- 18

- Sep

I-PCB (ibhodi yesekethe eprintiweyo) Intshayelelo

Ishicilelwe Circuie Board (PCB) imfutshane kwiBhodi yesekethe eprintiweyo. Ngokwesiqhelo kwizinto zokwambathisa, ngokokuyilwa kwangaphambili, okwenziwe ngesekethe eprintiweyo, izinto eziprintiweyo okanye indibaniselwano yazo zombini iigrafiki ezibizwa ngokuba ziisekethe eziprintiweyo. Igrafu eqhubayo yoqhagamshelo lombane phakathi kwezinto ezinikezelweyo kwisiseko sokubambelela sibizwa ngokuba yisekethe eprintiweyo. Ngale ndlela, isekethe eprintiweyo okanye umgca oprintiweyo webhodi egqityiweyo ibizwa ngokuba yibhodi yesekethe eprintiweyo, ekwabizwa ngokuba yibhodi eprintiweyo okanye ibhodi yesekethe eprintiweyo.

I-PCB ibalulekile phantse kuzo zonke izixhobo ze-elektroniki esinokuzibona, ukusuka kwiiwotshi zombane, iikhalityhuleyitha kunye neekhompyuter ngokubanzi ukuya kwiikhompyuter, izixhobo zonxibelelwano zombane kunye neenkqubo zezixhobo zomkhosi. Logama nje kungekho zinto zombane ezinje ngeesekethe ezihlanganisiweyo, i-PCB isetyenziselwa unxibelelwano lombane phakathi kwazo. Inikezela ngenkxaso yoomatshini kwindibano esisigxina yezinto ezahlukeneyo ze-elektroniki ezinje ngeesekethe ezihlanganisiweyo, iyayiqonda intambo kunye nokudityaniswa kombane okanye ukufakwa kombane phakathi kwezinto ezahlukeneyo zombane ezinje ngeesekethe ezihlanganisiweyo, kwaye inikezela ngeempawu zombane ezifunekayo, ezinje nge-impedance yempawu, njl. ukubonelela nge-solder yokuthintela igrafu ngokuzenzekelayo; Nika abalinganiswa bokuchonga kunye nemizobo yofakelo lwecandelo, uhlolo kunye nolondolozo.

Zenziwa njani iiPCBS? Xa sivula i-thumb drive yekhompyuter ejolise ngokubanzi, sinokubona ifilimu ethambileyo (iguquguqukayo yokwambathisa i-substrate) eprintwe ngesilivere-emhlophe (uncamathisela isilivere) yemizobo eqhubayo kunye nemizobo enokubakho. Ngenxa yendlela yokushicilela kwesikrini kwindalo iphela yokufumana le grafu, ke siyibiza le bhodi yesekethe eprintiweyo ukuguquguquka kwesilivere kwibhodi yesekethe eprintiweyo. Ezahlukileyo kwiibhodi zee-mama, amakhadi emizobo, amakhadi enethiwekhi, iimodem, amakhadi esandi kunye neebhodi zesekethe eziprintiweyo kwizixhobo zasekhaya esizibonayo kwisiXeko seKhompyuter. Izinto ezisisiseko ezisetyenzisiweyo zenziwe ngesiseko sephepha (esihlala sisetyenziselwa icala elinye) okanye isiseko selaphu leglasi (esihlala sisetyenziselwa amacala aphindwe kabini kunye nolwahlu oluninzi), i-phenolic okanye i-epoxy resin yangaphambi kokumitha, elinye okanye omabini amacala omhlaba athe g incwadi yobhedu emva koko yanyangwa ngelaminethi. Olu hlobo lwebhodi yesekethe lugubungela ibhodi yencwadi yobhedu, siyibiza ngokuba yibhodi eqinileyo. Emva koko senza ibhodi yesekethe eprintiweyo, siyibiza ngokuba yibhodi yesekethe eshicilelweyo. Ibhodi yesekethe eprintiweyo enemizobo yesekethe eprintiweyo kwelinye icala ibizwa ngokuba yibhodi enye yesekethe eprintiweyo, kwaye ibhodi yesekethe eprintiweyo enemizobo yesekethe eprintiweyo kumacala omabini inxibelelene kumacala omabini ngokusebenzisa umngxunya wesinyithi, kwaye siyibiza kabini ipaneli. Ukuba usebenzisa i-lining ephindwe kabini, indlela enye yoluhlu lwangaphandle okanye i-lining ezimbini, iibhloko ezimbini zendlela enye yebhodi yesekethe eprintiweyo, ngenkqubo yokuma kunye nezinye izinto zokuncamathela Ibhodi iba zine, ibhodi yesekethe eprintiweyo yesine, ekwabizwa ngokuba yi ibhodi yesekethe eprintiweyo. Ngoku kukho ngaphezu kwe-100 leebhodi zeebhodi zesekethe eziprintiweyo.

