- 27

- May

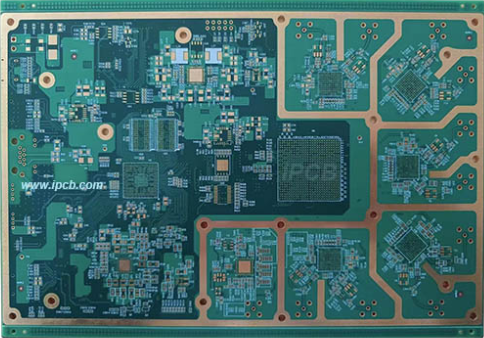

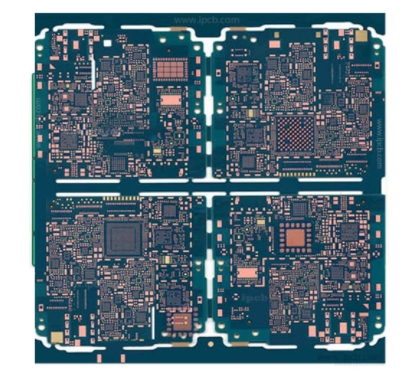

Mastering High-Performance PCB Design: Essential Requirements and Challenges

Introduction:

High-performance PCB (Printed Circuit Board) design is critical for creating reliable, efficient, and high-speed electronic products. This process involves several technical requirements and challenges, making it essential to use advanced EDA (Electronic Design Automation) tools and have a solid understanding of both hardware fundamentals and specific design principles. In this blog, we’ll explore the key aspects of high-performance PCB design, with a focus on leveraging advanced tools like Cadence’s PSD series.

Advanced EDA Tool Software: The Backbone of High-Performance PCB Design

Modern PCB design relies heavily on powerful EDA tools. Cadence’s PSD series is a prime example, offering robust features that support high-speed PCB design. These tools include front and rear simulation modules to ensure signal quality, improving the first-time success rate of the product. Additionally, they utilize physical and electrical rules to intelligently implement technical requirements such as differential wiring and isometric control. Key benefits include:

- Signal Quality Assurance: Front and rear simulation modules help in maintaining signal integrity.

- Rule-Based Design: Physical and electrical rules automate complex tasks like differential wiring and length matching.

- Parallel Design Support: Speeds up development by allowing multiple design processes to run concurrently.

- Module Reuse: Enhances efficiency and ensures design consistency through the reuse of verified modules.

The Essential Hardware Foundation

Despite the shift towards high-speed signal integrity based on transmission line theory, fundamental hardware knowledge remains indispensable. Both IC and PCB engineers need a solid understanding of basic components like resistors (R), inductors (L), capacitors (C), and gate circuits. Knowledge in areas such as high-frequency and low-frequency circuits, digital circuits, microwaves, electromagnetic fields, and waves is crucial. A firm grasp of the basics ensures the following:

- Effective Power Supply Design: Understanding power supply principles is critical for reliable PCB operation.

- Signal Integrity Analysis: Signal integrity issues are often rooted in basic component behavior and circuit theory.

The High-Speed Challenge

As signal rates increase, maintaining signal integrity becomes increasingly challenging. Issues such as bus drive capability, signal reflection, crosstalk, overshoot, oscillation, and attenuation can all affect performance. Timing is also a crucial aspect of signal integrity. Cadence’s Allegro tool with its Signoise simulation module addresses these challenges by:

- Simulation and Verification: Building topologies for simulation and verifying wiring effects.

- Real-Time Alerts: Providing immediate feedback when design constraints are not met.

Power Supply and Ground Noise

Power and ground planes serve as reference planes for signal lines. Noise from these planes can directly affect signal integrity. Addressing power supply noise involves:

- Clarifying the Power Tree: Analyzing the power supply channel for rationality.

- Current Carrying Capacity: Ensuring adequate wiring width for large currents while considering voltage drops and the impact on power supply effectiveness.

- Filtering Effects: Considering impedance and the distribution of power to gate circuits.

EMC Issues

Electromagnetic Compatibility (EMC) has become a critical consideration due to increasing concerns about electromagnetic pollution. High-performance PCB design must address EMC from the start to ensure compliance and minimize interference. While simulation software provides valuable insights, it’s often necessary to:

- Design from the Source: Focus on minimizing emissions and interference from the PCB itself.

- Real-World Testing: Supplement simulation with actual measurements to ensure compliance with EMC standards.

The Challenge of DFM (Design for Manufacturability)

DFM ensures that PCB designs are manufacturable within the constraints of production capabilities. To address DFM challenges:

- Process Standards: Develop and adhere to process standards that suit the company’s capabilities.

- Comprehensive Training: Equip PCB designers with current knowledge of PCB production and processing capabilities.

- Library Management: Maintain a dedicated library building module to design package libraries and pads accurately.

By addressing these areas, high-performance PCB design can meet the stringent demands of modern electronic products, ensuring reliability, efficiency, and compliance with industry standards.

Conclusion

High-performance PCB design is a complex but rewarding field that requires a combination of advanced tools, fundamental hardware knowledge, and meticulous attention to design principles. By leveraging tools like Cadence’s PSD series and understanding the challenges and solutions associated with high-speed design, power supply noise, EMC, and DFM, engineers can create robust and reliable PCBs that meet the needs of today’s high-speed electronic devices.

Embrace these principles and tools to master high-performance PCB design and drive your electronic innovations to success.