua, feem ntau vim nws cov substrate yog ua los ntawm ceramics. Nyob rau hauv cov txheej txheem ntawm PCB pov thawj, nws yog ib qho yooj yim uas yuav ua rau cov phaj fragmentation, uas ua rau ntau cov khib nyiab.

3. Cov duab ntawm alumina ceramic substrate yog txawv

Alumina ceramic substrates feem ntau yog ib leeg thiab ob sab phaj, nrog cov duab plaub, square thiab voj voog. Hauv kev pov thawj PCB, raws li cov txheej txheem yuav tsum tau ua, qee qhov kuj yuav tsum tau ua grooves ntawm ceramic substrate thiab pas dej ua ke txheej txheem.

Cov yam ntxwv ntawm alumina ceramic substrate muaj xws li:

1. Muaj kev ntxhov siab thiab ruaj khov; Siab zog, siab thermal conductivity thiab rwb thaiv tsev siab; Muaj zog adhesion thiab anti-corrosion.

2. Zoo thermal voj voog kev ua haujlwm, nrog 50000 lub voj voog thiab kev ntseeg siab.

3. Zoo li PCB pawg thawj coj saib (lossis IMS substrate), nws tuaj yeem etch cov qauv ntawm ntau yam duab; Tsis muaj kuab paug thiab muaj kuab paug.

4. Kev ua haujlwm kub ntau: – 55 ℃ ~ 850 ℃; Lub coefficient ntawm thermal expansion yog ze rau silicon, uas yooj yim rau kev tsim cov txheej txheem ntawm lub zog module.

Dab tsi yog qhov zoo ntawm alumina ceramic substrate?

A. Lub thermal expansion coefficient ntawm ceramic substrate yog ze rau ntawm silicon nti, uas tuaj yeem txuag cov txheej txheem Mo nti, txuag zog, cov ntaub ntawv thiab txo nqi;

B. Vuam txheej, txo cov thermal tsis kam, txo cov kab noj hniav thiab txhim kho cov txiaj ntsig;

C. Cov kab dav ntawm 0.3mm tuab tooj liab ntawv ci tsuas yog 10% ntawm cov ntawv luam tawm zoo tib yam;

D. Lub thermal conductivity ntawm cov nti ua rau lub pob ntawm cov nti compact heev, uas zoo heev txhim kho lub zog ceev thiab txhim kho kev ntseeg siab ntawm lub system thiab ntaus ntawv;

E. Hom (0.25mm) ceramic substrate tuaj yeem hloov BeO yam tsis muaj toxicity;

F. Loj, 100A tam sim no tsis tu ncua hla 1 hli dav thiab 0.3 hli tuab tooj liab lub cev, thiab qhov kub thiab txias yog li 17 ℃; 100A tam sim no tsis tu ncua hla 2 hli dav thiab 0.3 hli tuab tooj liab lub cev, thiab qhov kub nce tsuas yog li 5 ℃;

G. Tsawg, 10 × Lub thermal kuj ntawm 10 hli ceramic substrate, 0.63mm tuab ceramic substrate, 0.31k / w, 0.38mm tuab ceramic substrate thiab 0.14k / w feem;

H. Kev kub siab tsis kam, ua kom muaj kev nyab xeeb ntawm tus kheej thiab cov cuab yeej tiv thaiv muaj peev xwm;

1. Paub txog cov txheej txheem ntim khoom tshiab thiab kev sib dhos, kom cov khoom sib xyaw ua ke thiab qhov ntim tau txo.