- 04

- Oct

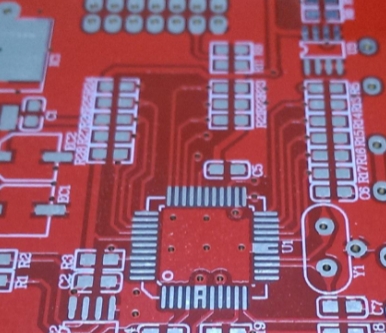

Question solving of basic knowledge of circuit board

Key production process control of high level PCB

1. Selelekela sa tlhaloso ea lebitso

Potoloho e hatisitsoeng – ka holim’a sesebelisoa se sirelletsang, e fana ka sebopeho sa khokahano ea motlakase lipakeng tsa likarolo, ho kenyeletsoa le likarolo tse sirelletsang.

Potoloho e hatisitsoeng – potoloho e entsoeng ka potoloho e hatisitsoeng, karolo e hatisitsoeng, kapa motswako oa tsena tse peli, ho latela moralo o reriloeng esale pele holim’a thepa e sirelletsang.

Printed circuit/circuit board — general term for insulating boards that have been finished with printed circuit or printed circuit. Mellors | | ai | | | P CB sample strips, 1, 1, ai, 1 division 1 skill the first P | 1 CB sample sheet

Low density density PCB – Mass e hlahisitse PCB e nang le terata e kholo ho feta 0.3 mm (12 / 12mil) ka bophara lipakeng tsa li-disk tse peli mateanong a tsela ea gridi e tloaelehileng ea 2.54 mm.

Medium density PCB – Boto e hatisitsoeng e entsoeng ka bongata e nang le lithapo tse peli tse ka bang 0.2 mm (8 / 8mil) ka bophara lipakeng tsa li-disk tse peli mateanong a tsela ea standard gridi ea 2.54 mm.

Boto e hatisitsoeng e phahameng haholo – Boto e hatisitsoeng e hlahisitsoeng ka bongata e nang le mehala e meraro lipakeng tsa li-disk tse peli mateanong a bophara ba gridi e tloaelehileng ea 2.54 mm ea 0.1 ho isa ho 0.15 mm (4-6 / 4-6mil).

2. What are the types of printed circuits according to the substrate and conductive pattern used? Mellors | | ai | | | PCB sample strips, 1, 1, ai, 1 division 1 skill the first P | 1 CB sample sheet

– Ho latela substrate e sebelisitsoeng: ho tenyetseha, ho tenyetseha, ho tenyetseha;

– Ho ea ka lits’oants’o tse tsamaisang: masoha, habeli, mekato e mengata.

3. Hlalosa tšebetso ea potoloho e hatisitsoeng le litšobotsi tsa indasteri ea potoloho e hatisitsoeng.

Pele ho tsohle, e fana ka ts’ehetso ea mochini bakeng sa tokiso ea board ea PCB le kopano ea li-transistor, li-circuits tse kopaneng, li-resistor, li-capacitor, inductors le likarolo tse ling.

Taba ea bobeli, e hlokomela khokahano ea wiring le motlakase lipakeng tsa likarolo tse kang li-transistor, lisekete tse kopaneng, li-resistor, li-capacitor le li-inductors, le motlakase oa motlakase ho fihlela litšobotsi tsa ona tsa motlakase.

Qetellong, litlhaku tse khethollang le lits’oants’o li fanoe bakeng sa tlhahlobo le tlhokomelo ea likarolo tsa ts’ebetso ea kopano ea elektroniki ea PCB, ‘me lits’oants’o tse thibelang tsa welding li fanoa bakeng sa ho kopanyelletsa leqhubu.

– Theknoloji e phahameng, matsete a phahameng, kotsi e kholo le phaello e phahameng. Babusi | | ai | | | P CB sampole hlobolisa, 1, 1, ai, 1 division 1 tsebo ea pele P | Leqephe la sampole la 1 la CB

4. Khatiso e hlophisitsoeng ea ts’ebetso ea potoloho e arotsoe haholo ka mekhoa efe e ‘meli? Melemo ea eng ka ‘ngoe ke efe?

