- 13

- Jul

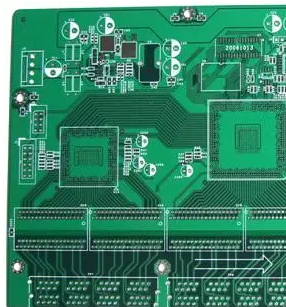

Composition analysis of PCB nickel plating solution

On PCB, nickel is used as the substrate coating of precious and base metals. At the same time, for some single-sided printed boards, nickel is also commonly used as the surface layer. Next, I’ll share with you the components of PCB nickel plating solution

1. Main salt: nickel sulfamate and nickel sulfate are the main salts in nickel solution, which mainly provide nickel metal ions required for nickel plating and also play the role of conductive salt. With high nickel salt content, high cathode current density can be used, and the deposition speed is fast. It is commonly used for high-speed thick nickel plating. Low nickel salt content leads to low deposition rate, but the dispersion ability is very good, and fine and bright crystalline coatings can be obtained.

2. Buffer: boric acid is used as a buffer to maintain the pH value of nickel plating solution within a certain range. Boric acid not only has the function of pH buffer, but also can improve the cathodic polarization, so as to improve the performance of the bath.

3. Anode activator: nickel anode is easy to passivate during power on. In order to ensure the normal dissolution of the anode, a certain amount of anode activator is added to the plating solution

4. Additive: the main component of the additive is stress relief agent. Commonly used additives are naphthalene sulfonic acid, p-toluenesulfonamide, saccharin, etc.

5. Wetting agent: in order to reduce or prevent the generation of pinholes, a small amount of wetting agent should be added to the plating solution, such as sodium dodecyl sulfate, sodium diethylhexyl sulfate, sodium octyl sulfate, etc