- 06

- Oct

How is the structure of FPC flexible circuit board designed

How is the structure of Placă de circuit flexibil FPC proiectat

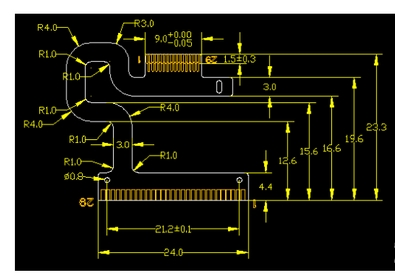

FPC flexible circuit board is a fragile part. If it is not designed properly, it is easy to break. For the structure, we are most concerned about the appearance of FPC. On the premise of ensuring the realization of function, it should be as narrow and thin as possible, otherwise it is easy to scratch and break with the shell at the FPC through hole of mobile phone B / C. When designing the appearance of FPC soft board, pay attention to the radius of the corner. Generally, the minimum radius of the inner corner is R1 and the radius of the outer corner is R3 or R4. The following figure shows our dragon FPC drawings, which you can refer to:

The width of FPC design is related to pin line width, line spacing and pin number. If there are more pins, it will naturally be widened, or double-sided board can be used to replace single panel to reduce the width. Of course, the thickness is bound to increase. As for the length of FPC, because FPC has good flexibility and good bending, there can be allowance for the length, so it is not necessary to calculate it completely. In addition, it is very important that when designing the appearance of FPC, we pay attention to the clearance with B / C parts and through holes. When the wall thickness and strength of B / C parts have been met, we try to leave more space for FPC soft board. The design of this place is the top priority of our design.

Finally, I hope you can use the sheet metal module instead of the part solid module when designing the FPC soft board with Pro / E, because in the sheet metal module, the FPC flexible circuit board can make the FPC shape closest to the actual situation. It is easy to bend and flatten, and easy to modify, and can truly simulate the theoretical real position of the FPC flexible circuit board in the via. Note: the contents involved in the above design are only for the structural design. Some hardware related indicators are not mentioned here. When doing the design, we should also cooperate with the hardware to communicate with the manufacturer to make the most perfect design.