– Mokhoa oa tlatsetso: qoba palo e kholo ea manonyeletso a koporo, fokotsa litšenyehelo. Ts’ebetso e bonolo ea tlhahiso ea board ea PCB, ntlafatsa ntlafatso ea tlhahiso. Mehala e nang le metsi le libaka tse phallang li ka fihlelleha. Ho tšepahala ha lesoba le nang le tšepe e ntlafalitsoe.

– Mokhoa oa ho fokotsa: ts’ebetso e holileng, e tsitsitseng le e tšepahalang. Babusi | | ai | | | P CB sampole hlobolisa, 1, 1, ai, 1 division 1 tsebo ea pele P | Leqephe la sampole la 1 la CB

5. Mefuta ea lits’ebetso tsa tlatsetso e sebelisoa ho etsa thepa e hatisitsoeng ea potoloho ke efe? Ngola ts’ebetso ka thoko?

– Mokhoa o akaretsang oa tlatsetso: ho cheka, ho nka litšoantšo, kalafo ea viscosifying (mohato o fosahetseng)

– Mokhoa o mong oa halofo ea ho eketsa: ho cheka, ho phekola ka mokhoa oa ho thusa le ho koala, ho roala koporo e se nang motlakase, ho nka litšoantšo (electroplating resist), koporo e hlakileng ea motlakase (karolo e mpe), khanyetso ea ho tlosa, phapang ea phapang.

– Mokhoa o mong oa tlatsetso: ho nka litšoantšo (anti-mananose), koporo ea manonyeletso (mohato o tloaelehileng), ho tlosa lera le hanelehang, seaparo se felletseng sa electroplating, ho cheka, ho roala koporo ka har’a mokoti, ho tlosa li-electroplating resist.

6. Mefuta ea potoloho e hatisitsoeng nakong ea ho tlosa ke efe? Ngola tšebetso ea phallo ea lipoleiti tse felletseng le lipalo tse hlakileng. Babusi | | ai | | | P CB sampole hlobolisa, 1, 1, ai, 1 division 1 tsebo ea pele P | Leqephe la sampole la 1 la CB

– E sa koahetsoeng ka PCB e entsoeng ka pente, e pentiloeng ka PCB e pentiloeng, e entsoe ka pente e pentiloeng le PCB e holim’a metsi.

– Whole poleiti electroplating (masking mokhoa): blanking, cheka, metallization ea masoba, thickening tsa poleiti electroplating kaofela, kalafo holim, pasting ea khanya masking mofuta omileng filimi, ho etsa tloaelehileng terata Grafiken, mananose, filimi tlosa, polaka electroplating, sebopeho sebetsa, tlhahlobo, khatiso ea seaparo sa tšepe se chesang, moea o chesang, khatiso ea marang-rang ea matšoao a tšoaeang, lihlahisoa tse felileng. Babusi | | ai | | | P CB sampole hlobolisa, 1, 1, ai, 1 division 1 tsebo ea pele P | Leqephe la sampole la 1 la CB

–PCB graphic electroplating (e se nang letho ea koporo ea ho roala filimi): Liboto tse koahetsoeng ka koporo tse koahelang mabokose, ho phunya sekoti, ho cheka CNC, ho hlahloba, ho senya, koporo e tšesaane e se nang motlakase, koporo ea electroplating, tlhahlobo, poleiti ea borashe, setikara (kapa khatiso ea skrine ), litšoantšo tse pepesang (kapa ho folisa), ho hlahloba li-retouching, koporo e khethang motlakase, lits’oants’o ke li-electroplating tin lead alloy. , polasetiki ea nickel / khauta ea polaka, theipi e khomarelang polaka, moea o chesang o batang, ho hloekisa, matšoao a khatiso ea marang-rang, ho sebetsana le sebopeho, ho hloekisa le ho omisa, tlhahlobo, ho paka, lihlahisoa tse felileng.

