- 18

- Sep

PCB (bọọdụ sekit e biri ebi) Okwu mmalite

E Bipụtara Circuie Board (PCB) is short for Printed circuit Board. Usually in insulation material, according to the predetermined design, made of printed circuit, printed components or a combination of both conductive graphics called printed circuit. The conductive graph of the electrical connection between components provided on the insulating substrate is called printed circuit. In this way, the printed circuit or printed line of the finished board is called printed circuit board, also known as printed board or printed circuit board.

PCB dị mkpa maka ihe fọrọ nke nta ka ọ bụrụ akụrụngwa elektrọnik niile anyị nwere ike ịhụ, site na elekere elektrọnik, ihe mgbako na kọmpụta nkịtị ruo na kọmpụta, akụrụngwa nkwukọrịta na sistemụ ngwa agha. Ọ bụrụhaala na enweghị akụrụngwa elektrọnik dị ka okirikiri agbakwunyere, a na -eji PCB maka njikọ eletrik dị n’etiti ha. Ọ na -enye nkwado n’ibu maka mgbakọ dị iche iche nke ngwa elektrọnik dị ka okirikiri agbakwunyere, na -achọpụta eriri na njikọ eletriki ma ọ bụ mkpuchi eletriki n’etiti ngwa elektrọn dị iche iche dị ka okirikiri agbakwunyere, ma na -enye njirimara eletriki achọrọ, dị ka njiri mara njiri mara, wdg. inye akpaka solder igbochi eserese; Nye mkpụrụedemede njirimara na eserese maka nrụnye akụrụngwa, nyocha na ndozi.

Kedu ka esi eme PCBS? Mgbe anyị mepere mpịakọta mkpịsị aka nke kọmpụta nwere ebumnuche, anyị nwere ike ịhụ ihe nkiri dị nro (ihe mkpuchi na-agbanwe agbanwe) nke ejiri eserese ọcha na-acha ọcha (mado ọlaọcha) na eserese eserese nwere ike. N’ihi usoro mbipụta ihuenyo zuru ụwa ọnụ iji nweta eserese a, yabụ anyị na -akpọ bọọdụ sekit a ebipụtara na -agbanwe osisi mpe mpe mpe akwa. Ọ dị iche na motherboards, kaadị eserese, kaadị netwọkụ, modem, kaadị ụda na bọọdụ sekit e biri ebi na ngwa ụlọ anyị na -ahụ na Computer City. A na-eji ihe eji eme ihe eji eme ihe (nke a na-ejikarị maka otu akụkụ) ma ọ bụ akwa akwa iko (nke a na-ejikarị maka ihu abụọ na ọtụtụ akwa), phenolic pre-impennated ma ọ bụ resin epoxy, otu ma ọ bụ n’akụkụ abụọ nke elu ahụ ejikọtara na ya. akwụkwọ ọla kọpa wee mezie ọgwụgwọ. Ụdị bọọdụ sekit a na -ekpuchi bọọdụ akwụkwọ ọla kọpa, anyị na -akpọ ya osisi siri ike. Mgbe ahụ anyị na -eme bọọdụ sekit ebi ebi, anyị na -akpọ ya kọọdụ sekit siri ike ebipụtara. A na-akpọ bọọdụ sekit ebipụta nwere eserese sekit ebipụta n’otu akụkụ, na bọọdụ sekit ebipụtara nwere eserese sekit ebipụtara n’akụkụ abụọ na-ejikọ ọnụ n’akụkụ abụọ site na ịmegharị oghere, anyị na-akpọ ya okpukpu abụọ. -nke. Ọ bụrụ na ị na-eji ihe mkpuchi okpukpu abụọ, ụzọ abụọ maka akwa elu ma ọ bụ mkpuchi abụọ, ihe mgbochi abụọ nke otu mpụta nke bọọdụ sekit ebipụtara, site na sistemụ idobe na ihe nrapado mkpuchi ọzọ na njikọ eserese eserese dị ka atụmatụ chọrọ nke sekit e biri ebi. bọọdụ na -aghọ bọọdụ sekit ebipụta anọ, isii, makwaara dị ka multilayer printed circuit board. Enwere ugbu a karịa ọkwa 100 nke bọọdụ sekit bara uru.

