- 12

- May

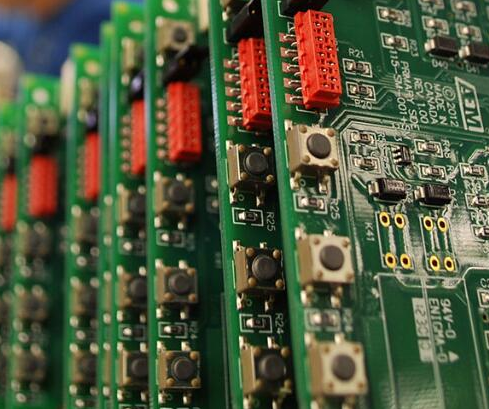

Zvinodiwa zvePCBA welding process

PCBA welding processing kazhinji ine zvakawanda zvinodiwa zvePCB board, izvo zvinofanirwa kusangana nezvinodiwa zvewelding. Saka nei iyo welding process ichida zvakawanda zvinodiwa zvemabhodhi edunhu? Chokwadi chakaratidza kuti kuchave neakawanda akakosha maitiro mukuita kwePCBA welding, uye kushandiswa kwemaitiro akakosha kunounza zvinodiwa kuPCB.

Kana PCB bhodhi ane matambudziko, kuchawedzera kuoma PCBA nomoto muitiro, uye zvinogona pakupedzisira kutungamirira nomoto kuremara, asina kukodzera mapuranga, etc. Naizvozvo, kuitira kuti ave nechokwadi kupedzwa kwakatsetseka kwezvinokosha maitiro uye kufambisa PCBA welding processing, PCB bhodhi. inofanirwa kusangana nezvinodiwa zvekugadzira maererano nehukuru uye pad kureba.

Tevere, ini ndichasuma zvinodikanwa zvePCBA welding process paPCB board.

Zvinodiwa zvePCBA welding process paPCB board

1. PCB saizi

Hupamhi hwePCB (kusanganisira mupendero webhodhi redunhu) hunofanira kunge hwakakura kupfuura 50mm uye isingasviki 460mm, uye kureba kwePCB (kusanganisira mupendero webhodhi redunhu) kunofanira kunge kwakakura kupfuura 50mm. Kana saizi yacho iri diki, inoda kugadzirwa kuita mapaneru.

2. PCB mupendero upamhi

Plate edge wide > 5mm, plate spacing <8mm, chinhambwe pakati pe base plate uye plate edge> 5mm.

3. PCB kukotama

Kupeta kumusoro: <1.2mm, kukotama pasi: <0.5mm, PCB deformation: kureba kwedeformation kureba ÷ diagonal kureba <0.25.

4. PCB mark point

Maka chimiro: chiyero denderedzwa, chikwere uye katatu;

Mako saizi: 0.8 ~ 1.5mm;

Maka zvinhu: goridhe plating, tin plating, mhangura uye platinamu;

Mark’s pamusoro pezvinodiwa: nzvimbo yacho yakati sandara, yakatsetseka, isina oxidation uye tsvina;

Zvinodiwa zvakatenderedza mucherechedzo: hapazovi nezvipingamupinyi zvakaita semafuta egirini izvo zviri pachena kuti zvakasiyana nemuvara wechiratidzo mukati me1mm kumativi;

Maka chinzvimbo: inopfuura 3mm kubva kumucheto kweplate, uye hapazove nemugomba, test point uye mamwe mamaki mukati me5mm.

5. PCB pad

Iko hakuna kuburikidza nemakomba pamapadhi eSMD zvikamu. Kana paine gomba, solder paste inoyerera ichipinda mugomba, zvichikonzera kuderedzwa kwerata mumudziyo, kana kuti tin inoyerera ichienda kune rimwe divi, zvichikonzera kusaenzana kwebhodhi pamusoro uye kusakwanisa kudhinda iyo solder paste.

MuPCB dhizaini nekugadzira, zvinodikanwa kuti unzwisise imwe PCB welding process ruzivo kuitira kuti zvigadzirwa zvikwane kugadzirwa. Chekutanga pane zvese, kunzwisisa zvinodikanwa zvechigadzirwa chekugadzira zvinogona kuita kuti inotevera gadziriso yekugadzira iwedzere kutsetseka uye kudzivirira dambudziko risingakoshe.

Izvo zviri pamusoro ndeye sumo kune zvinodiwa zvePCBA welding processing pamabhodhi ePCB. Ndinovimba inogona kukubatsira uye kuda kuziva zvakawanda nezve PCBA welding processing information.