- 04

- Oct

ʻO ka nīnau nīnau i ka ʻike maʻamau o ka papa kaapuni

Ke kaʻina hana hana Key o ka pae kiʻekiʻe PCB

1. Hoʻolauna i ka wehewehe inoa

Kaapuni paʻi – ma ka papa o kahi mea hoʻoheheʻe, hāʻawi i kahi ʻano conductive o nā pilina uila ma waena o nā mea, me nā mea pale.

Kaapuni paʻi – he kaapuni i hana ʻia i ke kaapuni paʻi, kahi ʻāpana i paʻi ʻia, a i ʻole ka hui ʻana o nā mea ʻelua, e like me ka hoʻolālā i hoʻonohonoho ʻia ma ka ʻili o nā mea hoʻoheheʻe.

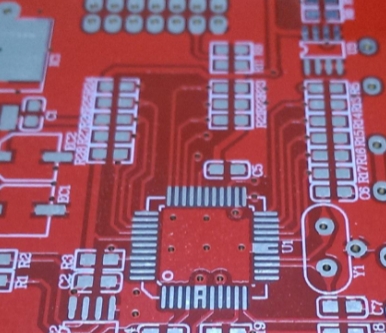

Kaapuni pai / kaapuni papa – ka manawa nui no nā papa kuʻi i hoʻopau ʻia me ke kaapuni paʻi a i ʻole ke kaapuni paʻi. Nā Mellors | | ai | | | Nā kaha kiʻi P CB, 1, 1, ai, 1 mahele 1 mākau i ka P | 1 CB pepa laʻana

ʻO ka PCB haʻahaʻa haʻahaʻa – Hana ʻia ka PCB me kahi uea i ʻoi aku ma mua o 0.3 mm (12 / 12mil) i ka laulā ma waena o ʻelua mau pā ma ke kuʻina o ka 2.54 mm maʻamau maʻamau.

ʻO ka PCB haʻahaʻa haʻahaʻa – Ua paʻi ʻia kahi papa i paʻi ʻia me nā kaula ʻelua ma kahi o 0.2 mm (8 / 8mil) i ka laulā ma waena o nā disks ʻelua ma ke kuʻina o ka 2.54 mm maʻamau maʻamau.

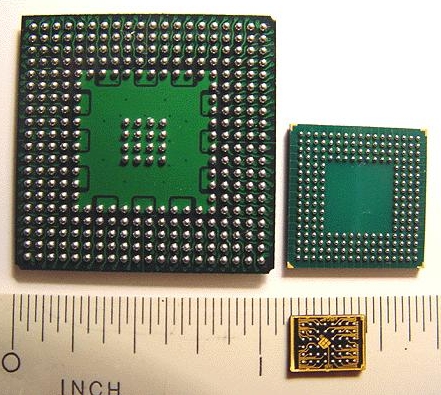

Papa paʻi kiʻekiʻe kiʻekiʻe – He papa pai i hana ʻia me ka nui me ʻekolu mau kaula ma waena o ʻelua mau pā ma ke kuʻina o ka 2.54 mm o ka laulā maʻamau o 0.1 a 0.15 mm (4-6 / 4-6mil).

2. He aha nā ʻano o nā kaapuni paʻi e like me ka substrate a me ka conductive kumu i hoʻohana ʻia? Nā Mellors | | ai | | | Nā kaha kiʻi PCB, 1, 1, ai, 1 mahele 1 mākau i ka P | 1 CB pepa laʻana

– Wahi a ka substrate i hoʻohana ʻia: ʻoʻoleʻa, maʻalahi, paʻa paʻa;

– Wahi a nā kiʻi conductive: hoʻokahi, pālua, multi-layer.

3. Wehewehe i ka hana o ke kaapuni paʻi a me nā ʻano o ka hana kaapuni paʻi.

– ʻO ka mea mua, hāʻawi ia i ke kākoʻo mechanical no ka papa kope PCB a me ka hoʻākoakoa o nā transistors, nā kaapuni hoʻohui, nā pale, nā capacitor, nā mea hoʻokomo a me nā mea ʻē aʻe.

ʻO ka lua, ʻike ia i ka pilina a me ka pilina uila ma waena o nā mea e like me transistors, nā huila i hoʻohui ʻia, nā resistors, nā capacitor a me nā inductors, a me nā mea uila e hālāwai me kona mau ʻano uila.

