- 25

- Apr

Explain Rogers 5880 laminated PCB material

Rogers 5880 laminate is made of the same high-quality and reliable materials and processes as Rogers, which makes Rogers win important awards from high-frequency material manufacturers. In some designs, the dielectric properties of PCB are very important. Whether it is high-speed, RF, microwave or mobile, power management is the key. You will find that the dielectric characteristics of the circuit board in the prototype are more needed than those not provided by the standard FR-4. We know. This is why we extend pcbexpress with rogers5880 dielectric materials. These new low loss dielectric materials mean higher performance for demanding PCB prototypes.

Why use Rogers dielectric material?

FR-4 material is the basic standard of PCB substrate, which can achieve an efficient balance between cost, manufacturing capacity, electrical performance and durability. But if electrical characteristics and advanced performance are the foundation of your design, Rogersmaterials is your ideal choice because:

Reduce dielectric loss

Low loss power consumption signal

Large range DK (dielectric constant) (2.55-10.2)

Low cost circuit manufacturing

Low air release space applications

Dielectric material

Dielectric material is a material with poor conductivity, which is used as an insulating layer in PCB structure. Some of the dielectric is mica, and some of the dielectric is mica, metal oxide, and plastic. The lower the dielectric loss (the energy lost in the form of heat), the more effective the dielectric material is. If the voltage in the dielectric material becomes too high, that is, when the electrostatic field becomes too strong, the material suddenly begins to conduct current. This phenomenon is called dielectric breakdown.

Properties of rtduroid5880

Very low loss opportunities for any electrical reinforced PTFE material

Ang pagsipsip ng mababang kahalumigmigan

Isotropy

Electrical performance with uniform frequency

Excellent chemical resistance, including solvents and reagents for printing and coating

Friendly na kapaligiran

Pre impregnation (pre preg)

The shrinkage of “pre impregnated composite fiber” and the production of PCB, pre PregS, will affect the performance characteristics of printed circuit board. A term used in the PCB manufacturing industry to describe the material of the adhesive layer used to connect layers, multilayer PCB.

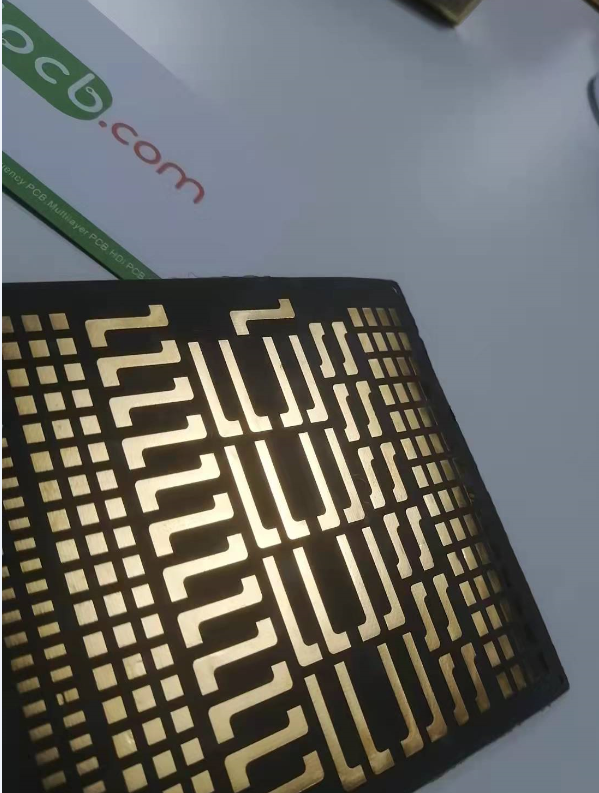

Rtduroid5880 high frequency laminate from Rogers

Rogers5880 high frequency laminate series adopts PTFE composite reinforced glass fiber. These microfibers are statistically oriented to maximize the advantages of fiber gain and provide the most valuable direction for circuit manufacturers and end-use applications. The dielectric constant of these high-frequency laminates is the lowest of all products, and the low dielectric loss makes them suitable for high-frequency / broadband applications where dispersion and loss must be minimized. Due to its extremely low water absorption, rtduroid5880 is very suitable for use in high humidity environment.

These advanced circuit materials can be easily cut, cut and processed to form any solvent and reagent commonly used in circuit boards or edge and hole electroplating. They have very low electrical loss for any reinforced PTFE material, and they also have very low moisture absorption and are isotropic. They have uniform electrical characteristics in frequency. High frequency rtduroid5880 is used in commercial airlines, microstrip and stripline circuits, millimeter wave system applications used in military radars, missile system antennas, digital radio point shows and others. The rtduroid5880 filled with PTFE compound is designed for the strict application of integrated circuits and microcircuits.

Rogerpcb material has the lowest DK value of copper laminate available on the market. Due to its low dielectric constant of 1.96 at 10GHz, rtduroid5880 supports broadband applications of microwave frequencies in the millimeter range, in which dispersion and circuit loss must be minimized. It is a single filled, lightweight PTFE composite with extremely low density (1.37G / cm3) and low coefficient of thermal expansion (CTE) on the z-axis. It can provide high-frequency manufacturing (PTH) holes and achieve higher payload. In addition, the dielectric constant from plate to panel is uniform and constant in a wide frequency range, and the z-axis tcdk is as low as + 22ppm / ° C.