- 23

- Jun

Shelf life and cost of PCBA

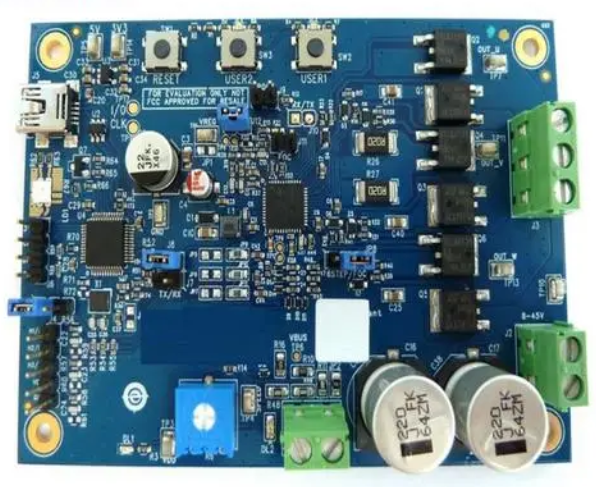

PCBA is the abbreviation of printed circuit board assembly in English, that is to say, the empty PCB passes through SMT loading or the whole process of dip plug-in, which is called PCBA for short This is a commonly used writing method in China, while the standard writing method in Europe and America is pcb’a with “‘”, which is called the official idiom. Here is how long PCBA processing products can be stored.

How long can PCBA processed products be stored。

PCBA refers to a circuit board with various components welded on its surface. People often pay attention to its reliability of long-time and high-frequency operation, and sometimes need to know its shelf life. Generally, the storage life of PCBA processed products is 2-10 years, which is mainly affected by the following factors:

1. Environment

Humid and dusty environment is obviously not conducive to the preservation of PCBA. These factors will accelerate the oxidation and dirt of PCBA and shorten the shelf life of PCBA. Generally, it is recommended to store PCBA in a dry, dust-free space with a constant temperature of 25 ℃.

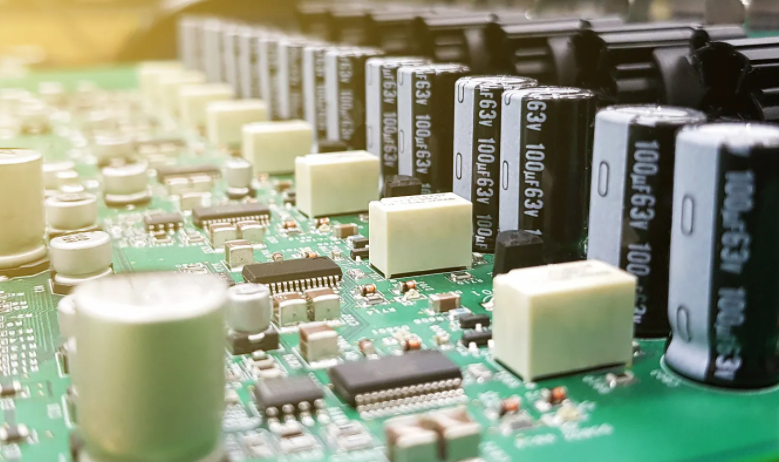

2. Reliability of components

The reliability of components and parts on different PCBAs also largely determines the shelf life of PCBA. Components and parts with high quality materials and processes have the ability to resist harsh environments, with a wider range of capabilities and stronger oxidation resistance, which also provides guarantee for the stability of PCBA.

3. Material and surface treatment process of circuit board

The material of circuit board itself is not easily affected by the environment, but its surface treatment process is greatly affected by air oxidation. Good surface treatment can prolong the shelf life of PCBA.

4. PCBA board running load

PCBA operation load is the most important factor for its storage life. The operation with high frequency and high load will have a continuous high impact on the circuit board lines and components, which will be easier to oxidize under the influence of heating, resulting in short circuit and open circuit during long-term operation. Therefore, the operating parameters of the PCBA board should be within the middle range of the components and avoid being near the peak value, which can effectively protect the PCBA and extend its storage life.

The shelf life of PCBA processed products is a comprehensive work, which needs to follow the scientific design specifications, manufacturing process specifications and operation specifications, so as to maximize the shelf life.

The above is the specifications and factors that can be saved for PCBA processing products. I hope it can help you.

Now there are so many electronic equipment, as long as the products that can be used need PCB, many manufacturers of electronic products do not know how to charge for PCBA processing. PCBA processing costs are composed of those.

PCBA patch processing cost composition

1. PCB fee (if you provide it yourself, it will not be charged);

2. component purchase fee (if you also provide this by yourself, it is also free of charge);

3. SMT processing fee (SMD chip +dip post welding);

4. PCBA test fee and assembly fee.

Cost calculation of PCBA patch processing

1、 PCB board fee

If you want to find a PCBA processor to help you process, you need to provide PCB files and BOM list. The PCBA processor will help you make PCB bare boards according to your PCB files. At this time, the first part of the cost, PCB board fee, will be incurred. The cost of PCB board depends on the process difficulty of the board. For example, the prices of 4-layer board, 8-layer board, aluminum substrate and carbon ink board are different. Of course, you can also find your own PCBA board factory for processing. The price is certainly not so cheap. After all, there must be a discount for others’ long-term cooperation. Please feel free to be a local tyrant.

2、 Component purchase cost

PCBA patch processing part II cost, component purchase cost. The processing manufacturer purchases the components and parts you need according to the BOM. When purchasing components and parts, due to disk loading such as resistors and capacitors and SMT chip loss (such as jumping the wrong board, not clearing the coil tape in time, etc.), about 5% of the material loss should be covered; Manufacturers have long-term cooperation with component manufacturers, so the price will be lower.

3、 SMT processing fee (SMD chip +dip post welding)

When calculating the SMT processing fee, you should first see how large your processing batch is. If it is greater than 2000pic, there is no need to charge the engineering fee, otherwise there will be an additional engineering fee. Next, calculate the number of points multiplied by the unit price of points. The unit price of patch points is between 0.01-0.015 yuan. The number of points is calculated according to two pins of SMT patch material and one pin of dip plug-in. Multiply the two. Refinement can be divided into:

1.0402 element is calculated as 0.015 per dot * currency 0603-1206 components are calculated by 0.015 per point * currency

2. one pin of plug-in material is a point; It is calculated as 0.015 per point * currency.

3. four pins of slot type are one point; It is calculated as 0.015 per point * currency.

4. common IC, 4 pins are 1 point; It is calculated as 0.015 per point * currency.

5. dense pin IC, two pins are one point; It is calculated as 0.015 per point * currency.

6. two BGA legs are one point; It is calculated as 0.015 per point * currency.

7. machine pasted bulk materials shall be calculated by doubling the volume of components.

8. the additional fee is calculated as 20 yuan * per hour

9. the quotation does not include the test fee, transportation fee, tax, etc.

4、 PCBA test fee and assembly fee

The PCBA test fee is generally calculated as 2 yuan per plate, plus the PCBA assembly and packaging fee, which is generally 0.8 yuan per plate. This is the fourth part of the fee.

Add up the above four parts of the cost, which is the PCBA patch processing cost.

The above is how to charge for PCBA patch processing? The introduction to the composition of PCBA patch processing costs, I hope it can help you, and I want to know more about PCBA processing information.