- 28

- Jan

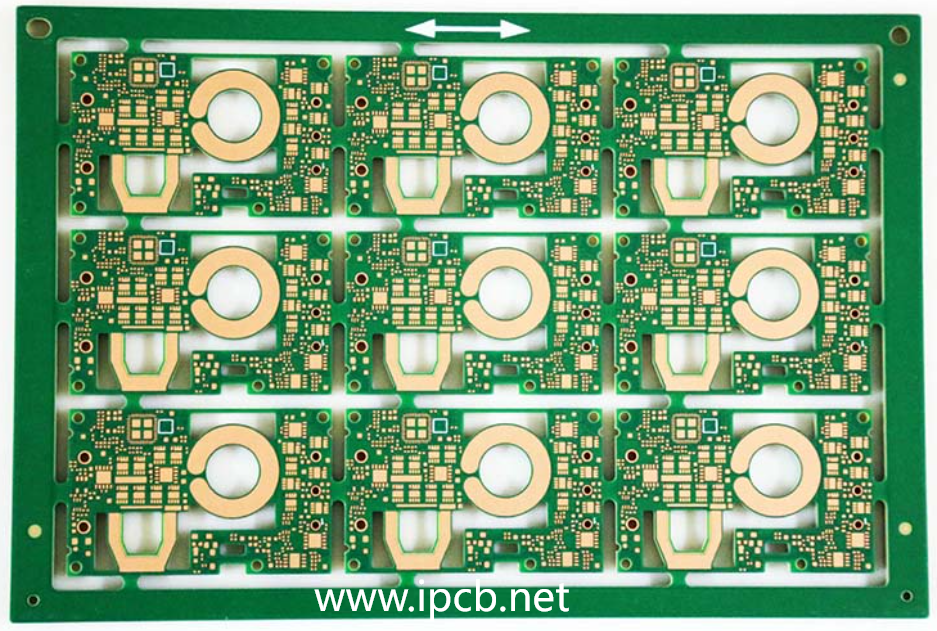

Advancements in PCB Interconnection Technology

Introduction:

Printed Circuit Boards (PCBs) serve as the backbone of electronic devices, enabling the seamless flow of electrical signals and ensuring the proper functioning of intricate circuits. Among the various technologies employed in PCB design, interconnection plays a pivotal role in determining the performance and efficiency of the final product. In this article, we will delve into the application of PCB interconnection technologies, with a focus on traditional plated through holes, buried holes, and blind holes.

1. Traditional Plated Through Holes:

The backbone of interlayer interconnection, traditionally plated through holes is a cost-effective and widely used technology. In this method, holes are drilled through the entire PCB panel, connecting layers irrespective of the need for an electrical connection. However, a significant drawback is that these vias occupy valuable space across all layers, even when not necessary for electrical connectivity.

2. Buried Holes:

Buried holes address the spatial inefficiency of traditional plated through holes. These plated-through holes connect multiple layers within the circuit board but remain hidden in the board’s inner structure, not surfacing on the outer layer. The advantage lies in space savings, especially crucial in scenarios with high signal line density. Despite offering increased circuit density, the complexity of the buried hole process incurs higher manufacturing costs.

3. Blind Holes:

Blind vias present a versatile solution by connecting the surface of a multi-substrate to one or more inner layers without traversing the entire thickness of the board. Unlike traditional plated through holes, blind holes save space and enable connectivity on both sides of the multi-substrate. They are particularly beneficial for components like surface mount devices (SMD) and connectors, where only small vias are required, offering more design space without the need for large component holes. Additionally, blind holes can be stacked, allowing for smaller and more intricate designs.

Applications:

- Signal Line Density: Buried holes and blind holes are advantageous in scenarios with high signal line density. Buried holes efficiently connect multiple layers, while blind holes provide a space-saving alternative for connecting surface layers.

- Component Size and Weight: For components like SMDs and connectors, blind via technology proves invaluable. It eliminates the need for large component holes, reducing weight and providing designers with ample space for creative designs.

- Cost Considerations: While traditional plated through holes are cost-effective, buried holes and blind holes, with their additional process steps, incur higher manufacturing costs. The decision between them depends on the specific requirements of the PCB design.

In conclusion, the choice of interlayer interconnection technology significantly influences the performance, cost, and design possibilities of PCBs. Designers must carefully evaluate the trade-offs between traditional plated through holes, buried holes, and blind holes to meet the unique demands of each electronic device. As technology continues to advance, the evolution of interconnection methods will undoubtedly contribute to more efficient and compact electronic designs.