- 13

- May

Ubushushu kunye namava endlela ye-BGA welding

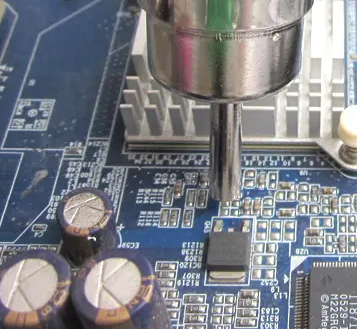

Okokuqala, ukuba i-glue ifakwe kwiikona ezine ze-chip kunye ne-chip ejikeleze i-chip, okokuqala ulungelelanise ukushisa kwe-hot-air gun ukuya kuma-degrees angama-330 kunye namandla omoya ubuncinci. Bamba umpu esandleni sakho sasekhohlo kunye ne-tweezers esandleni sakho sasekunene. Ngelixa uvuthela, unokuthatha iglu nge-tweezers. Zombini iglue emhlophe kunye neglue ebomvu inokususwa ngexesha elifutshane. Lilumkele ixesha oyenza ngalo, nexesha lokuvuthela kwayo

Ayinakuba yinde kakhulu. Ubushushu bokuluma buphezulu. Ungayenza ngokukhawuleza. Yenza oko okwethutyana, yima okwethutyana. Ukongeza, xa ukhetha i-tweezers, kufuneka uqaphele. Iglu ayithambisanga kwaye awukwazi ukukhetha ngamandla. Kufuneka ulumkele ukukrwela ibhodi yesekethe. Ukuba kuyenzeka, ungasebenzisa iglu ukuthambisa iglu, kodwa ndicinga ukuba usasebenzisa umpu womoya oshushu we-BGA welding yiza kwakamsinya.

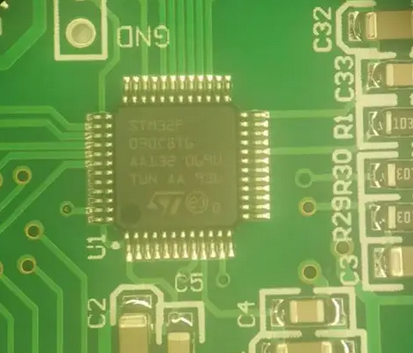

Makhe sithethe ngamanyathelo onke okwenza ibhentshi yokulungisa i-BGA. Ndiyakwazi ukuphumelela ukwenza ibhentshi yokulungisa i-BGA ngale ndlela, kunye nokwehla kwenqaku kunqabile. Masithathe kwakhona ikhadi lemizobo njengomzekelo.

Makhe sithethe ngamanyathelo am kwi-BGA:

1. Okokuqala, yongeza isixa esifanelekileyo somgangatho ophezulu we-BGA Solder Paste malunga nekhadi lemizobo, setha ubushushu bompu womoya oshushu ukuya kuma-degrees angama-200, unciphise amandla omoya, uvuthele ngokuchasene ne-solder paste, kwaye ngokukhawuleza uvuthele i-solder paste. itshiphu yekhadi lemizobo. Emva kokuba intlama ye-solder ijikeleze i-chip yekhadi lemizobo ivuthelwe phantsi kwe-chip, hlengahlengisa amandla omoya ompu womoya oshushu ukuya phezulu kwaye ujongane ne-chip kwakhona.

Injongo yoku kukwenza i-solder incamathelise nzulu kwi-chip.

Ubushushu kunye namava endlela ye-BGA welding

2. Emva kokuba la manyathelo angasentla egqityiwe, linda ukuba i-chip iphole ngokupheleleyo (ibaluleke kakhulu), kwaye emva koko usule i-solder engaphezulu kunye nokujikeleza i-chip yekhadi lemifanekiso kunye nomqhaphu wotywala. Qiniseka ukuba uyisule icocekile.

3. Emva koko, iphepha leplatinam lincanyathiselwa kwitshiphu. Ukuqinisekisa ukuba ubushushu obuphezulu ngexesha le-welding aluyi kulimaza i-capacitor, ityhubhu yentsimi kunye ne-triode ejikeleze ikhadi lemizobo, kunye ne-crystal oscillator, ngakumbi imemori yevidiyo ejikeleze ikhadi legraphics, iphepha le-tin platinum kufuneka lifakwe kwi-15 layers ngexesha. I-Beiqiao. Iphepha lam le-tin yeplatinam lincinci, kwaye andazi ukuba ilunge kangakanani ifuthe lokufakelwa kwe-thermal xa iileya ezili-15 zeplatinum zincanyathiselwa,

Kodwa kufuneka isebenze. Ubuncinci ngalo lonke ixesha xa usenza i-BGA, kwakungekho ngxaki kwimemori yevidiyo ecaleni kwekhadi lemizobo kunye neBhulorho yaseNyakatho, kwaye ayizange idityaniswe kwaye iqhume.

Ubushushu kunye namava endlela ye-BGA welding

Ukuba iqonga lokulungisa le-BGA lekhadi lemizobo alikakhanyiswa emva kokuba ligqityiwe, ndinokuqiniseka ukuba aligqitywanga. Andiyi kuthandabuza ukuba imemori yevidiyo elandelayo okanye i-North Bridge yonakele. Ngasemva kwitshiphu yekhadi lemizobo, iphepha leplatinam kufuneka lincanyathiselwe. Ndidla ngokuyincamathisela kumgangatho wesihlanu. Kwaye indawo inkulu kancinane. Oku kukuthintela xa usenza ibhentshi yokulungisa iBGA

, izinto ezincinci ezingasemva kwitshiphu ziyawa xa zishushu. Ukuncamathelisa iileya ezininzi kungcono kunokuncamathela umaleko omnye. Ukuba unamathele uluhlu olulodwa, ukushisa okuphezulu kuya kunyibilika ngokupheleleyo iglue kwiphepha le-tin kwaye linamathele ebhodini, elibi kakhulu. Ukuba uncamathisela iileya ezininzi, lo mcimbi awuzukubonakala.