- 04

- Oct

Boitsebiso ba mantlha ba boto ea potoloho

Boitsebiso ba Motheo ba PCB

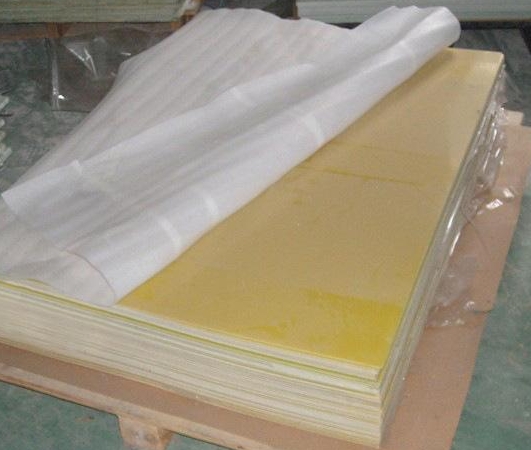

Li-laminate tse tloaelehileng tsa koporo li entsoe joang? Ka kakaretso, laminate e koahetsoeng ka koporo e entsoe ka lisebelisoa tse matlafalitsoeng (lesela la khalase ea fiber, khalase e utloiloe, pampiri ea fiber e kentsoeng, jj.) , ‘Me e thehiloe ka mocheso o phahameng le khatello e phahameng mochineng o chesang

Apesa laminates

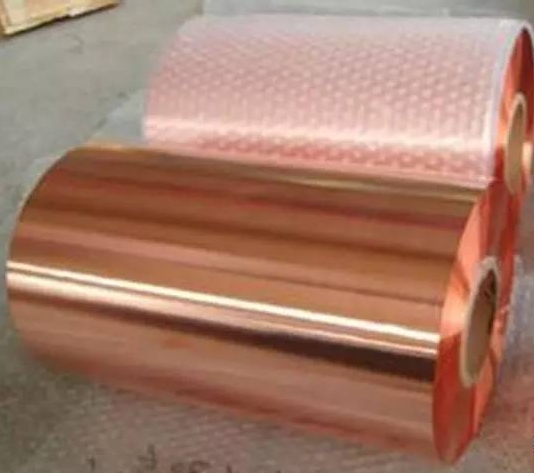

Ke mefuta efe ea laminate tse koahetsoeng ka koporo e ka aroloang ho latela ho tenyetseha le ho fetoha ha poleiti le thepa e fapaneng e matlafatsang? Ho latela ho tenyetseha le ho tenyetseha ha poleiti, e ka aroloa ka thata koporo e apereng laminate le tenyetsehang koporo e apereng laminate. Ho latela lisebelisoa tse fapaneng tse matlafatsang, li ka aroloa ka mekhahlelo e mene: pampiri e thehiloeng, lesela la khalase le entsoe ka likarolo tse ngata (CEM series, jj.) Le thepa e ikhethileng e thehiloeng (ceramic, tšepe based, jj.). 3. Hlalosa ka bokhutšoanyane bohlokoa ba tekanyetso ea naha ea GB / t4721-92.

koporo

Lengolo la pele la mofuta oa sehlahisoa, C, le bolela foil e koahetsoeng ka koporo.

Litlhaku tsa bobeli le tsa boraro li bonts’a lehoakhoa le sebelisitsoeng bakeng sa substrate;

Litlhaku tsa bone le tsa bohlano li supa lisebelisoa tse matlafatsang tse sebelisitsoeng bakeng sa thepa ea motheo; Qetellong ea lengolo, linomoro tse peli li hokahane ka mola o mokhutšoane o emeng ho emela palo ea sehlahisoa sa mofuta o le mong empa ts’ebetso e fapaneng.

4. Dikhutsufatso tse latelang di bolelang? JIS, ASTM, NEMA, mil, IPC, ANSI, IEC, BS litekanyetso tsa sesole <br /> IPC American potoloho ea khokahano le liphutheloana tsa Mokhatlo oa Ho Paka <br /> Litekanyetso tsa ANSI American National Standards Association litekanyetso tsa UL American Insurance Association litekanyetso tsa laboratori <br /> Litekanyetso tsa IEC International Electrotechnical Commission Litekanyetso tsa Mokhatlo oa Melao ea Boemo ea VDE Litekanyetso tsa motlakase tsa Jeremane CSA litekanyetso tsa Mokhatlo oa litekanyetso tsa Canada joalo ka litekanyetso tsa Australia

5. Hlalosa ka bokhutšoanyane litekanyetso tsa UL le mekhatlo ea netefatso ea boleng le polokeho? UL ke qalo ea Underwriters Laboratories. UL e ntšitse litokomane tse ka bang 6000 tsa maemo a polokeho. Litekanyetso tse amanang le laminate tse koahetsoeng ka koporo li fumaneha ho u1746.