Usoro mmepụta nke PCB dị mgbagwoju anya, nke gụnyere usoro dị iche iche, site na nhazi igwe dị mfe ruo nhazi nhazi siri ike, gụnyere mmeghachi omume kemịkalụ nkịtị, fotochemistry, electrochemistry, thermochemistry na usoro ndị ọzọ, ihe enyemaka kọmputa (CAM) na ihe ọmụma ndị ọzọ. . Na usoro nsogbu mmepụta ihe, ọ ga -ezutekwa nsogbu ọhụrụ na nsogbu ụfọdụ n’ime achọpụtaghị ihe kpatara ya, n’ihi na usoro mmepụta ya bụ ụdị ahịrị na -aga n’ihu, njikọ ọ bụla na -ezighi ezi ga -akpata mmepụta n’ofe bọọdụ ma ọ bụ Nsonaazụ nke ọnụ ọgụgụ buru ibu, bọọdụ sekit ebipụtara ma ọ bụrụ na enweghị mpekere nrụgharị, ndị injinia nhazi nwere ike bụrụ nrụgide, ọtụtụ ndị injinia na -ahapụ ụlọ ọrụ ahụ rụọ ọrụ na ahịa na ọrụ nka maka akụrụngwa PCB ma ọ bụ ụlọ ọrụ ihe.

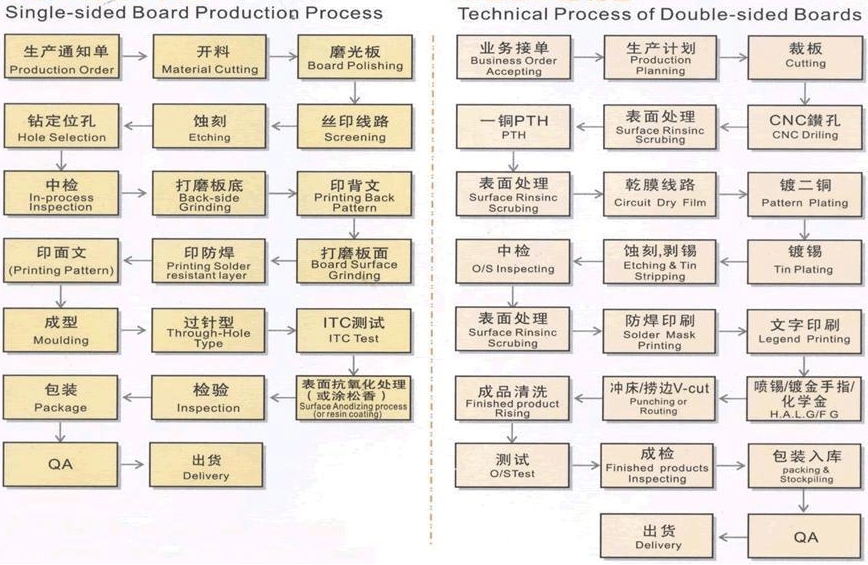

Iji ghọtakwuo PCB, ọ dị mkpa ịghọta usoro mmepụta nke na-abụkarị bọọdụ sekit nwere akụkụ nwere akụkụ abụọ na bọọdụ multilayer nkịtị, iji mee ka nghọta ya mikwuo emie.

Single-sided rigid printed board: – single copper clad – blanking to scrub, dry), drilling or punching – > screen printing lines etched pattern or using dry film resistance to curing check fix plate, copper etching and dry to resist printing material, to scrub, dry, screen printing resistance welding graphics (commonly used green oil), UV curing to character marking graphics screen printing, UV curing, preheating, punching, and the shape – electric open and short circuit test – scrubbing, drying → pre-coating welding anti-oxidant (dry) or tin-spraying hot air leveling → inspection packaging → finished products factory.

