- 05

- Oct

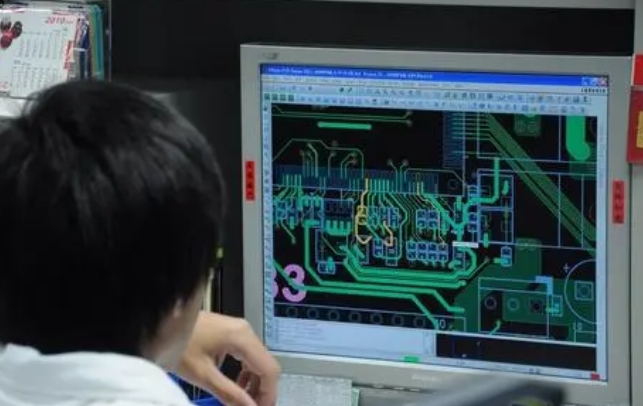

Zidule zisanu ndi chimodzi za kapangidwe ka PCB

Zidule zisanu ndi chimodzi za PCB kapangidwe kake

1. Kamangidwe

Choyamba, ganizirani kukula kwa PCB. Pamene kukula kwa PCB dera bolodi ndi waukulu kwambiri, mzere kusindikizidwa ndi wautali, impedance ukuwonjezeka, odana mphamvu phokoso amachepetsa ndi mtengo ukuwonjezeka; Ngati ndi yaying’ono kwambiri, kutaya kwanyengo kumakhala kovuta, ndipo mizere yoyandikira ndiyosavuta kusokonezedwa. Pambuyo kudziwa kukula kwa PCB, kudziwa malo a zigawo zikuluzikulu zapadera. Pomaliza, zigawo zonse za dera zimakonzedwa molingana ndi magwiridwe antchito a dera.

Mfundo izi zikuyenera kuwonedwa pozindikira malo azinthu zapadera:

(1) Fupikitsani zingwe pakati pazigawo zamafupipafupi momwe zingathere, ndipo yesetsani kuchepetsa magawo omwe amagawika komanso kusokonezedwa kwamagetsi. Zigawo zomwe zingasokonezeke sizikhala pafupi kwambiri, ndipo zopangira ndi zotulutsa zidzakhala kutali momwe zingathere.

(2) Pakhoza kukhala kusiyana kwakukulu pakati pazipangizo zina kapena mawaya, chifukwa chake mtunda pakati pawo uyenera kukulitsidwa kuti tipewe kufupika kwakanthawi mwangozi komwe kumachitika chifukwa chakutuluka. Zigawo zamagetsi zamagetsi zimakonzedwa m’malo osavuta kukhudza nthawi yomwe mukutumiza.

(3) Udindo wokhala ndi dzenje loyikapo mbale yomwe idasindikizidwa ndi chithandizocho chizisungidwa.

Malinga ndi magwiridwe antchito a dera, masanjidwe azigawo zonse za dera amayenera kutsatira mfundo izi:

(1) Konzani malo oyendetsa dera lililonse mogwirizana ndi momwe dera likuyendera, pangani mawonekedwe oyenera kuti mayendedwe azizungulira, ndikusunga chizindikirocho mozungulira momwe zingathere.

(2) Tengani zigawo zikuluzikulu za dera lililonse logwirira ntchito ngati likulu ndi mawonekedwe mozungulira. The zigawo zikuluzikulu adzakhala wogawana, mwaukhondo ndi yaying’ono anakonza pa PCB lapansi. Zotsogolera ndi kulumikizana pakati pazigawo zizichepetsedwa ndikufupikitsidwa momwe zingathere.

(3) Pazigawo zomwe zimagwira ntchito pafupipafupi, magawo ogawa pakati pazinthu ayenera kulingaliridwa. Ma circuits ambiri, zigawo zikuluzikulu zizikonzedwa mofananira momwe zingathere. Mwanjira imeneyi, si zokongola zokha, komanso zosavuta kusonkhanitsa ndi kuwotcherera, komanso zosavuta kupanga.

(4) Zigawo zomwe zili m’mphepete mwa bolodi la dera nthawi zambiri zimakhala zosakwana 2mm kutali ndi m’mphepete mwa bolodi. Mawonekedwe abwino kwambiri a bolodi lazoyenda ndi mapangidwe. Kukula kwake ndi 3: 2 mpaka 4: 3. Kukula kwapamwamba kwa bolodi loyenda ndikoposa 200x150mm, mphamvu yamakina oyang’anira dera izilingaliridwa.

2. Kulumikizana

Mfundo za zingwe ndi izi:

(1) Makondakitala omwe amagwiritsidwa ntchito m’malo olowetsera ndi kutulutsa zinthu azipewa kuyandikira pafupi momwe angathere. Ndi bwino kuwonjezera waya pakati pa mizere kuti mupewe kulumikizana ndi mayankho.

(2) Kutalika kocheperako kwa wochititsa kusindikizidwa kumatsimikiziridwa makamaka ndi mphamvu yolumikizira pakati pa wochititsa ndi mbale yolumikizira komanso momwe ikuyendera pakadali pano.