6. Ke mefuta efe e ‘meli ea mantlha ea koporo ea koporo ho latela mekhoa e fapaneng ea boitokiso? Li bitsoa eng maemong a IPC? E ka arotsoe ka foil ea koporo ea calendered le foil ea elektrolytic ea koporo. Li bitsoa sehlopha sa W le sehlopha sa E ka tatellano ho latela maemo a IPC

7. Hlalosa ka bokhutšoanyane litšobotsi tsa ts’ebetso le mekhoa ea boitokisetso ea cilie ea koporo ea khalendara le foil ea koporo ea electrolytic. K’halendara ea koporo e entsoe ka ho phethola poleiti ea koporo khafetsa. Joalo ka foil ea koporo ea electrolytic, e hloka kalafo e matlafatsang kamora tlhahiso ea boea ba boea. Ho hanyetsa le ho kobeha ha coefficient ea koporo ea calendered ho phahame ho feta ea koporo ea koporo ea electrolytic, bohloeki ba koporo bo phahame ho feta ba koporo ea koporo ea electrolytic, ‘me bokaholimo bo boreleli bo boreleli ho feta ba koporo ea koporo ea elektrolytic.

8. Hlalosa ka bokhutšoanyane litšobotsi tse fapaneng tsa tekheniki ea koporo ea koporo ea elektrolytic le tšusumetso ea eona ho thepa ea koporo e koahetsoeng ka laminate? A. Botenya. > B. Ponahalo. C. Tensile matla le bolelele. Bolelele bo tlase le matla a tensile mocheso o phahameng li tla lebisa phetohong ea botsitso ba mahlakore a mabeli le boreleli ba semi conductor, ho theoha ha boleng ba masoba a metallized ho PCB le ho robeha ha foil ea koporo ha o sebelisa PCB. D. Matla a letlalo. Matla a likhase a LP, VLP le SLP a koporo a nang le Coarseness e tlase ho liboto tse hatisitsoeng le liboto tsa multilayer tse nang le mela e metle li betere ho feta tsa likopi tse tloaelehileng tsa koporo (STD le HTZ). E. Ho hanyetsa. Phapang ea longitudinal le transverse ea foil ea elektrolytic ea koporo e phahame hanyane ka lehlakoreng le fetang ho leba ntlheng ea longitudinal. F. Bophahamo ba bokaholimo. G. Etchability. > H. Ho hanyetsa mocheso o phahameng oa mocheso. Ntle le likarolo tse robeli tse kaholimo tsa theknoloji ea koporo ea koporo, ho na le polasetiki ea koporo ea koporo, khokahano ea enke ea UV, boleng ba koporo ea koporo, coefficient ea electroplating le ‘mala oa koporo ea koporo.

9. Hlalosa hakhutšoanyane ts’ebetso ea lesela la khalase ea khalase? Lintho tsa mantlha tsa ts’ebetso li kenyelletsa: mofuta o lohiloeng le o lohiloeng, palo ea ho loha (palo ea likhoele le likhoele), botenya, boima sebakeng ka seng, bophara le matla a ho roba (matla a tensile).

10. Ho ea ka maemo a NEMA, ka kakaretso laminate tse koahetsoeng ka koporo li arotsoe ho latela mesebetsi ea bona. Tse tloaelehileng ke life? Mefuta e tloaelehileng e kenyelletsa: XPC, xxxpc, FR-1 (xpc-fr), FR-2 (xxxpc-fr), fr-3, jj.

11. Bapisa laminate e koahetsoeng ka koporo e koahetsoeng ka koporo le lesela la khalase la epoxy le entsoe ka laminate ea koporo? Sehlahisoa se entsoeng ka pampiri ea lehong kapa khalase ea fiber e le matlafatso, e kentsoeng ka lehoakhoa, e koahetsoeng ka koporo ea koporo ka lehlakore le leng kapa mahlakore ka bobeli mme e hatisitsoe ka chesang.