- 25

- Mar

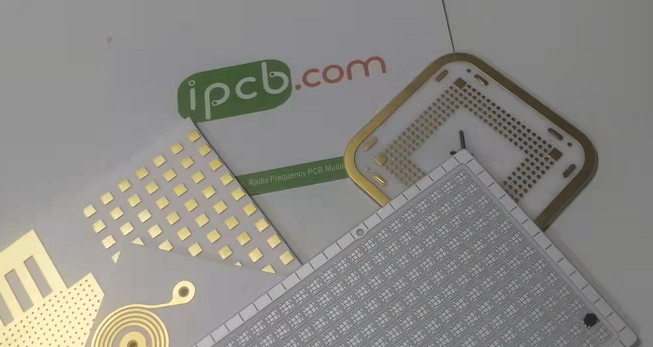

I-Alumina Ceramic PCB

Yiziphi izinhlelo zokusebenza ezithile ze-alumina ceramic substrate

Ekuqinisekiseni i-PCB, i-alumina ceramic substrate isetshenziswe kabanzi ezimbonini eziningi. Kodwa-ke, ekusetshenzisweni okukhethekile, ubukhulu kanye nokucaciswa kwe-alumina ceramic substrate ngayinye kuhlukile. Siyini isizathu salokhu?

1. Ubukhulu be-alumina ceramic substrate bunqunywa ngokusho komsebenzi womkhiqizo

Ukuqina kokuqina kwe-alumina ceramic substrate, amandla angcono futhi kunamandla ukumelana nokucindezela, kodwa ukuqhutshwa kokushisa kubi kakhulu kunokwencanyana; Ngokuphambene nalokho, i-alumina ceramic substrate izacile, amandla nokumelana nokucindezela akunamandla njengamanye aminyene, kodwa ukuguquguquka okushisayo kunamandla kunokuqina. Ugqinsi lwe-alumina ceramic substrate ngokuvamile luyi-0.254mm, 0.385mm kanye no-1.0mm/2.0mm/3.0mm/4.0 Mm, njll.

2. Ukucaciswa nobukhulu be-alumina ceramic substrates nakho kuhlukile

Ngokuvamile, i-alumina ceramic substrate incane kakhulu kunebhodi le-PCB elivamile lilonke, futhi ubukhulu bayo ngokuvamile abukho ngaphezu kuka-120mmx120mm. Lezo ezeqa lo sayizi ngokuvamile zidinga ukwenziwa ngendlela oyifisayo. Ngaphezu kwalokho, ubukhulu be-alumina ceramic substrate abuyona enkulu kangcono, ikakhulukazi ngoba i-substrate yayo yenziwe nge-ceramics. Enqubweni yokuhlola i-PCB, kulula ukuholela ekuhlukaneni kwamapuleti, okuholela ekumosheni okuningi.

3. Ukuma kwe-alumina ceramic substrate kuhlukile

Ama-substrates e-alumina ceramic ngokuvamile amapuleti angawodwa futhi anezinhlangothi ezimbili, anomumo ongunxande, oyisikwele kanye noyisiyingi. Ekuqinisekiseni i-PCB, ngokwezidingo zenqubo, abanye badinga futhi ukwenza imifantu ku-substrate ye-ceramic kanye nenqubo yokuvala idamu.

Izici ze-alumina ceramic substrate zifaka:

1. Ukucindezeleka okunamandla nesimo esizinzile; Amandla aphezulu, izinga eliphezulu le-thermal conductivity kanye nokufakwa okuphezulu; Ukunamathela okuqinile kanye ne-anti-corrosion.

2. Ukusebenza kahle komjikelezo oshisayo, nemijikelezo engu-50000 nokuthembeka okuphezulu.

3. Njengebhodi le-PCB (noma i-IMS substrate), lingakwazi ukufaka ukwakheka kwehluzo ezihlukahlukene; Akukho ukungcola nokungcola.

4. Izinga lokushisa elisebenzayo: – 55 ℃ ~ 850 ℃; I-coefficient yokunwetshwa kwe-thermal iseduze ne-silicon, eyenza inqubo yokukhiqiza yemojuli yamandla ibe lula.

Yiziphi izinzuzo ze-alumina ceramic substrate?

A. Icoefficient yokwandisa okushisayo ye-ceramic substrate iseduze naleyo ye-silicon chip, engasindisa ungqimba lwe-Mo chip, yonge abasebenzi, izinto zokwakha futhi yehlise izindleko;

B. Isendlalelo se-Welding, sinciphisa ukumelana nokushisa, sinciphise umgodi futhi sithuthukise isivuno;

C. Ububanzi bomugqa we-foil yethusi ewugqinsi engu-0.3mm buyi-10% kuphela yalolo lwebhodi lesekethe eliphrintiwe elijwayelekile;

D. I-thermal conductivity ye-chip yenza iphakheji ye-chip ihlangane kakhulu, ethuthukisa kakhulu ukuminyana kwamandla futhi ithuthukise ukuthembeka kwesistimu nedivayisi;

E. Uhlobo (0.25mm) i-ceramic substrate ingangena esikhundleni se-BeO ngaphandle kobuthi bemvelo;

F. Enkulu, engu-100A yamanje idlula ngokuqhubekayo emzimbeni wethusi ongu-1mm ububanzi no-0.3mm, futhi izinga lokushisa likhuphuka licishe libe ngu-17 ℃; I-100A yamanje idlula ngokuqhubekayo emzimbeni wethusi ongu-2mm ububanzi no-0.3mm, futhi izinga lokushisa likhuphuka lingaba ngu-5 ℃ kuphela;

G. Okuphansi, 10 × Ukumelana okushisayo kwe-substrate ye-ceramic engu-10mm, i-substrate ye-ceramic ewugqinsi engu-0.63mm, 0.31k/w, 0.38mm i-ceramic substrate ewugqinsi kanye no-0.14k/w ngokulandelanayo;

H. Ukumelana nokucindezela okuphezulu, ukuqinisekisa ukuphepha komuntu siqu kanye nekhono lokuvikela imishini;

1. Qaphela izindlela ezintsha zokupakisha nezindlela zokuhlanganisa, ukuze imikhiqizo ihlanganiswe kakhulu futhi ivolumu iyancipha.