Ogwe e biri ebi siri ike nwere akụkụ abụọ:-mbadamba ihe mkpuchi ọla kọpa nwere akụkụ abụọ-oghere-laminated-nc drill guide hole-nnyocha, scrub deburring-plating chemical (metallization hole)-mkpa mkpuchi ọla kọpa (bọọdụ zuru oke)-nyocha nyocha-> ihuenyo na -ebipụta eserese sekit na -adịghị mma, ọgwụgwọ (ihe nkiri akọrọ/ihe nkiri mmiri, ikpughe na mmepe) – nyocha na ịrụzi efere – plating eserese na teepu electroplating (nkwụsị nzere nke nickel/ọla edo) -> ibipụta ihe (mkpuchi) – etching ọla kọpa. – (tin annealing) iji kpochapụ ihe dị ọcha, nke a na -ejikarị eme ihe nbipụta nbipụta na -eguzogide ịgbado ọkụ ọkụ na -agwọ mmanụ na -acha akwụkwọ ndụ (ihe nkiri akọrọ foto ma ọ bụ ihe nkiri mmiri, ikpughe, mmepe na ọgwụgwọ ọkụ, na -ekpochakarị mmanụ na -acha akwụkwọ ndụ akwụkwọ ndụ) na nhicha akọrọ, iji hụ nbipụta ihuenyo. eserese eserese, ịgwọ ọrịa, (tin ma ọ bụ ihe mkpuchi ihe mkpuchi ihe ọkụkụ) iji mepụta nhazi, nhicha, ihicha na nnwale eletriki, nkwakọ ngwaahịa na ngwaahịa emechara.

Site na usoro iji mezie usoro nke ọtụtụ ihe na-asọba n’ime akwa mkpuchi ọla kọpa nwere akụkụ nwere akụkụ abụọ, na-ehichapu oghere oghere, rapara na mkpuchi akọrọ ma ọ bụ mkpuchi iji guzogide ikpughe, mmepe na etching na ihe nkiri. -nlele n’ime-(mmepụta ahịrị dị n’èzí nke laminates ọla kọpa nwere otu akụkụ, B-mpempe akwụkwọ njikọta, nyocha mpempe akwụkwọ njikọta, oghere itinye oghere) iji laminate, ọtụtụ njikwa njikwa-> Oghere na nyocha tupu ọgwụgwọ na plating ọla kọpa-bọọdụ zuru oke na mkpuchi mkpuchi mkpuchi mkpuchi ọla kọpa – jidesie ike iguzogide plating ihe nkiri akọrọ ma ọ bụ mkpuchi na onye na -ahụ maka ihe mkpuchi iji kpughee ikpughere ala, mmepe na idozi efere – electroplating eserese eserese – ma ọ bụ nickel/plating gold na electroplating tin lead alloy na fim na etching – ịlele – ihuenyo mbipụta na -eguzogide ịgbado ọkụ eserese ma ọ bụ ọkụ butere nguzogide ịgbado ọkụ eserese – eserese e biri ebi – (ikuku ikuku na -ekpo ọkụ ma ọ bụ ihe ọkụkụihe nkiri ịgbado ọkụ) na njikwa ọnụọgụ ọdịdị nhicha, nhicha, ihicha dete nchọpụta njikọ eletriki, nyocha ngwaahịa emechara, ụlọ nrụpụta ihe.

Enwere ike ịhụ ya site na eserese usoro a na-emepụta usoro multilayer site na usoro ịmegharị ihu abụọ. Na mgbakwunye na usoro akụkụ abụọ, ọ nwere ọtụtụ ọdịnaya pụrụ iche: oghere dị n’ime nwere metallized, mkpọpu mmiri na mmetọ epoxy, sistemụ ọnọdụ, mkpuchi, na ihe pụrụ iche.

Our common computer board card is basically epoxy glass cloth double-sided printed circuit board, which has one side is inserted components and the other side is the component foot welding surface, can see that the solder joints are very regular, the component foot discrete welding surface of these solder joints we call it the pad. Why don’t the other copper wires have tin on them? Because in addition to the solder plate and other parts of the need for soldering, the rest of the surface has a layer of wave resistance welding film. Its surface solder film is mostly green, and a few use yellow, black, blue, etc., so the solder oil is often called green oil in THE PCB industry. Its function is to prevent wave welding bridge phenomenon, improve welding quality and save solder and so on. It is also a permanent protective layer of printed board, can play the role of moisture, corrosion, mildew and mechanical abrasion. From the outside, the surface is smooth and bright green blocking film, which is photosensitive to the film plate and heat curing green oil. Not only the appearance is better, it is important that the pad accuracy is high, so as to improve the reliability of the solder joint.