Inkqubo yokuveliswa kwePCB inzima kakhulu, ebandakanya uluhlu olubanzi lweenkqubo, ukusuka ekusebenzeni ngokulula koomatshini ukuya kulwenziwo oluntsonkothileyo, kubandakanya ukusabela okuqhelekileyo kwemichiza, i-photochemistry, i-electrochemistry, i-thermochemistry kunye nezinye iinkqubo, uyilo oluncediswa yikhompyuter (i-CAM) kunye nolunye ulwazi . Kwaye kwinkqubo yeenkqubo zemveliso kwaye iya kuhlala ihlangabezana neengxaki ezintsha kwaye ezinye iingxaki azifumananga isizathu sokunyamalala, kuba inkqubo yayo yemveliso luhlobo lwendlela eqhubekayo, naluphi na unxibelelwano olungalunganga luya kubangela imveliso kuyo yonke ibhodi okanye iziphumo zenani elikhulu lezinto ezilahliweyo, ibhodi yesekethe eprintiweyo ukuba akukho zinto zirisayikilishayo zokuphinda zisetyenziswe, iinjineli zenkqubo zinokuba noxinzelelo, uninzi lweenjineli zilushiya ushishino ziye kusebenza kwintengiso kunye neenkonzo zobuchwephesha zezixhobo zePCB okanye iinkampani zezixhobo.

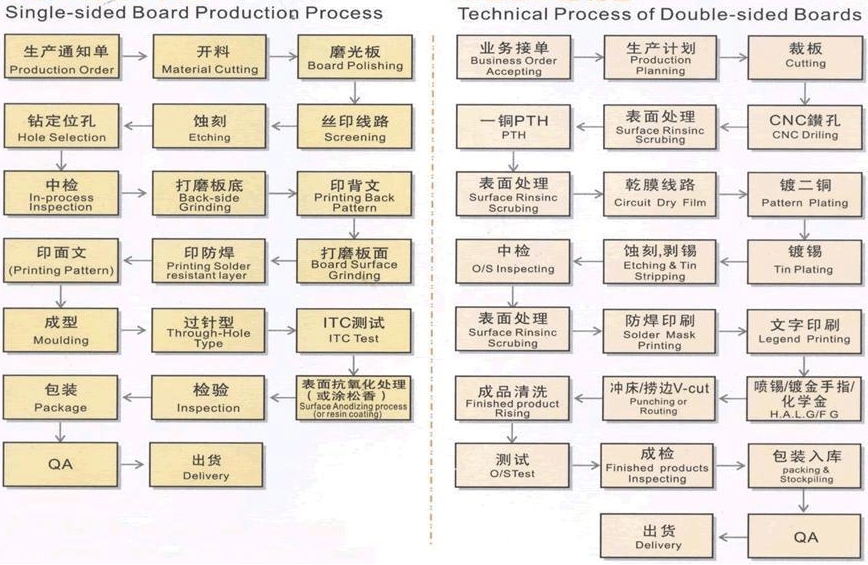

Ukuze uqhubeke uqonde i-PCB, kufuneka uqonde inkqubo yemveliso yecala elijikeleze icala elinye, ibhodi yesekethe eprintiweyo esecaleni kunye nebhodi yesiqhelo ye-multilayer, ukomeleza ukuqonda kwayo.

Iibhodi ezishicilelweyo ezingashicilelwanga zodwa: – ilokhwe enye yobhedu – ukungafihli into eyomileyo), ukubhola okanye ukubetha ngenqindi -> imigca yoshicilelo lwesikrini okanye ipatheni yokuthintela ifilimu eyomileyo ekunyangeni ipleyiti yokulungisa ukutshiza, ukoma, ukushicilela isikrini kwimizobo ye-welding (esetyenziswa ngokuxhaphakileyo ngeoyile eluhlaza), ukuphilisa i-UV kumatshini wokumakisha kwimizobo yokushicilela, ukuphilisa i-UV, ukutshisa, ukubetha, kunye nokubumba – uvavanyo lombane oluvulekileyo nolufutshane lwesekethe-ukhuhla, ukomisa → kwangaphambili i-welding anti-oxidant (eyomileyo) okanye i-tin-spraying hot air leveling → ukuhlolwa kokupakisha → iimveliso ezigqityiweyo.

