- 25

- Mar

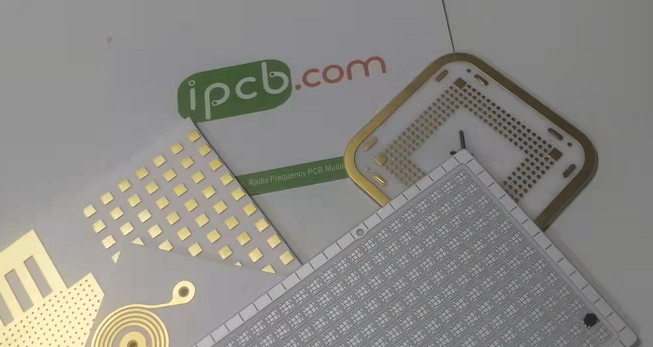

Alumina Ceramic PCB

Ke lisebelisoa life tse khethehileng tsa alumina ceramic substrate?

Bopaking ba PCB, substrate ea alumina ceramic e ‘nile ea sebelisoa haholo liindastering tse ngata. Leha ho le joalo, lits’ebetsong tse ikhethileng, botenya le sebopeho sa substrate ka ‘ngoe ea alumina ceramic li fapane. Lebaka la see ke lefe?

1. Botenya ba alumina ceramic substrate bo khethoa ho ea ka mosebetsi oa sehlahisoa

The botenya botenya ba alumina ceramic substrate, matla a betere le matla a ho hanyetsa khatello, empa conductivity ea mocheso e mpe ho feta ea e mosesaane; Ho e-na le hoo, e fokolang ea alumina ceramic substrate, matla le khatello ea khatello ha li matla joaloka tse teteaneng, empa conductivity ea mocheso e matla ho feta e teteaneng. Botenya ba substrate ea alumina ceramic ka kakaretso ke 0.254mm, 0.385mm le 1.0mm/2.0mm/3.0mm/4.0 Mm, joalo-joalo.

2. Litlhaloso le boholo ba li-substrates tsa alumina ceramic le tsona li fapane

Ka kakaretso, substrate ea alumina ceramic e nyane haholo ho feta boto e tloaelehileng ea PCB ka kakaretso, ‘me boholo ba eona hangata ha bo fete 120mmx120mm. Tse fetang boholo bona hangata li hloka ho hlophisoa. Ntle le moo, boholo ba alumina ceramic substrate ha bo kholo ho feta, haholo hobane substrate ea eona e entsoe ka lirafshoa. Ts’ebetsong ea bopaki ba PCB, ho bonolo ho lebisa ho petsoha ha poleiti, ho bakang litšila tse ngata.

3. Sebopeho sa alumina ceramic substrate se fapane

Li-substrates tsa alumina ceramic hangata ke lipoleiti tse nang le mahlakore a mabeli, tse nang le libopeho tse khutlonnetsepa, tse sekoere le tse chitja. Bopaking ba PCB, ho latela litlhoko tsa ts’ebetso, ba bang ba boetse ba hloka ho etsa li-grooves holim’a substrate ea ceramic le mokhoa oa ho koala letamo.

Litšobotsi tsa alumina ceramic substrate li kenyelletsa:

1. Khatello e matla le sebōpeho se tsitsitseng; Matla a phahameng, conductivity e phahameng ea mocheso le mocheso o phahameng; Ho khomarela ka matla le ho thibela ho bola.

2. Ts’ebetso e ntle ea potoloho ea mocheso, e nang le lipotoloho tsa 50000 le ho tšepahala ho phahameng.

3. Joaloka PCB boto (kapa IMS substrate), e ka etch sebopeho sa Grafiken tse sa tšoaneng; Ha ho tšilafalo le tšilafalo.

4. Boemo ba mocheso oa ho sebetsa: – 55 ℃ ~ 850 ℃; Coefficient ea katoloso ea mocheso e haufi le silicon, e nolofatsang ts’ebetso ea tlhahiso ea mojule oa matla.

Melemo ea alumina ceramic substrate ke efe?

A. Mocheso oa katoloso ea mocheso oa substrate ea ceramic e haufi le ea silicon chip, e ka bolokang lera la phetoho ea Mo chip, ho boloka mosebetsi, thepa le ho fokotsa litšenyehelo;

B. Welding layer, fokotsa ho hanyetsa mocheso, fokotsa cavity le ho ntlafatsa chai;

C. Bophara ba mohala oa foil ea koporo e teteaneng ea 0.3mm ke 10% feela ea boto e tloaelehileng e hatisitsoeng ea potoloho;

D. Thermal conductivity ea chip e etsa hore sephutheloana sa chip se kopane haholo, se ntlafatsang haholo matla a matla le ho ntlafatsa ho tšepahala ha tsamaiso le sesebelisoa;

E. Mofuta (0.25mm) substrate ea ceramic e ka nka sebaka sa BeO ntle le chefo ea tikoloho;

F. E kholo, 100A hona joale e tsoela pele ho feta 1mm ka bophara le 0.3mm ‘mele oa koporo o teteaneng,’ me mocheso oa mocheso o ka bang 17 ℃; 100A hajoale e ntse e feta ka bophara ba 2mm le ‘mele oa koporo o teteaneng oa 0.3mm, mme ho phahama ha mocheso ke hoo e ka bang 5 ℃ feela;

G. Low, 10 × Thermal resistance of 10mm ceramic substrate, 0.63mm teteaneng ea ceramic substrate, 0.31k / w, 0.38mm e teteaneng ea ceramic substrate le 0.14k / w ka ho latellana;

H. Ho hanyetsa khatello e phahameng, ho netefatsa tšireletso ea botho le bokhoni ba tšireletso ea lisebelisoa;

1. Lemoha mekhoa e mecha ea ho paka le ho kopanya, e le hore lihlahisoa li kopane haholo ‘me molumo o fokotsehe.