- 07

- Jun

Boto ea potoloho ke ea mofuta ofe o ikhethang?

Moralo oa potoloho ea mohala oa thekeng ke oa boqapi le theknoloji ea potoloho ea elektroniki.

Baithuti ba ipabolang ka moralo oa potoloho ea elektroniki le thekenoloji ba ka kenya letsoho moralong oa sehlahisoa le ho lokiseng tlhahiso ea li-circuits tsa elektroniki, tlhahiso e nepahetseng ea litšoantšo, ts’ebetso ea taolo ea lipalo, taolo ea ts’ebetso ea tlhahiso ea potoloho, tlhahlobo ea tlhahiso ea potoloho, taolo ea boleng le taolo ea tlhahiso ea potoloho lifekthering tsa elektroniki. kapa litsi tsa lipatlisiso. Ba ka boela ba kopanela ho reka le ho rekisa li-circuits tsa elektroniki le lisebelisoa tse tala le tse thusang, kopano ea likarolo tsa chip, joalo-joalo.

Ts’ebelisong ea mahlale a elektroniki a matla le lits’ebetso tse fapaneng tsa matla, theknoloji ea phepelo ea motlakase e ka sehloohong. Bakeng sa phepelo e kholo ea motlakase oa electrolytic, potoloho ea setso e kholo haholo ebile e boima. Haeba theknoloji ea phepelo ea motlakase ea Galton e amoheloa, bophahamo ba eona le boima ba eona bo tla fokotseha haholo, ‘me ts’ebeliso ea ts’ebeliso ea motlakase e tla ntlafatsoa haholo, lisebelisoa li tla bolokeha,’ me litšenyehelo li fokotsehe. Likoloing tsa motlakase le li-drive frequency drive, theknoloji ea phepelo ea motlakase e bohlokoa haholo. Ho fetola phepelo ea motlakase ho ka fetola maqhubu a motlakase, e le ho fihlela taolo e batlang e lekana ea mojaro le taolo ea koloi. Theknoloji ea phepelo ea motlakase ea maqhubu a phahameng ke theknoloji ea mantlha ea lisebelisoa tse fapaneng tsa matla a ho fetola matla a mangata (mochini oa welding oa inverter, phepelo ea motlakase ea puisano, phepelo ea motlakase e futhumatsang maqhubu a phahameng, phepelo ea motlakase ea laser, phepelo ea motlakase, jj.).

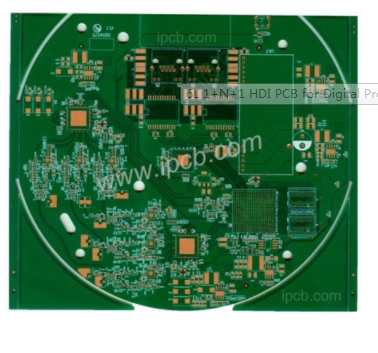

Seo indasteri e se etsang Ho etsa PCB tsa

Ho etsa PCB ke indasteri ea sejoale-joale ea elektroniki.

Boto ea potoloho e boetse e tsejoa e le PCB, substrate ea aluminium, boto e phahameng ea maqhubu, boto ea potoloho e hatisitsoeng, boto e tenyetsehang, joalo-joalo.

Lintho tse tala tsa boto ea potoloho ke fiber ea khalase, e ka bonoang bophelong ba rona ba letsatsi le letsatsi. Ka mohlala, motheo oa lesela le thibelang mollo le maikutlo a thibelang mollo ke fiber ea khalase. Fiber ea khalase e bonolo ho kopanngoa le resin. Re qoelisa lesela la fiber ea khalase ka sebopeho sa compact le matla a phahameng ka har’a resin ebe re le thatafatsa ho fumana substrate ea PCB e kentsoeng le ho se bonolo ho e koba – haeba boto ea PCB e robehile, mathoko a soeufetse ebile a koahetsoe, e leng ho lekaneng ho paka hore thepa ke resin khalase fiber.

Mekhoa e meraro ea nts’etsopele ea nakong e tlang ea indasteri ea PCB

1. Tlhokahalo ea likoloi tsa motlakase bakeng sa PCB e eketsehile haholo. Tlas’a tsamaiso ea mabili a mabeli a motlakase le a bohlale, ‘maraka oa lisebelisoa tsa elektroniki oa likoloi o eketsehile ka potlako, o boloka sekhahla sa kholo sa selemo se fetang 15% lilemong tsa morao tjena. Ka hona, ‘maraka oa PCB oa likoloi tsa makoloi o ntse o tsoela pele ho phahama.

2. Tlhokahalo ea indasteri ea puisano ea 5g e ntse e atamela. Matsete a kaho a China a 5g a tla fihla ho li-yuan tse limilione tse likete tse 705, e leng keketseho ea 56.7% ho feta matsete a 4G. Ha ho bapisoa le tsamaiso ea 2g-4g ea puisano, 5g e tla sebelisa haholo 3000-5000mhz le millimeter wave frequency band, ‘me e hloka hore sekhahla sa phetisetso ea data se eketsehe ka makhetlo a fetang 10. Kaho ea liteishene tse nyane tse teteaneng haholo tse hlahisitsoeng ke khoebo ea 5g e tla tlisa tlhokahalo e ngata ea PCB e phahameng haholo.

3. Lifono tse bohlale li na le tlhoko e eketsehileng ea FPC. FPC e tšesaane ebile e tenyetseha. Lisebelisoa tsa FPC li kenyelletsa antenna, khamera, pontšo ea module, touch module, joalo-joalo. Hajoale, theko ea selemo le selemo ea Apple ea li-account tsa FPC bakeng sa halofo ea karolo ea ‘maraka oa lefats’e. IPhone e ‘ngoe le e’ ngoe e sebelisa li-FPC tse ka bang 14-16, ‘me ASP e le’ ngoe e batla e le $30.

Ipcb ke moetsi ea nang le lilemo tse ngata tsa PCB boiphihlelo ba tlhahiso. E na le matla a ho etsa PCB a likarolo tse 1-40, joalo ka boto e thata, boto e bonolo, boto e kopaneng e thata, HDI le substrate ea tšepe. Lihlahisoa tsa eona li sebelisoa haholo taolong ea indasteri, ts’ireletso, ts’ebeliso, phepelo ea motlakase, lisebelisoa tsa elektroniki tsa likoloi le masimo a mang. Ke tšepa hore batho ba tsoang likarolong tsohle tsa bophelo ba hlokang lipatlisiso le nts’etsopele e kopanetsoeng.