- 06

- Oct

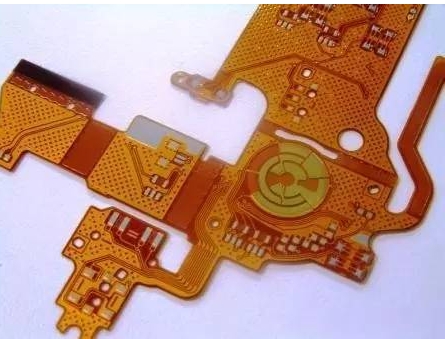

How to solve the glue overflow of FPC flexible circuit board

How to solve the glue overflow of FPC çevik dövrə kartı

Glue overflow is a common quality abnormality in the pressing process of FPC flexible circuit board. Glue overflow refers to the glue system flowing in coverlay due to the increase of temperature in the pressing process, resulting in glue stains similar to export series on the pad of FPC flexible circuit board. There are many reasons for FPC flexible circuit board glue overflow, so we should put forward different solutions according to the specific situation.

1. Glue overflow is caused by coverlay manufacturing process

Then, FPC flexible circuit board manufacturers should strictly inspect the incoming materials. If the glue overflow exceeds the standard in the incoming sampling inspection, contact the supplier to return and replace the goods, otherwise it is difficult to control the glue overflow in the production process.

2. Glue overflow is caused by storage environment

FPC FPC manufacturers had better establish a special freezer to store the protective film. If the CL adhesive system is affected by moisture due to the storage conditions failing to meet the requirements, the CL can be pre baked at low temperature, which can greatly improve the glue overflow of CL. In addition, CL not used up on the same day shall be put back into the freezer for storage in time.

3. Local glue overflow caused by independent small pad position

This phenomenon is the most common quality abnormality encountered by most FPC flexible circuit board manufacturers in China. If the process parameters are changed simply to solve the glue overflow, it will bring new problems such as bubbles or insufficient peel strength, so the process parameters can only be adjusted reasonably.

4. Glue overflow caused by operation mode

During the false connection of FPC flexible circuit board, employees need to accurately align, correct the alignment fixture, and increase the inspection strength of alignment to avoid glue overflow due to inaccurate alignment. At the same time, do a good job in “5S” during crimping and false connection. Before alignment, check whether the protective film CL is polluted and whether there are burrs.

5. Glue overflow caused by FPC flexible circuit board factory process

If the fast press is used for pressing, properly extending the preloading time, reducing the pressure, reducing the temperature and reducing the pressing time are conducive to reducing the glue overflow. If the pressure of the press is uneven, you can use induction paper to test whether the pressure of the press is uniform. You can contact the fast press supplier to debug the machine and equipment.