- 04

- Oct

Why brush three proofing paint for PCB circuit board?

Why brush three proofing paint for PCB circuit board?

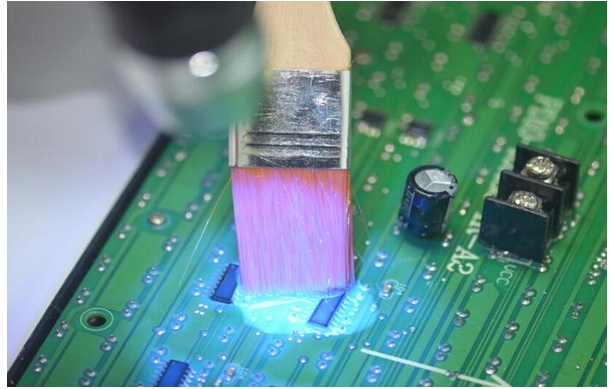

Three proofing paint is a specially formulated coating, which is used to protect PCB and its related equipment from the erosion of bad environment. The three proofing paint has good high and low temperature resistance. After curing, it will form a transparent protective film to protect the circuit from damage under the conditions of chemical substances, moisture, salt fog, humidity and high temperature.

Under these conditions, the circuit board may be corroded, mold growth and short circuit. The three anti paint has superior properties such as insulation, moisture-proof, anti leakage, dust-proof, anti-corrosion, anti-aging, anti mold, anti part loosening and insulation corona resistance. Among them, moisture is the most common and destructive factor to PCB. Too much moisture will greatly reduce the insulation resistance between conductors, accelerate high-speed decomposition, reduce Q value and corrode conductors. We often see that the metallic part of PCB board is green, which is caused by the chemical reaction of copper, water vapor and oxygen, which is not coated with three proofing paint.

When the three proofing paint is coated on the PCB circuit board and components, when it may be affected by the adverse factors of the operating environment, the deterioration of electronic operating performance can be reduced or eliminated. If the coating can maintain its function for a satisfactory period of time, such as longer than the service life of the product, it can be regarded as having achieved its coating purpose