Dị ka anyị nwere ike ịhụ na bọọdụ kọmputa, a na -etinye ihe mejupụtara n’ụzọ atọ. Usoro nrụnye nkwụnye maka nnyefe nke etinyere ngwa eletrọniki n’ime oghere na bọọdụ sekit ebipụtara. Ọ dị mfe ịhụ na bọọdụ sekit nwere ihu abụọ nwere oghere site na oghere dị ka ndị a: otu bụ oghere ntinye ngwa ngwa; Nke abụọ bụ ntinye akụrụngwa yana njikọta akụkụ abụọ site na oghere; Atọ bụ oghere dị mfe nwere ihu abụọ; Anọ bụ nrụnye efere ala na oghere idobe ya. Ụzọ mgbakwasa abụọ ndị ọzọ bụ ịwụnye elu na ịwụnye mgbawa ozugbo. N’ezie, enwere ike ịtụle teknụzụ ịwụnye mgbawa dị ka ngalaba nke teknụzụ na -agbago elu, ọ bụ mgbawa na -arapara na bọọdụ e biri ebi, wee jikọta ya na bọọdụ ebipụtara site na usoro ịgbado ọkụ waya ma ọ bụ usoro itinye eriri, usoro tụgharịrị, ụzọ ntụhie. usoro na teknụzụ nkwakọ ngwaahịa ndị ọzọ. Ala ịgbado ọkụ dị n’elu akụrụngwa.

Teknụzụ ịwụnye elu nwere uru ndị a:

(1) N’ihi nnukwu site na oghere ma ọ bụ olulu oghere njikọ teknụzụ na-ewepụ nke ukwuu site na bọọdụ ebipụtara, a na-eme ka njupụta wiring dị na bọọdụ ebipụtara, mpaghara bọọdụ ebipụtara belatara (n’ozuzu otu ụzọ n’ụzọ atọ nke nkwụnye nkwụnye ), na ọnụ ọgụgụ nke nhazi imewe na ọnụ ahịa bọọdụ ebipụta nwekwara ike belata.

(2) Reduced weight, improved seismic performance, the use of colloidal solder and new welding technology, improve product quality and reliability.

(3) Due to the increase of wiring density and lead length, the parasitic capacitance and parasitic inductance are reduced, which is more conducive to improving the electrical parameters of the printed board.

(4) Ọ dị mfe ịghọta akpaaka karịa nrụnye nkwụnye, melite ọsọ nrụnye na arụpụta ọrụ, ma belata ọnụ ahịa ọgbakọ ya.

Dị ka enwere ike ịhụ site na teknụzụ nchekwa elu dị n’elu, mmelite nke teknụzụ bọọdụ sekit ka mma site na nkwalite teknụzụ mkpọchi mgbawa na teknụzụ na -arị elu. Mbadamba kọmpụta ahụ anyị na -ahụ ugbu a na -egosi na osisi elu ya na -akwalite ọnụego ịrị elu n’akwụsịghị akwụsị. N’ezie, ụdị bọọdụ sekit a na -ejigharị eserese eserese na -ebi akwụkwọ enweghị ike imezu ihe ndị achọrọ. Yabụ, bọọdụ sekit dị elu dị elu, eserese eserese ya na eserese ịgbado ọkụ bụ sekit nwere mmetụta dị nro na usoro imepụta mmanụ akwụkwọ ndụ akwụkwọ ndụ nwere mmetụta.

With the development trend of high density circuit board, the production requirements of circuit board are becoming higher and higher. More and more new technologies are applied to the production of circuit board, such as laser technology, photosensitive resin and so on. The above is just some superficial introduction of the surface, there are many things in the production of circuit board due to space constraints, such as blind hole, winding board, teflon board, photolithography and so on. If you want to study in depth, you need to work hard.