- 22

- Sep

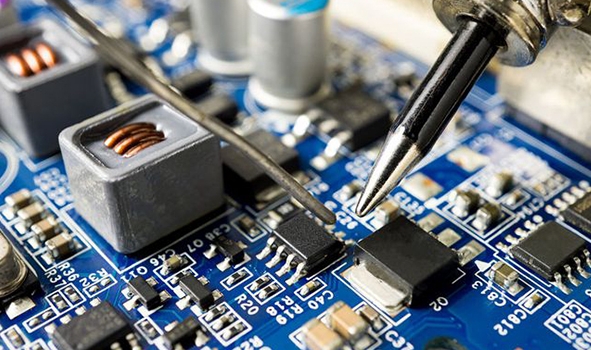

Ungakuthuthukisa kanjani ukuthembeka okushisayo kwe-PCB?

Ungakuthuthukisa kanjani ukuthembeka okushisayo kwe I-PCB?

Ngokuvamile, ukusatshalaliswa kwe-foil yethusi ku PCB kuyinkimbinkimbi kakhulu futhi kunzima ukumodela ngokunembile. Ngakho-ke, lapho ukumodela, kuyadingeka ukwenza lula ukwakheka kwentambo bese uzama ukwenza imodeli ye-ANSYS eduze nebhodi lesifunda langempela. Izinto ze-elekthronikhi ebhodini lesifunda nazo zingalingiswa ngokumodela okwenziwe lula, njengamashubhu we-MOS, amabhlogo wesifunda ahlanganisiwe, njll.

Ukuhlaziywa okushisayo kokucutshungulwa kwe-chip kungasiza abaklami ukuthi banqume ukusebenza kagesi kwezingxenye ku PCB wesifunda ibhodi nokuthi izingxenye noma ibhodi lesifunda lizoshisa ngenxa yokushisa okuphezulu. Ukuhlaziywa okulula okushisayo kubala kuphela izinga lokushisa elijwayelekile lebhodi lesifunda, futhi okuyinkimbinkimbi kudinga ukusungula imodeli edlulayo yemishini ye-elekthronikhi enamabhodi wesifunda amaningi. Ukunemba kokuhlaziywa okushisayo ekugcineni kuncike ekunembeni kokusetshenziswa kwamandla kwengxenye enikezwe ngabaqambi bebhodi lesifunda.

Kuzinhlelo eziningi, isisindo nosayizi womzimba kubaluleke kakhulu. Uma ukusetshenziswa kwamandla kwezakhi kuncane kakhulu, ukuphepha kokuklama kungahle kube phezulu kakhulu, ukuze idizayini yebhodi lesifunda yamukele inani lokusetshenziswa kwamandla okungahambisani nangempela noma okulondolozayo njengesisekelo sokuhlaziywa okushisayo. Ngokuphambene nalokho (futhi kubi kakhulu ngasikhathi sinye), ukwakheka kwezinto ezishisayo kuphansi kakhulu, okungukuthi, izinga lokushisa langempela lezinto liphakeme kunalokho okubikezelwe ngabahlaziyi. Izinkinga ezinjalo zivame ukuxazululwa ngokungeza amadivayisi wokuqothula ukushisa noma abalandeli ukupholisa ibhodi lesifunda. Lezi zesekeli zangaphandle zandisa izindleko futhi zandisa isikhathi sokukhiqiza. Ukungeza abalandeli ekwakhiweni nakho kuzoletha izinto ezingazinzile ekuthembekeni. Ngakho-ke, ibhodi lesifunda lisebenzisa izindlela ezisebenzayo zokupholisa (njenge-convection yemvelo, ukuqhutshwa kwemisebe kanye nemisebe).

Ukwenza imodeli kwebhodi lesifunda okwenziwe lula

Ngaphambi kokumodela, hlaziya amadivayisi amakhulu wokushisa ebhodini lesifunda, njengamashubhu we-MOS namabhulokhi wesifunda ahlanganisiwe. Lezi zingxenye ziguqula amandla amaningi alahlekile abe ukushisa ngesikhathi sokusebenza. Ngakho-ke, lawa madivayisi adinga ukucatshangelwa ekumodeleni.

Ngaphezu kwalokho, ucwecwe lwethusi oluhlanganiswe njengomqhubi ebhodini lesifunda substrate kufanele futhi lubhekwe. Abagcini nje ngokuqhuba ugesi, kepha futhi baqhuba nokushisa ekwakhiweni. Ukuhanjiswa kwawo okushisayo nendawo yokudlulisa ukushisa kukhulu ngokuqhathaniswa. Ibhodi lesifunda liyingxenye ebalulekile yesifunda se-elekthronikhi. Isakhiwo saso sakhiwe nge-epoxy resin substrate nocwecwe lwethusi oluhlanganiswe nomqhubi. Ubukhulu be-epoxy resin substrate bungu-4mm futhi ubukhulu bocingo lwethusi ngu-0.1mm. Ukuqhutshwa kokushisa kwethusi kungu-400W / (m ℃), kanti lokho kwe-epoxy resin kungu-0.276w / (m ℃) kuphela. Yize ucwecwe lwethusi olungeziwe luncane kakhulu futhi luhle, lunomphumela oqinile wokuqondisa ekushiseni, ngakho-ke alunakunakwa ekumodeleni.