- 04

- Oct

Basic material of circuit board

Basic Material of PCB

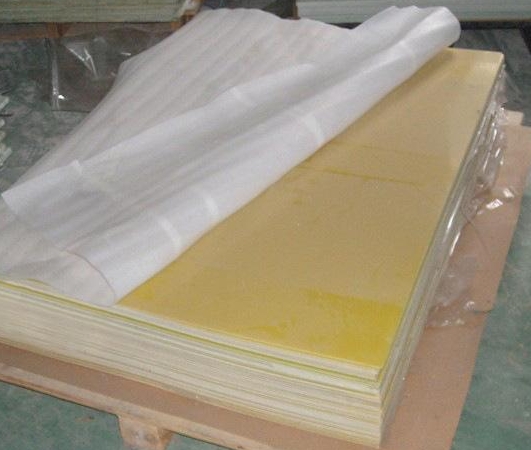

How are common copper clad laminates made? Generally, copper-clad laminate is made of reinforced materials (glass fiber cloth, glass felt, impregnated fiber paper, etc.), impregnated with resin adhesive, dried, cut and stacked into blank, then covered with copper foil, steel plate as mold, and formed at high temperature and high pressure in hot press

Clad laminates

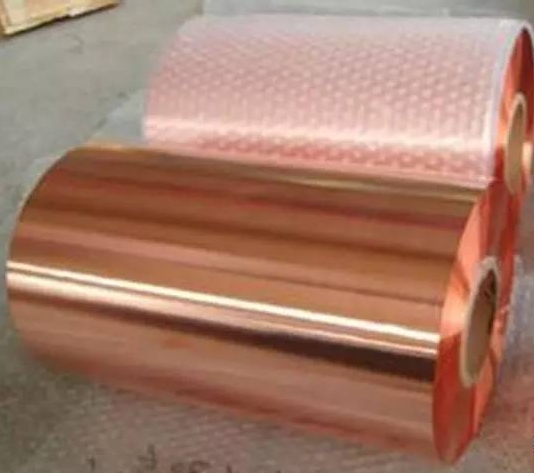

What kinds of copper clad laminates can be divided into according to the rigidity and flexibility of the plate and the different reinforcing materials? According to the rigidity and flexibility of the plate, it can be divided into rigid copper clad laminate and flexible copper clad laminate. According to different reinforcing materials, they can be divided into four categories: paper based, glass cloth based, composite based (CEM series, etc.) and special material based (ceramic, metal based, etc.). 3. Briefly describe the significance of the national standard GB / t4721-92.

Copper

The first letter of the product model, C, means copper-clad foil.

The second and third letters indicate the resin used for the substrate;

The fourth and fifth letters indicate the reinforcing material used for the base material; At the end of the letter, two digits are connected by a short horizontal line to represent the product number of the same type but different performance.

4. What do the following abbreviations mean? JIS, ASTM, NEMA, mil, IPC, ANSI, IEC, BS < br / > JIS Japanese Industrial Standard < br / > ASTM American Society for testing and materials standard< Br / > NEMA American Manufacturing Association standards < br / > mil American military standards < br / > IPC American circuit interconnection and Packaging Association standards < br / > ANSI American National Standards Association standards UL American Insurance Association laboratory standards < br / > IEC International Electrotechnical Commission standards < br / > BS British Standards Association standards DIN German Standards Association standards VDE German electrical standards CSA Canadian Standards Association standards as Australia Standards Institute standards

5. Briefly describe UL standards and quality and safety certification bodies? UL is the beginning of Underwriters Laboratories. UL has issued about 6000 safety standard documents. Standards relating to copper clad laminates are contained in u1746.

6. What are the two main categories of copper foil according to different preparation methods? What are they called in IPC standards? It can be divided into calendered copper foil and electrolytic copper foil. They are called class W and class E respectively in IPC standards

7. Briefly describe the performance characteristics and preparation methods of calendered copper foil and electrolytic copper foil. Calendered copper foil is made by repeatedly rolling copper plate. Like electrolytic copper foil, it needs coarsening treatment after the production of wool foil. The bending resistance and elastic coefficient of calendered copper foil are higher than that of electrolytic copper foil, the copper purity is higher than that of electrolytic copper foil, and the rough surface is smoother than that of electrolytic copper foil.

8. Briefly describe various technical properties of electrolytic copper foil and its influence on the properties of copper clad laminate? A. Thickness. > B. Appearance. C. Tensile strength and elongation. The low elongation and tensile strength at high temperature will lead to the change of dimensional stability and flatness of semi-conductor, the decline of the quality of metallized holes in PCB and the fracture of copper foil when using PCB. D. Peel strength. The peel strength of LP, VLP and SLP copper foils with low Coarseness on printed boards and multilayer boards with fine lines is better than that of ordinary copper foils (STD and HTZ). E. Folding resistance. The longitudinal and transverse difference of electrolytic copper foil is slightly higher in the transverse direction than in the longitudinal direction. F. Surface roughness. G. Etchability. > H. High temperature oxidation resistance. In addition to the above eight main technical properties of copper foil, there are plasticity of copper foil, adhesion of UV ink, quality of copper foil, electroplating coefficient and color of copper foil.

9. Briefly describe the performance of glass fiber cloth? The basic performance items include: warp and weft type, weaving density (number of warp and weft yarns), thickness, weight per unit area, width and breaking strength (tensile strength).

10. According to NEMA standard, generally paper-based copper-clad laminates are divided according to their functions. What are the common ones? Common varieties include: XPC, xxxpc, FR-1 (xpc-fr), FR-2 (xxxpc-fr), fr-3, etc.

11. Compare general paper-based copper-clad laminate with epoxy glass cloth based copper-clad laminate? A product made of wood pulp paper or glass fiber cloth as reinforcement, impregnated with resin, covered with copper foil on one or both sides and hot pressed.