- 12

- May

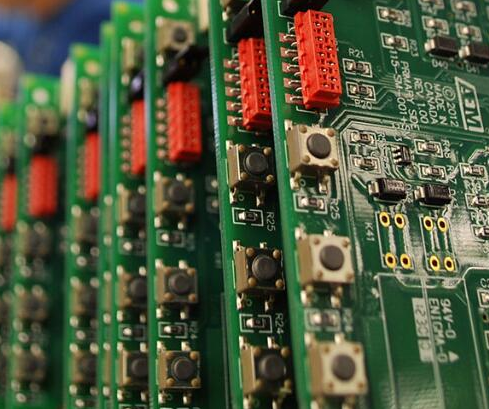

Qhov yuav tsum tau ua rau PCBA vuam txheej txheem

PCBA welding processing feem ntau muaj ntau qhov yuav tsum tau ua rau PCB pawg thawj coj saib, uas yuav tsum ua kom tau raws li qhov xav tau ntawm vuam. Yog li vim li cas cov txheej txheem vuam xav tau ntau yam kev xav tau rau cov khoom siv hluav taws xob? Qhov tseeb tau ua pov thawj tias yuav muaj ntau yam txheej txheem tshwj xeeb hauv cov txheej txheem ntawm PCBA vuam, thiab daim ntawv thov ntawm cov txheej txheem tshwj xeeb yuav coj cov kev cai rau PCB.

Yog tias lub rooj tsavxwm PCB muaj teeb meem, nws yuav ua rau muaj kev nyuaj ntawm PCBA vuam txheej txheem, thiab tej zaum yuav ua rau vuam tsis xws luag, tsis tsim nyog boards, thiab lwm yam. Yog li ntawd, txhawm rau kom ua tiav cov txheej txheem tshwj xeeb thiab pab txhawb PCBA vuam, PCB pawg thawj coj saib. yuav tsum tau ua kom tau raws li qhov yuav tsum tau ua nyob rau hauv cov nqe lus ntawm qhov loj me thiab ncoo deb.

Tom ntej no, kuv yuav qhia txog qhov yuav tsum tau ua ntawm PCBA welding processing ntawm PCB board.

Qhov yuav tsum tau ua ntawm PCBA vuam txheej txheem ntawm PCB board

1. PCB loj

Qhov dav ntawm PCB (nrog rau cov ntug ntawm lub rooj tsav xwm Circuit Court) yuav tsum siab tshaj 50mm thiab tsawg dua 460mm, thiab qhov ntev ntawm PCB (xws li cov ntug ntawm lub rooj tsavxwm Circuit Court) yuav tsum siab tshaj 50mm. Yog tias qhov loj me dhau lawm, nws yuav tsum tau ua rau hauv panels.

2. PCB ntug dav

Phaj ntug dav> 5 hli, phaj qhov sib nrug <8 hli, qhov deb ntawm lub hauv paus phaj thiab phaj ntug> 5 hli.

3. PCB dabtsi yog khoov

Upward dabtsi yog khoov: <1.2mm, downward dabtsi yog khoov: <0.5mm, PCB deformation: siab tshaj deformation qhov siab ÷ kab pheeb ces kaum ntev <0.25.

4. PCB cim taw tes

Kos duab: txheem voj voog, square thiab daim duab peb sab;

Mark loj: 0.8 ~ 1.5mm;

Cov khoom siv cim: kub plating, tin plating, tooj liab thiab platinum;

Mark lub qhov yuav tsum tau ua: qhov saum npoo yog tiaj, du, tsis muaj oxidation thiab av;

Yuav tsum tau nyob ib ncig ntawm lub cim: yuav tsum tsis muaj teeb meem xws li cov roj ntsuab uas pom tseeb txawv ntawm cov xim ntawm lub cim nyob rau hauv 1 hli ib ncig;

Mark txoj hauj lwm: ntau tshaj 3 hli los ntawm ntug ntawm lub phaj, thiab yuav tsum tsis txhob muaj los ntawm lub qhov, xeem point thiab lwm yam cim nyob rau hauv 5 hli.

5. PCB ncoo

Tsis muaj qhov los ntawm qhov ntawm cov ntaub qhwv ntawm SMD cov khoom. Yog hais tias muaj ib tug los ntawm lub qhov, lub solder muab tshuaj txhuam yuav ntws mus rau hauv lub qhov, uas yuav txo tau cov tin nyob rau hauv lub ntaus ntawv, los yog cov tin ntws mus rau sab nraud, uas ua rau lub board nto tsis sib xws thiab tsis muaj peev xwm luam tau cov tshuaj txhuam hniav.

Hauv PCB tsim thiab tsim khoom, nws yog ib qho tsim nyog yuav tsum nkag siab qee qhov kev paub txog PCB vuam txheej txheem txhawm rau ua kom cov khoom tsim nyog rau kev tsim khoom. Ua ntej tshaj plaws, kev nkag siab txog cov kev cai ntawm kev tsim cov nroj tsuag tuaj yeem ua rau cov txheej txheem tsim khoom tom ntej no zoo dua thiab tsis txhob muaj teeb meem tsis tsim nyog.

Cov saum toj no yog ib qho kev qhia txog cov kev cai ntawm PCBA welding processing ntawm PCB boards. Kuv vam tias nws tuaj yeem pab koj thiab xav paub ntau ntxiv txog PCBA cov ntaub ntawv ua haujlwm vuam.