- 27

- Apr

Yini okufanele siyinake ekucubunguleni kwe-PCBA? Amaphuzu adinga ukunakwa ekucutshungulweni kwe-PCBA

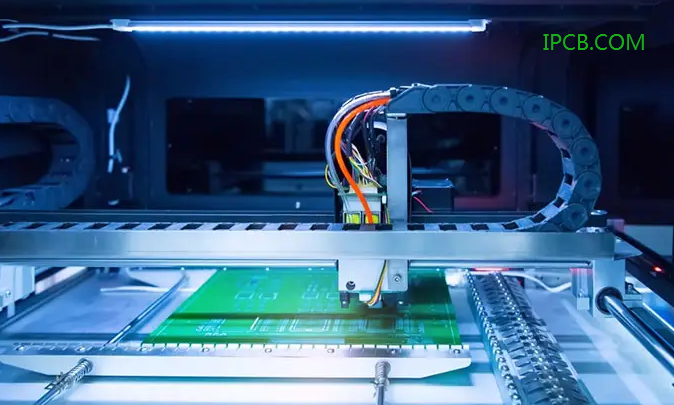

Ubufakazi be-SMT ngumkhiqizi ochwepheshe wokucubungula we-PCBA onefektri yayo ye-PCB Factory kanye ne-SMT patch processing factory, enganikeza PCBA eyodwa-stop izinsiza zokucubungula ezifana nokuqinisekisa kwe-PCB, ukuthengwa kwezingxenye, isichibi se-SMT, i-plug-in ye-dip, ukuhlolwa kwe-PCBA, ukuhlanganisa umkhiqizo oqediwe nokunye. Nazi izinto ezidinga ukunakwa ekucutshungulweni kwe-PCBA.

Izinkinga okufanele zibhekwe ekukhiqizeni i-PCBA

1. Idizayini yokudluliswa kwebhodi elilodwa kanye nezici zokubeka endaweni yomugqa wokukhiqiza othomathikhi

Ngokuhlanganiswa komugqa wokukhiqiza okuzenzakalelayo, i-PCBA kufanele ibe nekhono lokudlulisa izimpawu zokuma ezinqenqemeni nezokubona, okuyimfuneko yokukhiqiza.

2. PCBA umhlangano inqubo design

Isakhiwo sesakhiwo sezingxenye ngaphambili nangemuva kwe-PCBA sinquma indlela yenqubo nendlela ngesikhathi sokuhlangana.

3. Idizayini yesakhiwo sengxenye

Dizayina indawo, isiqondiso kanye nesikhala sezingxenye endaweni yomhlangano. Ukuhlelwa kwezingxenye kuncike endleleni ye-welding eyamukelwayo. Indlela yokushisela ngayinye inezidingo ezithile zokuma kwesakhiwo, isiqondiso kanye nesikhala sezingxenye.

4. Assembly inqubo design

Ukuze umklamo we-welding udlule ngesilinganiso, ngomklamo ofanayo we-pad, i-resistance welding kanye nensimbi yensimbi, ukusabalalisa okuzinzile kwe-quantitative kanye ne-fixed-point of solder paste kuyabonakala; Ngokuklanywa kwesakhiwo kanye ne-wiring, ukuncibilika okuhambisanayo nokuqina kwawo wonke amalunga e-solder ephaketheni elilodwa kungenziwa; Ngomklamo wokuxhumana ozwakalayo wembobo efakwayo, izinga lokungena likathayela elingama-75% lingafinyelelwa. Lezi zinhloso zokuklama ekugcineni zithuthukisa isivuno se-welding.

Izinyathelo zokuphepha ze-PCBA welding

1. Umgcini wempahla kufanele agqoke amagilavu aphikisana ne-static lapho ekhipha izinto zokwakha futhi ehlola i-IQC, futhi ithuluzi kufanele lisekelwe ngokuthembekile, futhi ithebula lokusebenza lizogandaywa ngephedi yenjoloba ephikisana ne-static kusengaphambili.

2. Ngesikhathi sokusebenza, kusetshenziswa i-anti-static worktops, futhi iziqukathi ze-anti-static zisetshenziselwa ukubamba izingxenye kanye nemikhiqizo eqediwe kancane. Imishini yokushisela yoMnyango ingamiswa phansi, futhi i-ayina yokunamathisela kagesi idinga ukuba uhlobo oluphikisana ne-static. Zonke izinto zokusebenza kufanele zihlolwe ngaphambi kokusetshenziswa.

3. Uma i-PCBA icutshungulwa esithandweni somlilo, ngenxa yokuthi izikhonkwane zezinto ze-plug-in zigezwa ukugeleza kwethayela, ezinye izici ze-plug-in zizotsheka ngemva kokushisela, okuholela ekutheni umzimba we-elementi weqe ifremu yesikrini sikasilika. Ngakho-ke, abasebenzi be-welding yokulungisa ngemuva kwesithando somlilo bayadingeka ukuze balungise kahle.

4. Uma i-PCBA iwukushisela uphondo nebhethri, kufanele kuqashelwe ukuthi i-solder joint ngeke ibe ningi kakhulu, engeke ibangele ukujikeleza okufushane noma ukuwa kwezingxenye ezizungezile.

5. Ama-substrates e-PCBA azobekwa ngobunono, futhi amapuleti angenalutho awakwazi ukupakishwa ngokuqondile. Uma ukupakishwa kuyadingeka, kuzopakishwa ezikhwameni ze-electrostatic.

Izinyathelo zokuphepha zomhlangano womkhiqizo ophelile we-PCBA

1. Wonke umshini ngaphandle kwegobolondo usebenzisa isikhwama sokupakisha esine-anti-static

Hlola njalo amathuluzi e-anti-static, izilungiselelo nezinto zokwakha ukuze uqinisekise ukuthi isimo esisebenzayo sihlangabezana nezidingo.

2. Uma uhlanganisa imikhiqizo eqediwe, landela izinqubo ezilandelayo

Indawo yokugcina impahla → ulayini wokukhiqiza → isofthiwe yokuthuthukisa umugqa wokukhiqiza → ukuhlanganisa emshinini ophelele → ukuhlolwa kwe-QC → bhala inombolo ye-IMEI → Ukuhlola okugcwele kwe-QA → buyisela izilungiselelo zasefekthri → indawo yokugcina impahla; Isoftware izothuthukiswa ngaphambi kokuhlanganiswa. Ngeke ihlanganiswe emshinini oqediwe bese ithuthukiswa. Ingase ingathuthukiswa ngenxa ye-welding engafanele, i-short circuit, izinkinga zenqubo yokusebenza, njll., okuholela ekwahluleleni okungalungile kwe-PCBA embi.

Okungenhla yilokho okudinga ukunakwa ekucutshungulweni kwe-PCBA? Ukucubungula kwe-PCBA kudinga ukunaka ukwethulwa kwamaphuzu, ngithemba ukuthi kungakusiza.