Iibhodi ezishicilelweyo ezinamacala amabini: -ibhodi enekhedu enamacala amabini-engenanto- engenanto – elaminethiweyo – inc umngxunya wesikhombisi somngxunya – uhlolo, isikhuhli esirhabaxa – umchamo weekhemikhali Ukushicilelwa kwescreen kwimizobo yesekethe engalunganga, unyango (ifilimu eyomileyo / ifilimu emanzi, ukuvezwa kunye nophuhliso) -ukuhlolwa kunye nokulungiswa kweplati-umgca wemizobo kunye ne-electroplating tin (ukumelana nomhlwa we-nickel / igolide) -> ukuprinta izinto (ukutyabeka) -ubhedu – (i-annealing tin) yokuhlikihla okucocekileyo, okuqhelekileyo okusetyenziswa kwimizobo yokushicilela ukukhusela ukuhambisa ubushushu kunyanga ioyile eluhlaza (ifilimu eyomileyo yefilimu okanye ifilimu emanzi, ukubonakaliswa, ukukhula kunye nokuphilisa ubushushu, kuhlala kushushu ukuphilisa ioyile eluhlaza) kunye nokucoca okwomileyo Imizobo yomlinganiswa, ukuphilisa, (itin okanye ifilimu yokuwelda ekhuselweyo) ukwenza inkqubo, ukucoca, ukomisa kuvavanyo lokwenza umbane, ukupakisha kunye neemveliso ezigqityiweyo.

Ngokusebenzisa umngxunya wokunyibilikisa inkqubo yokuvelisa inkqubo ye-multilayer yokuhamba ukuya ngaphakathi kwimbasa yobhedu enxibe ukusika okunamacala amabini, ukukrola ukubola umngxunya wokubambelela, ukunamathela kwisambatho esomileyo okanye ukutyabeka ukumelana nokuvezwa, ukukhula kunye nokutsalwa kunye nefilimu -ukuqina kwangaphakathi kunye ne-oxidation -Ukutshekisha kwangaphakathi – (imveliso engaphandle yelayini enye enamacala alaminethiweyo, i-B – iphepha lokudibanisa, iphepha lokuhlola iphepha, umngxunya wokubekwa kwindawo yokubumba) ukwenza ulaminethi, ukubola kolawulo oluninzi-> Umngxunya kwaye ujonge ngaphambi konyango kunye nesingxobo sobhedu semichiza- ibhodi epheleleyo kunye nokuhlolwa kobhedu obuncinci bokuhlolwa kwetyhubhu-ukunamathela ekumeleni ifilimu okanye ukutyabeka kwiarhente yesingxobo ukunxiba ukuvezwa emazantsi, uphuhliso kunye nokulungisa i-plate-line graph electroplating-okanye i-nickel / igolide yokubeka kunye ne-electroplating tin lead alloy kwifilimu kunye nokutsalwa – itshekhi -Ukushicilelwa kwesikrini sokumelana nemizobo yewelding okanye ukukhanya kwimizobo yewelding yokukhanyaifilimu yewelding ekhuselweyo) kunye nolawulo lwamanani Ukuhlamba imilo → ukucoca, ukomisa → ukufumanisa uqhagamshelo lombane → ukuhlolwa kwemveliso okugqityiweyo → ukupakisha umzi mveliso.

Ingabonakala kwinkqubo yetshathi yokuhamba ukuba inkqubo ye-multilayer iphuhliswe kwinkqubo yentsimbi yobuso. Ukongeza kwinkqubo enamacala amabini, inemixholo eyahlukileyo eyahlukileyo: umngxunya wangaphakathi odityanisiweyo, ukubhola kunye nokususwa kwe-epoxy, inkqubo yokuma, ulweliso kunye nezinto ezizodwa.

Ikhadi lethu lebhodi yekhompyuter eliqhelekileyo ngokusisiseko liliglasi ye-epoxy yelayini enamacala amabini eprintiweyo ebhodi yesekethe, enecala elinye elifakelwe izinto kunye nelinye icala yindawo yokunyathela iinyawo, uyabona ukuba amalungu e-solder aqhelekile, icandelo le-welding discrete Umphezulu wala malungu e-solder siwabiza ngokuba yipad. Kutheni ezinye iingcingo zobhedu zingenazo iitoti kuzo? Ngenxa yokuba ukongeza kwiplate ye-solder kunye nezinye iinxalenye zesidingo se-soldering, indawo eseleyo inomgangatho wefilimu yokuchasana nokutshangatshangiswa. Umboniso wayo we-solder wefilimu ubukhulu becala uluhlaza, kwaye bambalwa basebenzisa utyheli, mnyama, luhlaza okwesibhakabhaka, njl.njl. Umsebenzi wayo kukuthintela into yokutsalwa kwebhulorho yamaza, ukuphucula umgangatho we-welding kunye nokugcina i-solder njalo njalo. Ikwangumaleko okhuselayo osisigxina webhodi eprintiweyo, inokudlala indima yokufuma, ukubola, ukungunda kunye nokuqaqanjelwa ngomatshini. Ukusuka ngaphandle, umphezulu ugudile kwaye uqaqambile oluhlaza uvimba ifilimu, ethi ifoto kwiflethi yefilimu kunye nobushushu obuphilisa ioyile eluhlaza. Ayisiyiyo kuphela imbonakalo ebhetele, kubalulekile ukuba ukuchaneka kwephedi kuphezulu, ukuze kuphuculwe ukuthembeka kwendibaniselwano.

