- 25

- Mar

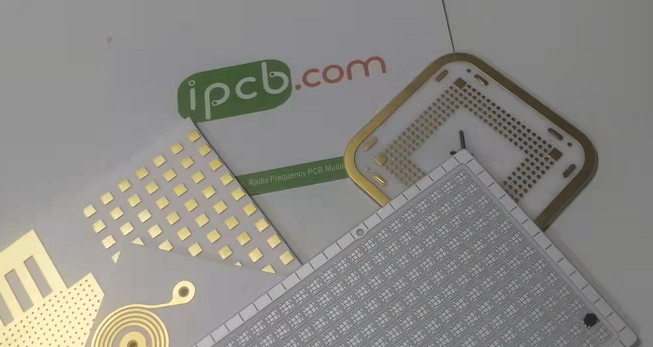

IAlumina Ceramic PCB

Ziziphi izicelo ezithile ze-alumina ceramic substrate

Kwi-PCB proofing, i-alumina ceramic substrate isetyenziswe ngokubanzi kumashishini amaninzi. Nangona kunjalo, kwizicelo ezithile, ubukhulu kunye nokucaciswa kwe-alumina ceramic substrate nganye yahlukile. Siyintoni isizathu soku?

1. Ubuninzi be-alumina ceramic substrate bunqunywe ngokomsebenzi wemveliso

Ukuqina kobunzima be-alumina ceramic substrate, kokukhona amandla angcono kwaye anamandla okumelana noxinzelelo, kodwa ukuhanjiswa kwe-thermal kubi kunoko kubhityileyo; Ngokuchasene noko, i-alumina ye-ceramic substrate incinci, amandla kunye noxinzelelo loxinzelelo alunamandla njengabo bunzima, kodwa ukuqhutyelwa kwe-thermal kunamandla kunezingqimba. Ubukhulu be-alumina ceramic substrate ngokubanzi yi-0.254mm, 0.385mm kunye ne-1.0mm/2.0mm/3.0mm/4.0 Mm, njl.

2. Iinkcukacha kunye nobukhulu be-alumina ceramic substrates nazo zahlukile

Ngokubanzi, i-alumina ceramic substrate incinci kakhulu kunebhodi eqhelekileyo yePCB iyonke, kwaye ubungakanani bayo abukho ngaphezu kwe-120mmx120mm. Ezo zigqithise kolu bukhulu ngokubanzi zifuna ukulungiswa. Ukongeza, ubungakanani be-alumina ceramic substrate ayiyona inkulu ngakumbi, ngakumbi kuba i-substrate yayo yenziwe ngeeseramics. Kwinkqubo yobungqina be-PCB, kulula ukukhokelela ekuqhekekeni kwepleyiti, okukhokelela kwinkunkuma eninzi.

3. Ubume be-alumina ceramic substrate yahlukile

I-alumina ye-ceramic substrates ubukhulu becala ngamacwecwe angawodwa namacala amabini, anemilo yoxande, yesikwere kunye nesetyhula. Kubungqina be-PCB, ngokweemfuno zenkqubo, abanye kufuneka benze i-grooves kwi-substrate ye-ceramic kunye nenkqubo yokuvalwa kwedama.

Iimpawu ze-alumina ceramic substrate ziquka:

1. Uxinzelelo olunamandla kunye nesimo esizinzileyo; Amandla aphezulu, i-conductivity ephezulu ye-thermal kunye ne-insulation ephezulu; Ukubambelela okuqinileyo kunye ne-anti-corrosion.

2. Ukusebenza kakuhle komjikelo we-thermal, kunye nemijikelezo ye-50000 kunye nokuthembeka okuphezulu.

3. Njengebhodi yePCB (okanye i-IMS substrate), inokuthi ifake ubume bemizobo eyahlukeneyo; Akukho ngcoliseko nongcoliseko.

4. Uluhlu lobushushu obusebenzayo: – 55 ℃ ~ 850 ℃; I-coefficient yokwandiswa kwe-thermal isondele kwi-silicon, eyenza lula inkqubo yokuvelisa imodyuli yamandla.

Ziziphi iingenelo ze-alumina ceramic substrate?

A. I-coefficient yokwandisa i-thermal ye-ceramic substrate isondele kwi-silicon chip, enokugcina i-transition layer Mo chip, igcine abasebenzi, izinto eziphathekayo kunye nokunciphisa iindleko;

B. Umaleko we-Welding, ukunciphisa ukuxhathisa kwe-thermal, ukunciphisa umgodi kunye nokuphucula isivuno;

C. Ububanzi bomgca we-0.3mm yefoyile yobhedu engqindilili yi-10% kuphela yebhodi yesekethe eprintiweyo eqhelekileyo;

D. I-thermal conductivity ye-chip yenza i-package ye-chip idibanise kakhulu, ephucula kakhulu amandla ombane kunye nokuphucula ukuthembeka kwenkqubo kunye nesixhobo;

E. Uhlobo (0.25mm) i-ceramic substrate inokutshintsha i-BeO ngaphandle kobuthi bendalo;

F. Enkulu, i-100A yangoku idlula ngokuqhubekayo kwi-1mm ububanzi kunye ne-0.3mm yomzimba wobhedu obunzima, kunye nokunyuka kweqondo lokushisa malunga ne-17 ℃; I-100A yangoku idlula ngokuqhubekayo kwi-2mm ububanzi kunye ne-0.3mm yomzimba wobhedu obunzima, kwaye ukunyuka kobushushu kumalunga ne-5 ℃ kuphela;

G. Phantsi, 10 × Ukumelana ne-thermal ye-10mm ye-ceramic substrate, i-0.63mm engqindilili ye-ceramic substrate, 0.31k / w, 0.38mm i-substrate ye-ceramic engqindilili kunye ne-0.14k / w ngokulandelelanayo;

H. Ukumelana noxinzelelo oluphezulu, ukuqinisekisa ukhuseleko lomntu kunye namandla okukhusela izixhobo;

1. Qaphela iindlela ezintsha zokupakisha kunye neendlela zokuhlanganisa, ukwenzela ukuba iimveliso zihlanganiswe kakhulu kwaye umthamo uyancipha.