- 26

- Sep

What are the technical terms for each layer of PCB?

The design of printed PCB board starts from the determination of the size of the board. The size of printed PCB board is limited by the size of the chassis shell, so it is appropriate to place the printed PCB board into the shell. Secondly, the connection mode between the printed PCB board and external components (mainly potentiometers, sockets or other printed PCB board) should be considered. The printed PCB board is usually connected to external components by plastic wires or metal isolation wires. But it is sometimes designed as a socket. That is, to install a plug-in PRINTED PCB in the equipment, the circuit board should leave a contact position to act as a socket.

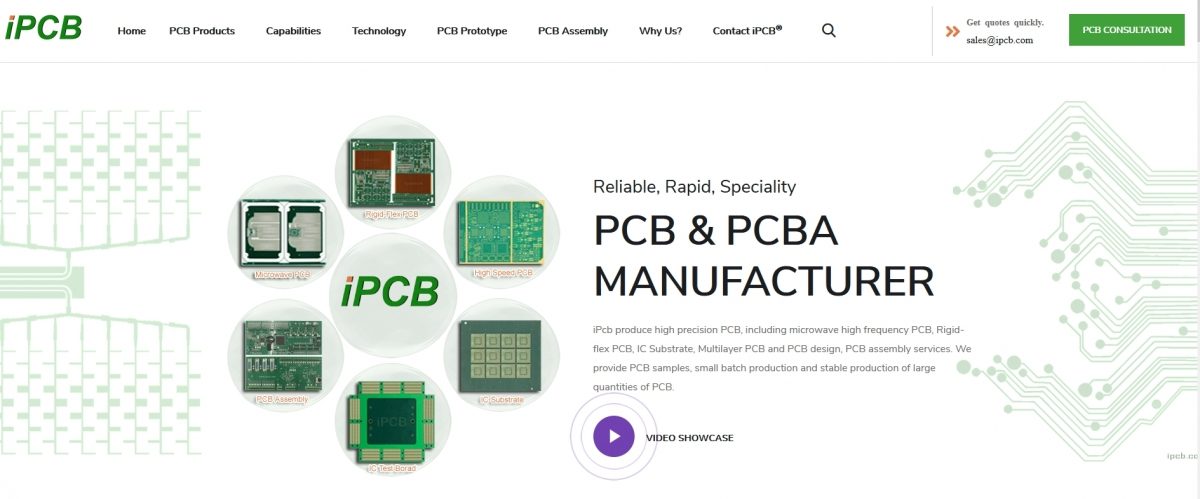

The following IPCB board manufacturer in Shenzhen to introduce the PCB board layers of professional terms:

Drilling layer: The drilling layer provides drilling information during the manufacturing process of the circuit board (such as pads, holes need to be drilled).

Signal layer: The signal layer is mainly used to lay out the wires on the circuit board.

Solder resist: apply a coating, such as anti-solder paint, to all parts other than the pad to prevent tin from being applied to these parts. The solder resist layer is used to match pads during the design process and is automatically generated.

Solder paste protection layer, S-MD patch layer: It is similar to the solder resist layer, except for the pad corresponding to the surface sticking element during machine welding.

Forbidden wiring layer: Used to define the area on the circuit board where components and wiring can be efficiently placed. Draw a closed area on this layer as an effective area for wiring, outside of which automatic layout and wiring is not possible.

Screen printing layer: The screen printing layer is mainly used to place printed information, such as the outline and annotation of components, various annotation characters, etc. Generally, all kinds of annotation characters are in the top screen printing layer, the bottom screen printing layer can be closed.

Internal power supply/ground layer: This type of layer is only used for multi-layer boards, mainly for laying power and ground cables. We call them double, four, or six boards, generally referring to the number of signal layers and internal power/grounding layers.

Mechanical layer: this layer is used to set the circuit board dimensions, data marks, alignment marks, assembly instructions and other mechanical information. This information varies depending on the requirements of the design company or PCB manufacturer. In addition, the mechanical layer can be attached to other layers together with the output display.

Multilayer: the pads and ChuangTou holes on the circuit board to ChuangTou the entire circuit board, with different conductive graphics layer to establish electrical connections, so the system specially set up an abstract layer – multilayer. Generally, pads and holes are set on multiple layers, and if this layer is closed, pads and holes will not be shown.