- 25

- Mar

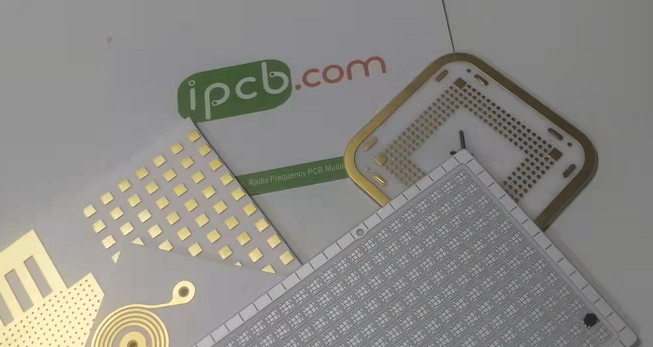

Alumina Ceramic PCB

Ndeapi mashandisirwo chaiwo ealumina ceramic substrate

MuPCB proofing, alumina ceramic substrate yakashandiswa zvakanyanya mumaindasitiri mazhinji. Nekudaro, mumashandisirwo chaiwo, ukobvu uye kutsanangurwa kwega yega alumina ceramic substrate zvakasiyana. Chii chiri chikonzero cheizvi?

1. Ukobvu hwealumina ceramic substrate inotarirwa maererano nekushanda kwechigadzirwa

Iyo yakakura kukora kwealumina ceramic substrate, zviri nani kusimba uye kusimba kwesimba rekudzivirira, asi iyo yekupisa conductivity yakaipisisa kupfuura iyo yakatetepa; Kusiyana neizvi, iyo yakaonda iyo alumina ceramic substrate, iyo simba uye kumanikidza kuramba haina kusimba seyakakora, asi iyo yekupisa conductivity yakasimba pane gobvu. Ukobvu hwealumina ceramic substrate inowanzoita 0.254mm, 0.385mm uye 1.0mm/2.0mm/3.0mm/4.0 Mm, nezvimwewo.

2. Izvo zvinotsanangurwa uye saizi yealumina ceramic substrates zvakare akasiyana

Kazhinji, alumina ceramic substrate idiki pane yakajairwa PCB bhodhi rose, uye saizi yayo kazhinji haipfuure 120mmx120mm. Awo anodarika saizi iyi kazhinji anoda kugadziridzwa. Uye zvakare, saizi yealumina ceramic substrate haisi iyo yakakura zvirinani, kunyanya nekuti substrate yayo inogadzirwa neceramics. Mukuita kwePCB proofing, zviri nyore kutungamira mukutsemuka kweplate, zvichikonzera kurasika kwakawanda.

3. Chimiro chealuminium ceramic substrate chakasiyana

Alumina ceramic substrates inowanzova imwe uye mbiri-mativi mahwendefa, ane rectangular, sikweya uye denderedzwa zvimiro. MuPCB proofing, zvinoenderana nezvinodiwa nehurongwa, vamwe vanofanirwawo kugadzira migodhi paceramic substrate uye nzira yekuvharisa madhamu.

Hunhu hwealumina ceramic substrate hunosanganisira:

1. Kushungurudzika kwakasimba uye chimiro chakagadzikana; Simba guru, high thermal conductivity uye high insulation; Kunamatira kwakasimba uye anti-corrosion.

2. Yakanaka yekupisa kutenderera kwekuita, ine 50000 cycles uye yakakwirira kuvimbika.

3. Kufanana nePCB board (kana IMS substrate), inogona etch chimiro chemifananidzo yakasiyana-siyana; Hapana kusvibiswa uye kusvibiswa.

4. Kushanda tembiricha siyana: – 55 ℃ ~ 850 ℃; Iyo coefficient yekuwedzera kwekupisa iri pedyo nesilicon, iyo inorerutsa maitiro ekugadzira emagetsi module.

Ndezvipi zvakanakira alumina ceramic substrate?

A. Thermal yekuwedzera coefficient yeceramic substrate iri pedyo neiyo yesilicon chip, iyo inogona kuchengetedza shanduko yekuchinja Mo chip, kuchengetedza basa, zvinhu uye kuderedza mutengo;

B. Welding layer, kuderedza kupisa kwekupisa, kuderedza mhango uye kunatsiridza goho;

C. Mutsetse wakafara we0.3mm gobvu foil yemhangura inongova 10% yeyakajairika yakadhindwa redunhu bhodhi;

D. Thermal conductivity of the chip inoita kuti pasuru ye chip ive yakanyanya compact, iyo inovandudza zvakanyanya kuwanda kwesimba uye inovandudza kuvimbika kwehurongwa uye mudziyo;

E. Type (0.25mm) ceramic substrate inogona kutsiva BeO pasina chepfu yezvakatipoteredza;

F. Yakakura, 100A ikozvino inoramba ichipfuura nepakati pe 1mm yakafara uye 0.3mm gobvu muviri wemhangura, uye tembiricha inokwira inenge 17 ℃; 100A ikozvino inoramba ichipfuura nepakati pe2mm yakafara uye 0.3mm gobvu muviri wemhangura, uye tembiricha inokwira ingangoita 5 ℃;

G. Yakaderera, 10 × Thermal resistance ye10mm ceramic substrate, 0.63mm gobvu ceramic substrate, 0.31k/w, 0.38mm gobvu ceramic substrate uye 0.14k/w zvichiteerana;

H. High pressure resistance, kuve nechokwadi chekuchengetedzwa kwemunhu uye kugona kuchengetedza michina;

1. Ziva mitsva yekuputira uye nzira dzegungano, kuitira kuti zvigadzirwa zvinyatsobatanidzwa uye ivhu rakaderedzwa.