ʻO ka mea hope loa, hāʻawi ʻia nā hōʻailona a me nā kiʻi no ka nānā a me ka mālama ʻana i nā mea i ka kaʻina hui uila PCB, a hāʻawi ʻia nā kiʻi kuʻihakahaka no ka soldering nalu.

– Keʻenehana kiʻekiʻe, hoʻopukapuka kiʻekiʻe, kūlana kiʻekiʻe a me ka loaʻa kālā kiʻekiʻe. Nā Mellors | | ai | | | Nā kaha kiʻi P CB, 1, 1, ai, 1 mahele 1 mākau i ka P | 1 CB pepa laʻana

4. Hoʻohālikelike ʻia ka hoʻokaʻawale ʻana i ke kaʻina hana hana kaapuni i nā ʻano hana ʻelua? He aha nā mea maikaʻi o kēlā me kēia?

– Hoʻohui hana: pale i ka helu nui o ka hoʻopaʻa ʻana i ke keleawe, hoʻemi i ke kumukūʻai. ʻO ka hana ʻana o ka papa kope PCB maʻalahi, hoʻomaikaʻi i ka hoʻokō ʻana i ka hana. Hiki ke hoʻokō i nā kaula kaila a me nā ʻāpana flush. Hoʻonui ka hilinaʻi o ka lua metallized.

– Ka hana hōʻemi: ke ʻano oʻo, kūpaʻa a hilinaʻi hoʻi. Nā Mellors | | ai | | | Nā kaha kiʻi P CB, 1, 1, ai, 1 mahele 1 mākau i ka P | 1 CB pepa laʻana

5. He aha nā ʻano hana hoʻohui i hoʻohana ʻia i ka hana kaapuni paʻi? Kākau i ke kaʻina kaʻawale?

– Ka nui o nā hana hoʻohui: ʻeli, kiʻi, viscosifying lapaʻau (wā maikaʻi ʻole), plating keleawe electroless, hemo ʻana o resist.

– Ka hana hapa hapalua: ka ʻeli ʻana, ka lāʻau catalytic a me ka hoʻopili ʻana, plating keleawe electroless, kiʻi (electroplating resist), keleawe electroplating kiʻi (ʻaoʻao maikaʻi ʻole), ka pale kūʻē, ka ʻae ʻana i ka ʻokoʻa.

– Ke kaʻina hoʻohui hoʻohui: kiʻi (anti-etching), keleawe keleawe (pae maʻamau), hemo i ka pale pale, pale pale electroplating āpau, ʻeli, pale keleawe electroless i ka lua, e hoʻoneʻe i nā pale uila.

6. He aha nā ʻano o ke kaapuni paʻi i ka hana unuhi? Kākau i ke kahe o ke kaʻina o ka plating pā holoʻokoʻa a me ka plating kiʻi. Nā Mellors | | ai | | | Nā kaha kiʻi P CB, 1, 1, ai, 1 mahele 1 mākau i ka P | 1 CB pepa laʻana

– PCB plated non-perforated, PCB plated perforated, PCB plated perforated a me PCB i kau ʻia i luna.

– Pau electroplating pā (hana masking): blanking, ʻeli, metallization o nā lua, ka mānoanoa o ka electroplating pā holoʻokoʻa, ka mālama ʻana i luna, ka paʻi ʻana o ke ʻano masking ʻano kiʻiʻoniʻoni, hana ʻana i nā kiʻi uea maʻamau, ka hoʻopaʻa ʻana, ka wehe kiʻi ʻana, hoʻopili electroplating, hana ʻana i nā ʻano, ka nānā ʻana, ka paʻi ʻana o ka pale pale kuʻihao, ka papa ea wela, ka paʻi pūnaewele ʻana o nā hōʻailona hōʻailona, nā huahana i pau. Nā Mellors | | ai | | | Nā kaha kiʻi P CB, 1, 1, ai, 1 mahele 1 mākau i ka P | 1 CB pepa laʻana

