- 25

- Mar

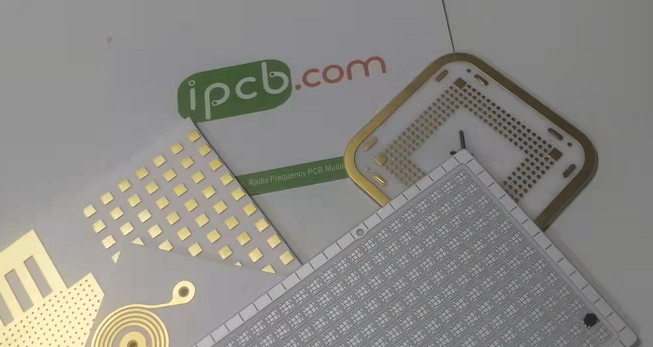

Alumina Ceramic PCB

Kodi ntchito zenizeni za alumina ceramic substrate ndi chiyani

Pakutsimikizira kwa PCB, gawo lapansi la alumina ceramic lagwiritsidwa ntchito kwambiri m’mafakitale ambiri. Komabe, pamagwiritsidwe apadera, makulidwe ndi mawonekedwe a gawo lililonse la alumina ceramic ndizosiyana. Chifukwa chiyani?

1. Makulidwe a alumina ceramic gawo lapansi amatsimikiziridwa molingana ndi ntchito ya mankhwala

Kukhuthala kwa gawo lapansi la alumina ceramic gawo lapansi, kumapangitsanso mphamvu komanso kulimba kwamphamvu, koma kutenthetsa kwamafuta kumakhala koyipa kuposa kuonda; M’malo mwake, kuonda kwa alumina ceramic gawo lapansi, mphamvu ndi kukana kukanikiza sizolimba ngati zokhuthala, koma matenthedwe amatenthedwe ndi amphamvu kuposa wandiweyani. Makulidwe a alumina ceramic gawo lapansi nthawi zambiri ndi 0.254mm, 0.385mm ndi 1.0mm/2.0mm/3.0mm/4.0 Mm, etc.

2. Mafotokozedwe ndi makulidwe a magawo a alumina ceramic nawonso amasiyana

Nthawi zambiri, gawo lapansi la alumina ceramic ndi locheperako kuposa bolodi la PCB wamba lonse, ndipo kukula kwake sikuposa 120mmx120mm. Zoposa kukula uku zimafunikira kusinthidwa mwamakonda. Kuphatikiza apo, kukula kwa gawo lapansi la alumina ceramic sikokulirapo kuposako, makamaka chifukwa gawo lake limapangidwa ndi zoumba. M’kati mwa PCB proofing, n’zosavuta kutsogolera mbale kugawikana, kuchititsa zinyalala zambiri.

3. Maonekedwe a alumina ceramic gawo lapansi ndi osiyana

Magawo a aluminiyamu ceramic nthawi zambiri amakhala amodzi komanso ambali ziwiri, okhala ndi mawonekedwe amakona anayi, masikweya ndi ozungulira. Pakutsimikizira kwa PCB, molingana ndi zofunikira za ndondomekoyi, ena amafunikiranso kupanga ma grooves pa gawo lapansi la ceramic ndi njira yotsekera madamu.

Makhalidwe a alumina ceramic gawo lapansi ndi awa:

1. Kupsinjika kwamphamvu ndi mawonekedwe okhazikika; Mkulu mphamvu, mkulu matenthedwe madutsidwe ndi kutchinjiriza mkulu; Kumanga kwamphamvu komanso anti-corrosion.

2. Kuchita bwino kwa kutentha kwapakati, ndi maulendo a 50000 ndi kudalirika kwakukulu.

3. Monga PCB bolodi (kapena IMS gawo lapansi), akhoza etch dongosolo la zithunzi zosiyanasiyana; Palibe kuipitsa ndi kuipitsa.

4. Ntchito kutentha osiyanasiyana: – 55 ℃ ~ 850 ℃; Coefficient of thermal expansion ili pafupi ndi silicon, yomwe imathandizira kupanga gawo la mphamvu.

Kodi ubwino wa alumina ceramic substrate ndi chiyani?

A. Thermal expansion coefficient of ceramic substrate ndi pafupi ndi silicon chip, yomwe ingapulumutse kusintha kosanjikiza Mo chip, kupulumutsa ntchito, zipangizo ndi kuchepetsa mtengo;

B. kuwotcherera wosanjikiza, kuchepetsa kukana matenthedwe, kuchepetsa patsekeke ndi bwino zokolola;

C. M’lifupi mzere wa 0.3mm wandiweyani mkuwa zojambulazo ndi 10% yokha ya bolodi wamba kusindikizidwa dera;

D. The matenthedwe madutsidwe chip chimapangitsa phukusi la chip kwambiri yaying’ono, amene kwambiri bwino kachulukidwe mphamvu ndi bwino kudalirika kwa dongosolo ndi chipangizo;

E. Mtundu (0.25mm) ceramic gawo lapansi lingalowe m’malo mwa BeO popanda chiwopsezo cha chilengedwe;

F. Large, 100A panopa mosalekeza akudutsa 1mm lonse ndi 0.3mm wandiweyani mkuwa thupi, ndi kutentha kukwera pafupifupi 17 ℃; 100A panopa mosalekeza akudutsa 2mm m’lifupi ndi 0.3mm wandiweyani mkuwa thupi, ndi kutentha nyamuka pafupifupi 5 ℃;

G. Low, 10 × The matenthedwe kukana 10mm ceramic gawo lapansi, 0.63mm wandiweyani ceramic gawo lapansi, 0.31k/w, 0.38mm wandiweyani ceramic gawo lapansi ndi 0.14k/w motero;

H. Kukanika kwakukulu, kuonetsetsa chitetezo chaumwini ndi chitetezo cha zida;

1. Zindikirani njira zatsopano zopangira ma CD ndi msonkhano, kuti zinthuzo zikhale zogwirizana kwambiri ndipo voliyumu imachepetsedwa.