7. Theknoloji ea motlakase e ka aroloa ka mefuta ea mahlale afe?

– Tloaelehileng porous plating theknoloji, ka ho toba plating thekenoloji, conductive thekenoloji sekgomaretsi. Babusi | | ai | | | P CB sampole hlobolisa, 1, 1, ai, 1 division 1 tsebo ea pele P | Leqephe la sampole la 1 la CB

8. Litšobotsi tsa mantlha tsa liboto tse hatisitsoeng tse tenyetsehang ke life? Lisebelisoa tsa eona tsa motheo li na le eng?

– Flexible le foldable ho fokotsa molumo; Boima bo bobebe, ts’ebetso e ntle ea wiring, ts’epahalo e phahameng.

9. Hlalosa likarolo tsa mantlha le ts’ebeliso ea PCB e thata – e tenyetsehang.

– Likarolo tse thata le tse tenyetsehang li kopantsoe, ho felisa tlhoko ea likhokelo, khokahano e tšepahalang, phokotso ea boima, kopano ea miniaturization. Boto ea ho kopitsa ea PCB e sebelisoa haholo lisebelong tsa elektroniki tsa bongaka, likhomphutha le lisebelisoa, lisebelisoa tsa puisano, lisebelisoa tsa Aerospace le ts’ireletso ea naha le lisebelisoa tsa sesole. Babusi | | ai | | | P CB sampole hlobolisa, 1, 1, ai, 1 division 1 tsebo ea pele P | Leqephe la sampole la 1 la CB

10. Hlalosa litšobotsi tsa conductive sekgomaretsi hatisitsoeng boto.

– Theknoloji e bonolo ea ts’ebetso, ts’ebetso e phahameng ea tlhahiso, theko e tlase, metsi a litšila a fokolang.

11. What is multiple wiring PCB?

– Boto e hatisitsoeng e entsoeng ka ho beha mehala ea tšepe ka kotloloho ho substrate e sirelletsang.

12. Boto e hatisitsoeng ka tšepe ke eng? Lintlha tsa eona tsa mantlha ke li fe?

– Kakaretso ea poleloana e reng boto e hatisitsoeng ea tšepe le tšepe e hatisitsoeng ea tšepe. Babusi | | ai | | | P CB sampole hlobolisa, 1, 1, ai, 1 division 1 tsebo ea pele P | Leqephe la sampole la 1 la CB

13. PCB e nang le lehlakore le le leng ke eng? Lintlha tsa eona tsa mantlha ke li fe?

Tlhahiso ea liboto tse ngata tsa potoloho ka PCB e le ‘ngoe. Litšobotsi tsa boto ea PCB: ha e khone feela ho thibela leqhubu le ka hare la motlakase ho mahlaseli a kantle, empa hape e ka thibela tšitiso ea leqhubu la motlakase oa kantle ho lona, ha e hloke metallization ea lesoba, theko e tlase, boima bo bobebe, e ka ba tšesaane.

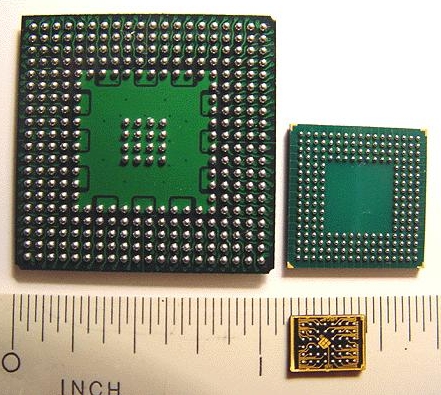

14. Kenyelletso e khuts’oane ea tlhaloso le tlhahiso ea methati e mengata e hatisitsoeng?

– Boto e hatisitsoeng ea wiring e nang le mekato e mengata e entsoe ka ho chenchana lera le tsela e tsamaisang tsela ea ho bokella lera le kahare la boto e phethiloeng ea mekato e mengata, ‘me masoba a foufetseng a sebelisoa ka bolokolohi ho tsamaisa lipakeng tsa likarolo.