- 04

- Oct

Cov khoom siv yooj yim ntawm Circuit Board

Cov khoom siv yooj yim ntawm PCB

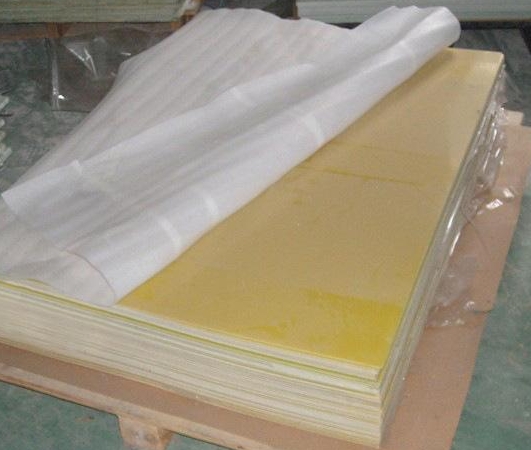

Yuav ua li cas cov tooj liab clad laminates ua? Feem ntau, tooj liab-clad laminate yog ua los ntawm cov ntaub ntawv txhawb ntxiv (iav ntaub ntaub, iav zoo li, cov ntawv tsis muaj ntaub qhwv, thiab lwm yam), impregnated nrog cov nplaum nplaum, qhuav, txiav thiab muab tso rau hauv qhov khoob, tom qab ntawd npog nrog tooj liab ntawv ci, phaj hlau ua pwm , thiab tsim ntawm qhov kub thiab txias siab hauv kub nias

Laminated iav

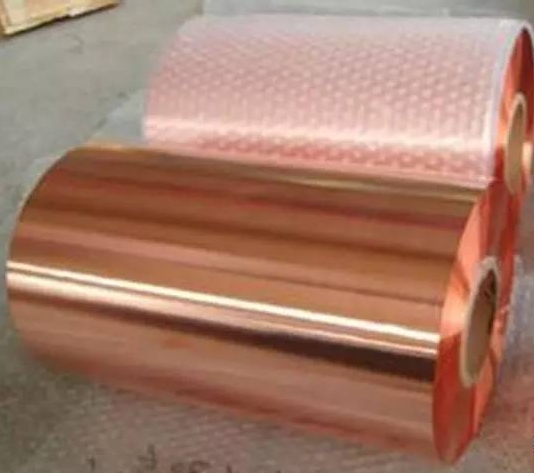

Hom tooj liab clad laminates twg tuaj yeem faib ua raws qhov nruj thiab hloov pauv ntawm cov phaj thiab cov khoom sib txawv txhawb ntxiv? Raws li qhov nruj thiab yooj ntawm lub phaj, nws tuaj yeem muab faib ua txhav tooj liab txhav laminate thiab hloov pauv tooj liab clad laminate. Raws li cov ntaub ntawv txhawb nqa sib txawv, lawv tuaj yeem faib ua plaub pawg: ntawv raws, iav daim ntaub raws, sib xyaw raws (CEM series, thiab lwm yam) thiab cov khoom tshwj xeeb raws li (ceramic, hlau raws, thiab lwm yam). 3. Piav qhia luv luv qhov tseem ceeb ntawm lub teb chaws tus qauv GB / t4721-92.

Tooj

Thawj tsab ntawv ntawm cov qauv khoom, C, txhais tau tias yog tooj liab-clad ntawv ci.

Cov ntawv thib ob thiab thib peb qhia txog cov tshuaj uas siv rau cov khoom siv;

Cov ntawv plaub thiab thib tsib qhia txog cov khoom txhawb ntxiv uas siv rau cov khoom siv hauv paus; Qhov kawg ntawm tsab ntawv, ob tus lej txuas nrog kab ntawv kab rov tav luv los sawv cev rau cov lej khoom ntawm tib hom tab sis kev ua haujlwm sib txawv.

4. Cov ntawv luv hauv qab no txhais li cas? JIS, ASTM, NEMA, mil, IPC, ANSI, IEC, BS <br /> JIS Japanese Industrial Standard <br /> ASTM American Society rau kev sim thiab cov khoom siv txheem <Br /> NEMA American Manufacturing Association tus qauv <br /> mil American cov qauv kev ua tub rog <br /> IPC Asmeskas kev sib txuas ntawm Circuit Circuit thiab Ntim Association tus qauv <br /> ANSI American National Standards Association tus qauv UL American Insurance Association lub chaw kuaj sim <br /> IEC International Electrotechnical Commission cov qauv <br /> BS British Standards Association standard DIN German Cov Koom Haum Cov Qauv VDE Cov qauv siv hluav taws xob German CSA Canadian Standards Association cov qauv raws li Australia Cov Qauv Lub Koom Haum cov qauv

5. Piav qhia luv luv txog UL cov qauv thiab lub cev thiab daim ntawv pov thawj kev nyab xeeb? UL yog qhov pib ntawm Underwriters Laboratories. UL tau tshaj tawm txog 6000 daim ntawv pov thawj kev nyab xeeb. Cov qauv hais txog tooj liab clad laminates muaj nyob hauv u1746.

