- 17

- Apr

Ensuring High-Quality PCB Assembly: A Comprehensive Guide by IPCB

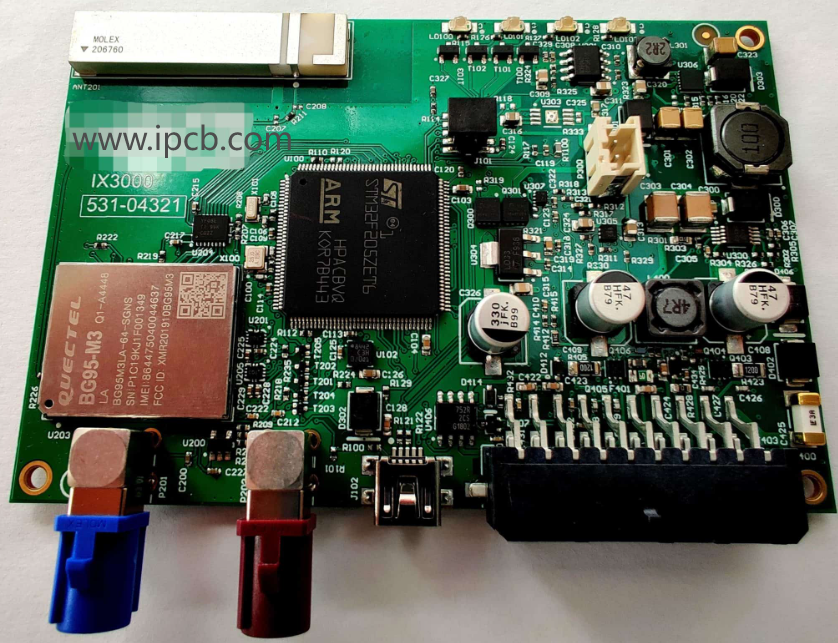

In the realm of electronic technology, printed circuit boards (PCBs) stand as the backbone of our modern devices. As demands for efficiency, durability, and traceability soar, the importance of impeccable PCB assembly and processing becomes paramount. At IPCB, we’re dedicated to unraveling the intricacies of this vital process, ensuring that each step is meticulously executed to deliver products of unmatched quality and reliability.

1. The PCB Assembly and Processing Journey

- Components Procurement and Preparation: Our journey begins with the meticulous procurement of electronic components, ranging from resistors to integrated circuits, ensuring the highest quality materials for our assemblies.

- Solder Paste Printing: Precision is key as solder paste is delicately applied to designated areas using specialized steel mesh stencils, guaranteeing accuracy in component placement.

- PCB Fabrication: Through a series of intricate processes including printing, etching, and drilling, the blueprint of our circuit designs is transformed into tangible PCBs, ready to host electronic components.

- PCB Assembly Technology: Embracing both Surface Mount Technology (SMT) and Plug-in Mount Technology (DIP), we meticulously mount components onto the PCBs, employing techniques like soldering and pasting with utmost precision.

- Welding: Employing diverse methods such as reflow soldering and wave soldering, we ensure secure connections between components and PCBs, fostering durability and stability in our assemblies.

- Cleaning Circuit Board: Post-soldering, thorough cleaning ensures the removal of any residue, while protective coatings fortify the PCBs, enhancing their longevity and resilience.

- Checking and Testing: At every juncture, stringent inspections including visual checks, AOI, X-ray inspections, and functional testing are conducted to guarantee compliance with the highest quality standards.

- Packaging and Shipping: Tailored packaging solutions ensure the safe transit of our products, safeguarding against any potential damage en route to our valued customers.

2. Quality Control and Testing

- Inspection Equipment: Leveraging cutting-edge technology including Automated Optical Inspection (AOI), X-ray Inspection Systems, and Flying Probe Testing, we leave no stone unturned in our quest for perfection.

- Inspection Methods: From manual inspections to sophisticated AOI and X-ray techniques, each method is meticulously employed to detect and rectify any imperfections, ensuring the flawless performance of our assemblies.

3. IPCB’s Quality Assurance Measures

- Quality Control: At IPCB, quality is not just a priority; it’s our ethos. Through rigorous inspections at every stage, we uphold the highest standards of quality, ensuring that only the finest products reach our customers.

- Quality Management System: Our adherence to modern quality management systems enables us to swiftly identify and address any issues, driving continuous improvement and excellence across our production processes.

- Employee Training and Development: Investing in our employees’ skills and knowledge is paramount. Through comprehensive training programs, we empower our workforce to execute their tasks with precision and diligence, ensuring adherence to quality standards.

- Quality Certifications: With certifications including ISO 9001, IPC-A-600, IPC-A-610, ROHS compliance, and IATF 16949, we demonstrate our unwavering commitment to quality and regulatory compliance.

4. Development Goals

- Automation Integration: As electronic production grows increasingly complex, IPCB is committed to integrating automation into our assembly and testing processes, optimizing efficiency and quality across the board.

- Real-Time Monitoring and Testing: By implementing real-time testing and monitoring systems, we strive to ensure that each step of the PCB assembly process adheres rigorously to established standards, guaranteeing unparalleled accuracy and stability in our products.

In conclusion, at IPCB, our dedication to excellence permeates every facet of our PCB assembly and processing. Through meticulous attention to detail, cutting-edge technology, and unwavering commitment to quality, we stand poised to meet and exceed the evolving needs of our customers in the ever-changing landscape of electronic technology.