- 20

- Oct

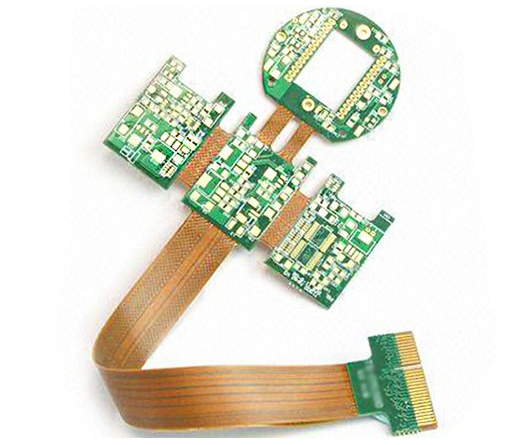

How is the Rigid-Flexible board processed?

Rigid-Flexible PCB is FPC flexible circuit board and PCB rigid circuit board after pressing and other processes, according to the relevant technical requirements combined together, the formation of FPC characteristics and PCB characteristics of the printed circuit board. RF PCB processing should have both FPC production equipment and PCB production equipment, the production process is more complex. After the CAM engineers to deal with the relevant documents, planning, arrangements for FPC production lines to produce the required FPC, PCB production lines to produce PCB; FPC and PCB samples out, in accordance with the planning requirements of the drawings, FPC and PCB through the press seamless compression, and then a series of details, and ultimately made of soft and hard junction board.

- Punching is in the FR4 circuit board and PP film above the drill holes in the alignment holes above the design and the general guide hole do not the same. After punching is completed, it needs to be browned.

- Hop will be summer copper, PP film, FPC circuit boards for stacking and placement and alignment of the position put neatly, the original old process is a step-by-step stacked production pressure table, but more time-consuming. After many attempts to find a stacking process can be completed.

- lamination is a combination of hard and soft board production is more complete step, most of the materials for the first time for the integration of the first will be the bottom of the love of copper and PP film, the top of the previous process of production of the FPC soft board, in the FPC soft board on top of the placing of a layer of PP film, and then placed in the last layer of copper-clad board. All the materials to be laminated are placed in order to complete the press.

- Gong board edge (also called in addition to the edge of the material) is the edge of the PCB circuit board location no line later also do not intend to make the line part of the removal. After that, we should measure whether the material has excessive shrinkage, due to the timely production of flexible boards using PI is also the existence of shrinkage, which is very big impact on the production of circuit boards.

- Drilling this step is the whole PCB circuit board for conduction of a step before the step, the production parameters should be made according to the design parameters.

- In addition to the slag is the use of plasma processing first PCB board drilling of the slag produced by the removal of the use of plasma cleaning will guide through the holes and clean the board surface.

- Copper sinking this step is the process of plating through-hole, also known as hole metallisation. Realise through-hole power conduction.

- PCB board surface plating is plated on the surface of the hole above the local plating hole copper, so that the through-hole above the copper thickness over the surface of the summer copper board to a certain height.

- The outer dry film production and FPC flexible board and the production process of resist dry film, the production of the line will be etched on the copper-clad laminate. Developed after the completion of the line check.

- Graphic plating etching, that is, after the initial copper plating, graphic plating, according to the design requirements using the current time and copper-plated line, to reach a certain plating area after alkaline etching out of the line.

- Print solder resist this step and soft board protective film is a same effect, we see the PCB hard board is generally green is this step, generally also known as printing green oil, printing is completed after the inspection. There are also customers require other solder resist ink, such as: butter, blue oil, red oil, white oil, black oil, etc., there are light-sensitive and matte.

- Gong open cover is also called open cover plate, that is, the area where the soft board is located, but the hard board does not need the area for laser cutting, so that the soft board is exposed.

- Surface treatment of immersion gold, spray tin, OSP, immersion silver, immersion tin, gold-plated, etc., usually at this time a combination of flexible and rigid boards (FPCB) has been produced, only need to be metallised on the surface of the circuit boards can play a role in preventing wear and tear oxidation.

The above are some key processes for the processing of rigid-flexible boards. Rigid-flex boards can be used in some products with special requirements, which can save the internal space of the product, reduce the volume of the finished product, and improve the performance of the product with great help.

iPCB circuit can provide customers with a combination of hard and soft board sampling batch processing services to meet the needs of customers in a variety of hard and soft combination of board sampling.