Njengoko sinokubona kwibhodi yekhompyuter, izinto ezifakwe ngeendlela ezintathu. Inkqubo yofakelo lwe-plug-in lokuhambisa apho icandelo le-elektroniki lifakwa kumngxunya kwibhodi yesekethe eprintiweyo. Kulula ukubona ukuba ibhodi yesekethe eprintiweyo enamacala amabini enemingxunya imi ngolu hlobo lulandelayo: enye yinto elula yokufaka umngxuma; Okwesibini kukufakwa kwecandelo kunye nokunxibelelana kabini macala emngxunyeni; Isithathu lilula elinamacala amabini kumngxuma; Isine kukufakwa kwesiseko seplate kunye nomngxunya wokuma. Ezinye iindlela ezimbini zokunyusa ukunyusa umphezulu kunye nokufaka i-chip ngokuthe ngqo. Ngapha koko, itekhnoloji ethekisayo ethe ngqo ethembekileyo inokuqwalaselwa njengesebe lobuchwephesha bokunyusa umphezulu, yi-chip ethe nca ngqo kwibhodi eprintiweyo, emva koko idityaniswe kwibhodi eprintiweyo ngendlela yewelding okanye indlela yokulayisha ibhanti, indlela yeflip, umqadi okhokelayo indlela kunye nenye itekhnoloji yokupakisha. Umphezulu welding phezu kumphezulu wecandelo.

Itekhnoloji yokufaka umphezulu inezi zinto zilandelayo:

(1) Ngenxa enkulu ngokusebenzisa umngxuma okanye ukungcwatywa kwemingxunya yetekhnoloji yobuchwephesha ubukhulu becala isuswe yibhodi eprintiweyo, ukuxinana kweentambo kwibhodi eprintiweyo kuyaphuculwa, indawo yebhodi eprintiweyo iyancitshiswa (ngokubanzi isinye kwisithathu sokufakwa kweplagi ), kunye nenani loyilo loyilo kunye neendleko zebhodi eprintiweyo nayo inokuncitshiswa.

(2) Ukuncipha kobunzima, ukuphucula ukusebenza kwenyikima, ukusetyenziswa kwe-colloidal solder kunye netekhnoloji entsha ye-welding, ukuphucula umgangatho wemveliso kunye nokuthembeka.

(3) Ngenxa yokwanda koxinano lwe-wiring kunye nobude belothe, amandla e-parasitic kunye nokunyanzeliswa kwe-parasitic kuncitshisiwe, okulungele ukuphucula iiparameter zombane kwibhodi eprintiweyo.

(4) Kulula ukuqonda ukuzenzekelayo kunokufakelwa kwe-plug-in, ukuphucula isantya sokufaka kunye nemveliso yabasebenzi, kunye nokunciphisa iindleko zebandla ngokufanelekileyo.

Njengoko kunokubonwa kwitekhnoloji yokhuseleko yomphezulu womhlaba, ukuphuculwa kwetekhnoloji yebhodi yesekethe kuphuculwe ngokuphuculwa kwetekhnoloji yokupakisha ye-chip kunye netekhnoloji yokunyusa umphezulu. Ibhodi yekhompyuter esiyibonayo ngoku ikhadi layo elingaphezulu lifakela inqanaba lokunyuka ngokungapheliyo. Ngapha koko, olu hlobo lwebhodi yesekethe yokuphinda isebenzise ukuhanjiswa kwemizobo yokuhambisa kwimizobo ayikwazi ukuhlangabezana neemfuno zobugcisa. Ke ngoko, ibhodi yesekethe yokuchaneka okuqhelekileyo, imigca yayo yemigca kunye nemizobo ye-welding ziisekethe ezibuthathaka kunye nenkqubo yemveliso yeoyile eluhlaza.

Ngotyekelo lophuhliso lwebhodi yesekethe yokuxinana okuphezulu, iimfuno zemveliso yebhodi yesekethe ziya ziba phezulu nangaphezulu. Ngakumbi nangakumbi ubuchwepheshe obutsha zisetyenziswa kwimveliso ibhodi yesekethe, ezifana laser technology, nentlaka photosensitive njalo njalo. Oku kungasentla kukwaziswa nje komhlaba, kukho izinto ezininzi kwimveliso yebhodi yesekethe ngenxa yeengxaki zesithuba, ezinje ngemingxunya eyimfama, ibhodi ejijekayo, ibhodi ye-teflon, ifotolithography njalo njalo. Ukuba ufuna ukufunda nzulu, kuya kufuneka usebenze nzima.