- 01

- Jun

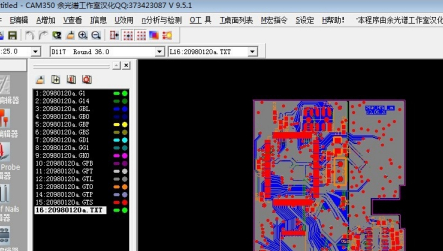

Intsingiselo kunye nomsebenzi we-PCB layers

1. Umaleko wokugrumba: umaleko wokugaya ubonelela ngolwazi lokugaya ngexesha lokwenziwa kwenkqubo yokwenziwa kwe Ishicilelwe yiBhodi yeSekethe (umzekelo, umngxuma odlulayo wepadi kufuneka ugrunjwe).

2. Uluhlu lweSignali: umgca wesignali usetyenziswa kakhulu ukulungiselela iingcingo kwibhodi yesekethe.

3. Imaski yesoda: sebenzisa umaleko wepeyinti, njengemaski yesolder, kuwo onke amalungu ngaphandle kwephedi ukuthintela inkonkxa ukuba ingafakwa kula malungu. Imaski ye-solder isetyenziselwa ukufanisa iphedi kwinkqubo yoyilo kwaye yenziwe ngokuzenzekelayo.

4. I-Solder paste umaleko okhuselayo, i-s-md patch layer: inomsebenzi ofanayo kunye ne-solder resist layer, ngaphandle kwe-pad yokudibanisa ehambelanayo yamacandelo adityanisiweyo ngexesha le-welding yomatshini.

5. Umaleko wocingo owalelweyo: usetyenziselwa ukuchaza indawo apho amacandelo kunye neengcingo zinokubekwa ngokufanelekileyo Ishicilelwe yiBhodi yeSekethe. Zoba indawo evaliweyo kulo maleko njengendawo esebenzayo yocingo. Ayinakubekwa ngokuzenzekelayo kwaye ihanjiswe ngaphandle kwale ndawo.

6. Umaleko wesikrini sesilika: umaleko wesikrini sesilika usetyenziswa ikakhulu ukubeka ulwazi loshicilelo, olufana nolwandlalo kunye nokumakishwa kwamacandelo, iimpawu ezahlukeneyo zochazo, njl. umaleko woshicilelo unokuvalwa.

7. Unikezelo lwangaphakathi lwangaphakathi / umaleko wokumisa: olu hlobo lomaleko lusetyenziselwa kuphela iibhodi ezininzi kwaye lusetyenziselwa ukucwangcisa iingcingo zombane kunye neengcingo zokumisa. inani lomaleko wesiginali kunye namandla angaphakathi / umaleko wokumisa.

8. I-Mechanical layer: isetyenziselwa ngokubanzi ukuseta imilinganiselo yonke, amanqaku edatha, amanqaku okulungelelaniswa, imiyalelo yendibano kunye nolunye ulwazi lomatshini webhodi yesekethe. Ulwazi luyahluka ngokweemfuno zenkampani yoyilo okanye PCB umenzi. Ukongeza, umaleko womatshini unokudityaniswa kwezinye iileya ukuvelisa umboniso kunye.