- 18

- Sep

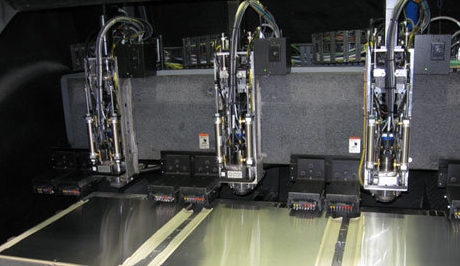

Drilling holes for printed circuit boards

Drilling holes for printed circuit boards

свідравальны станок

Good corrosion друкаваная плата, just a piece of semi-finished products, must go through drilling brush flux and other processes. In order to improve the reliability of printed circuit boards used in some equipment, silver plating is often required.

The hole of друкаваная плата determines the position of welding components and is directly related to the quality of installation, so it is required to drill holes according to the size marked on the drawing. Holes must be drilled right, can not have skewed phenomenon. In particular, the jacks of various transformers, filters and variable capacitors shall not be tilted, otherwise the components shall be installed askew, and even cannot be installed.

When drilling, in order to make the holes drilled smooth, no burr, in addition to the drill to grind fast, all component holes under 2mm in diameter, to use high-speed drilling, conditional, as far as possible in 4000r/min above. If the speed is too low, the holes drilled out have serious burrs. But for the diameter of the hole above 3mm, the speed should be lowered accordingly. Below amateur condition, borehole uses hand electric drill, bench drill normally, also can use hand shake drill.