–PCB kiʻi electroplating (ʻaʻohe pale keleawe pale pale pale): Pālua-ʻaoʻao papa keleawe-uhi kapa blanking, punching hoʻonoho puka, CNC ʻeli, nānā, deburring, lahilahi lahilahi electroless keleawe, electroplating keleawe, nana, palaki pā, pepili (a i ka paʻi paʻi ), hōʻike kiʻi (a hoʻōla paha), nānā hou ʻana, electroplating keleawe, kiʻi e electroplating piʻina kēpau oka a, hele i ke kiʻi ʻoniʻoni (a hemo paha) i paʻi ʻia, nānā hou ʻana, hoʻopaʻa ʻia ʻana, hoʻi hou i hope, hōʻike kaapuni ākea, maʻemaʻe, nā kiʻi kuʻihā kūʻē. , kuʻi nickel plating / gula, plug adhesive tape, wela ea hoʻohaʻahaʻa, hoʻomaʻemaʻe, pūnaewele paʻi hōʻailona, ʻano hana, hoʻomaʻemaʻe a hoʻomaloʻo, nānā, ʻōpala, nā huahana i pau.

7. Hiki ke hoʻokaʻawale ʻia ka ʻenehana uila i nā ʻano ʻenehana?

– ʻEnehana plating porous plating, ʻenehana plating pololei, ʻenehana adhesive conductive. Nā Mellors | | ai | | | Nā kaha kiʻi P CB, 1, 1, ai, 1 mahele 1 mākau i ka P | 1 CB pepa laʻana

8. He aha nā hiʻohiʻona nui o nā papa paʻi maʻalahi? He aha nā mea i hoʻokumu ʻia?

– Hiki a maʻalahi hoʻi e hoʻoliʻiliʻi i ka leo; Ka māmā māmā, kaulike kaulike maikaʻi, hilinaʻi kiʻekiʻe.

9. E wehewehe i nā hiʻohiʻona nui a me nā hoʻohana o rigid – PCB maʻalahi.

– Hoʻohui ʻia nā ʻāpana paʻa a maʻalahi hoʻi, hoʻopau i ka pono o nā mea hoʻopili, pili pono, hoʻoliʻiliʻi kaumaha, hoʻoliʻiliʻi miniaturization. Hoʻohana nui ʻia ka papa kope PCB i nā mea uila uila, nā kamepiula a me nā peripherals, nā pono hana kamaʻilio, nā pono aerospace a me nā pale kūloko a me nā pono koa. Nā Mellors | | ai | | | Nā kaha kiʻi P CB, 1, 1, ai, 1 mahele 1 mākau i ka P | 1 CB pepa laʻana

10. E wehewehe i nā ʻano o ka papa lina hoʻoheheʻe conductive.

– ʻenehana hana maʻalahi, hana pono kiʻekiʻe, haʻahaʻa kumu kūʻai, hoʻemi wai liʻiliʻi.

11. He aha ka nui PCB pilina?

– Papa pai ʻia i hana ʻia e nā lay a me nā kaula hao ma luna o kahi mea hoʻoheheʻe.

12. He aha ka papa hao i hoʻokumu ʻia i ka hao? He aha nā hiʻohiʻona nui?

– Ka huaʻōlelo nui no ka papa metala i pai ʻia i ka papa a me ka papa kila i paʻi ʻia. Nā Mellors | | ai | | | Nā kaha kiʻi P CB, 1, 1, ai, 1 mahele 1 mākau i ka P | 1 CB pepa laʻana

13. He aha ka PCB multilayer ʻaoʻao hoʻokahi? He aha nā hiʻohiʻona nui?

Hana i nā papa kaapuni multilayer ma ka PCB hoʻokahi. ʻO nā ʻano o ka papa PCB: ʻaʻole hiki ke kaohi wale i ka nalu electromagnetic kūloko i ka radiation o waho, akā hiki nō hoʻi ke pale i ke ākea o ka nalu electromagnetic kūwaho iā ia, ʻaʻole pono i ka metallization hole, ke kumu kūʻai haʻahaʻa, ke kaupaona māmā, hiki ke lahilahi.

14. Hoʻomaka pōkole i ka wehewehe a me ka hana ʻana i ka puni kaapuni multilayer?

– Hana ʻia kahi papa multi-layer pilina kiʻekiʻe i paʻi ʻia e ka alternating insulate layer a me ka conductive layer i ke ala o ka stacking layer ma ka papa o loko o ka papa multi-layer i hoʻopau ʻia, a hoʻohana manuahi ʻia nā puka makapō e alakaʻi ai ma waena o nā papa.