- 22

- Sep

Indlela ukuphucula ukuthembeka thermal of PCB?

Ungakuphucula njani ukuthembeka kwe-thermal ye- IPCB

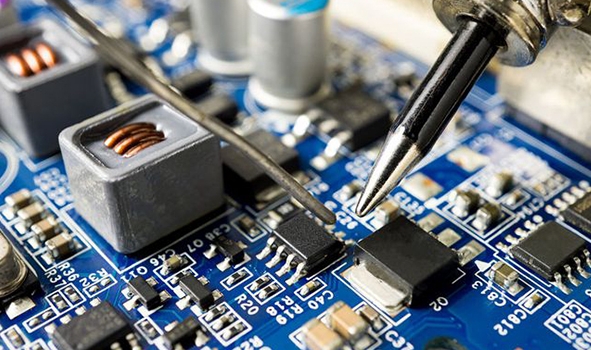

Ngokubanzi, ukuhanjiswa kwefoyile yobhedu kwi PCB inzima kakhulu kwaye kunzima ukuyilungisa ngokuchanekileyo. Ke ngoko, xa umodareyitha, kubalulekile ukwenza ubume beentambo kwaye uzame ukwenza imodeli ye-ANSYS kufutshane nebhodi yesekethe eyiyo. Izinto ze-elektroniki kwibhodi yesekethe nazo zinokulingiswa ngokwenziwa kwemodeli eyenziwe lula, enje ngeetyhubhu ze-MOS, iibhloko zesekethe ezihlanganisiweyo, njl.

Uhlalutyo olushushu kwi-chip processing lunokunceda abaqulunqi baqwalasele ukusebenza kombane kwezinto Ibhodi yesekethe PCB nokuba izinto okanye ibhodi yesekethe iya kutsha ngenxa yeqondo lobushushu eliphezulu. Uhlalutyo olulula lwe-thermal lubala kuphela iqondo lobushushu bebhodi yesekethe, kwaye eyona inzima kufuneka iseke imodeli yexeshana yezixhobo zombane ezineebhodi zesekethe ezininzi. Ukuchaneka kohlalutyo lobushushu ekugqibeleni kuxhomekeke kukuchaneka kokusetyenziswa kwamandla kwecandelo lokubonelela ngabaqulunqi bebhodi yesekethe.

Kwizicelo ezininzi, ubunzima kunye nobukhulu bomzimba kubaluleke kakhulu. Ukuba ukusetyenziswa kwamandla kwamacandelo kuncinci kakhulu, imeko yokhuseleko yoyilo inokuba phezulu kakhulu, ukuze uyilo lwebhodi yesekethe yamkele ixabiso lokusetyenziswa kwamandla elingahambelaniyo nelona okanye lilondoloze kakhulu njengesiseko sohlalutyo lobushushu. Ngokuchasene noko (kwaye ngakumbi nzulu ngaxeshanye), uyilo lokhuselo lwe-thermal lusezantsi kakhulu, Oko kukuthi, ubushushu bobuchwephesha bobuchwephesha buphezulu kunokuba bexelwe kwangaphambili ngabahlalutyi. Iingxaki ezinjalo zihlala zisonjululwa ngokongeza izixhobo zokuhambisa ubushushu okanye iifeni ukupholisa ibhodi yesekethe. Ezi zincedisi zangaphandle zonyusa iindleko kwaye zandisa ixesha lokuvelisa. Ukongeza abalandeli kuyilo kuya kuzisa izinto ezingazinzanga ekuthembekeni. Ke ngoko, ibhodi yesekethe isebenzisa ikakhulu iindlela zokupholisa (ezinje ngendalo, ukuqhuba kunye nemitha).

Imodeli yebhodi yesekethe eyenziwe lula

Ngaphambi kokumodareyitha, hlalutya izixhobo eziphambili zokufudumeza kwibhodi yesekethe, ezinje ngeetyhubhu ze-MOS kunye neebhloko zesekethe ezihlanganisiweyo. Ezi zinto ziguqula uninzi lwamandla alahlekileyo kubushushu ngexesha lokusebenza. Ke ngoko, ezi zixhobo kufuneka ziqwalaselwe kwimodeli.

Ukongeza. Abagcini ngokuqhuba umbane kuphela, kodwa baqhuba nobushushu kuyilo. Ukuqhutywa kobushushu kunye nendawo yokuhambisa ubushushu zinkulu kakhulu. Ibhodi yesekethe yinxalenye ebalulekileyo yesekethe ye-elektroniki. Ubume bayo benziwe nge-epoxy resin substrate kunye nefoyile yobhedu egutyungelwe njengomqhubi. Ubukhulu be-epoxy resin substrate yi-4mm kwaye ubukhulu be-foil foil yi-0.1mm. Ubushushu be-conductivity yobhedu yi-400W / (m ℃), ngelixa i-epoxy resin iyi-0.276w / (m ℃) kuphela. Nangona ifoyile yobhedu eyongeziweyo icekeceke kwaye ilungile, inefuthe elomeleleyo lokukhokela kubushushu, ngenxa yoko ayinakungahoywa kwimodeli.