6. Dab tsi yog ob pawg tseem ceeb ntawm cov ntawv ci tooj liab raws li kev npaj sib txawv? Lawv hu dab tsi hauv IPC tus qauv? Nws tuaj yeem faib ua cov ntawv ci tooj liab thiab cov ntawv tooj liab electrolytic. Lawv raug hu ua chav kawm W thiab chav E feem hauv IPC cov qauv

7. Piav qhia luv luv txog cov yam ntxwv ua haujlwm thiab cov txheej txheem npaj ntawm daim ntawv tooj liab tooj liab thiab cov ntawv tooj liab electrolytic. Cov ntawv ci tooj liab tau ua los ntawm kev rov ua dua tooj liab phaj. Zoo li cov ntawv ci tooj liab electrolytic, nws xav tau kev kho kom zoo tom qab tsim cov ntawv ci. Kev khoov thiab ua kom muaj zog coefficient ntawm cov ntawv ci tooj liab yog siab dua li cov ntawv ci tooj liab, cov tooj liab huv yog siab dua li cov ntawv ci tooj liab electrolytic, thiab qhov ntxhib yog du dua li cov ntawv ci tooj liab electrolytic.

8. Piav qhia luv luv txog ntau yam txheej txheem txheej txheem ntawm cov ntawv tooj liab tooj liab thiab nws qhov cuam tshuam rau cov yam ntxwv ntawm tooj liab clad laminate? A. Thickness. > B. Qhov tshwm sim. C. Tensile zog thiab elongation. Qhov qis qis thiab lub zog tensile ntawm qhov kub siab yuav ua rau kev hloov pauv ntawm kev ruaj ntseg thiab kev tiaj tus ntawm tus neeg ua haujlwm ib nrab, kev poob qis ntawm qhov ua tau zoo ntawm cov hlau hauv PCB thiab qhov tawg ntawm tooj liab ntawv thaum siv PCB. D. Tev lub zog. Tev lub zog ntawm LP, VLP thiab SLP tooj liab foils nrog qis Coarseness ntawm cov ntawv luam tawm thiab cov laug cam ntau txheej nrog cov kab zoo yog qhov zoo dua li cov tooj liab tooj liab (STD thiab HTZ). E. Folding kuj. Qhov ntev thiab qhov sib txawv ntawm cov ntawv tooj liab electrolytic yog siab dua me ntsis hauv qhov kev hloov pauv dua li qhov kev coj ua ntev. F. Kev ntxhib los mos. G. Etchability. > H. Kub kub oxidation kuj. Ntxiv rau yim qhov tseem ceeb tshaj plaws ntawm cov khoom siv tooj liab, muaj cov yas yas ntawm cov ntawv ci tooj liab, nplaum ntawm UV number case, zoo ntawm cov ntawv ci tooj liab, electroplating coefficient thiab xim ntawm cov ntawv ci tooj liab.

9. Piav qhia luv luv qhov ua tau zoo ntawm daim ntaub iav iav? Cov khoom ua tau yooj yim suav nrog: hom warp thiab weft, weaving ntom (tus xov tooj ntawm warp thiab weft yarns), tuab, hnyav ib cheeb tsam ib cheeb tsam, dav thiab tawg zog (lub zog tensile).

10. Raws li NEMA tus qauv, feem ntau siv cov ntawv raws tooj liab-clad laminates tau faib raws li lawv lub luag haujlwm. Cov uas ib txwm muaj yog dab tsi? Ntau yam muaj xws li: XPC, xxxpc, FR-1 (xpc-fr), FR-2 (xxxpc-fr), fr-3, thiab lwm yam.

11. Sib piv daim ntawv-raws tooj liab-clad laminate nrog epoxy iav ntaub raws tooj liab-clad laminate? Cov khoom lag luam ua los ntawm cov ntoo pulp ntawv lossis iav iav daim ntaub ua qhov txhawb nqa, ua kom tsis muaj xim nrog, npog nrog cov ntawv ci tooj liab ntawm ib lossis ob sab thiab kub nias.