(3) Kupindika kwa waya wosindikizidwa nthawi zambiri kumakhala kozungulira kozungulira, ndipo ngodya yolondola kapena ngodya yomwe ikuphatikizidwa imakhudza magwiridwe antchito amagetsi pafupipafupi. Kuphatikiza apo, yesetsani kupewa kugwiritsa ntchito zojambulazo zamkuwa zazikuluzikulu, apo ayi, kukulitsa kwa zojambulazo zamkuwa ndikugwa ndizosavuta kuchitika mukatenthedwa kwanthawi yayitali. Pakafunika kugwiritsira ntchito zojambulazo zamkuwa, ndibwino kugwiritsa ntchito gridi, yomwe ingathandize kuthetsa gasi wosakhazikika womwe umapangidwa ndi kutentha kwa zomatira pakati pa zojambulazo zamkuwa ndi gawo lapansi.

3. Pad

Phando la pad pad (mu-mzere chipangizo) ndilokulirapo pang’ono kuposa kutsogolera kwa chipangizocho. Ngati pad ndi yayikulu kwambiri, ndikosavuta kupanga soldering yabodza. Dera lakunja D la pedi nthawi zambiri silikhala lochepera (D + 1.2) mm, pomwe D ndiye gawo loyambira. Kwa ma circuits apamwamba kwambiri a digito, the pad osachepera awiri amatha kukhala (D + 1.0) mm.

Njira zosokoneza za PCB ndi dera:

Mapangidwe odana ndi zosokoneza a board board osindikizidwa amagwirizana kwambiri ndi dera lawolo. Apa, ndi njira zochepa zokha za PCB zotsutsana ndi zosokoneza zomwe zafotokozedwa.

1. Kapangidwe kazingwe zamagetsi

Malinga ndi zomwe gulu lazosindikiza lidakalipo, yesetsani kukulitsa m’lifupi mwa mzere wamagetsi ndikuchepetsa kutsutsana. Nthawi yomweyo, pangani kuwongolera kwa chingwe champhamvu ndi waya wapansi mogwirizana ndi kuwongolera kwa kufalitsa deta, komwe kumathandizira kukweza phokoso lotsutsana ndi phokoso.

2. Loti kapangidwe

Zomwe kapangidwe ka waya wapansi ndi:

(1) Digital ndi analog zimagawanika. Ngati pali ma circuits olondola komanso ma circuits olinganizidwa pa board board, adzalekanitsidwa momwe angathere. Mfundo imodzi yofananira ndi nthaka idzakhazikitsidwa kuti iziyenda mozungulira pafupipafupi momwe zingathere. Ngati kuli kovuta kulumikiza zingwe zenizeni, zimatha kulumikizidwa pang’ono pang’ono kenako nkugwirizana chimodzimodzi. Mipikisano mfundo grounding adzakhala anatengera dera mkulu-pafupipafupi, waya nthaka adzakhala waufupi ndi lendi, ndipo gululi ngati lalikulu-dera zojambulazo nthaka adzagwiritsidwa ntchito mozungulira zigawo mkulu-pafupipafupi ngati kuli kotheka.

(2) Chingwe cholowera pansi chidzakhala chokulirapo momwe zingathere. Ngati waya wokhazikitsidwa wapangidwa ndi waya wosokedwa, maziko omwe angasinthe amasintha pakadali pano, kuti magwiridwe antchito amawu achepe. Chifukwa chake, waya wokhazika uyenera kukulitsidwa kuti udutse katatu katatu kololeka papulatifomu. Ngati ndi kotheka, waya wokhazikika udzakhala wopitilira 2 ~ 3mm.

(3) Chingwe cholowera pansi chimakhala chotseka. Kwa matabwa osindikizidwa omwe amangokhala ndi ma digito a digito, dera lokhazikika limakonzedwa mgulu limodzi, lomwe lingathandize kuti phokoso lisamveke bwino.

4. Decoupling capacitor kasinthidwe

Imodzi mwanjira zodziwika bwino za kapangidwe ka PCB ndikukhazikitsa ma decap capacitors oyenera mbali iliyonse yayikulu ya PCB. Mfundo yayikulu yosinthira decoupling capacitor ndi:

(1) Mphamvu yamagetsi yolumikizira imagwirizana ndi 10 ~ 100uF electrolytic capacitor. Ngati ndi kotheka, ndibwino kulumikizana kuposa 100uF.

(2) Momwemo, chipangizo chilichonse chophatikizika chimakhala ndi 0.01uF ~ 0.1uF ceramic chip capacitor. Pakakhala kusiyana kokwanira mu bolodi losindikizidwa, 1 ~ 10PF capacitor itha kukonzedwa tchipisi 4 ~ 8.

(3) Zipangizo zomwe zimakhala ndi phokoso lofooka komanso kusintha kwamphamvu pakutseka, monga RAM ndi zida zosungira za ROM, ma decoupling capacitors azilumikizidwa mwachindunji pakati pa chingwe chamagetsi ndi waya wapansi wa chip.

5. Kudzera kamangidwe kabowo

Mumapangidwe a PCB othamanga kwambiri, ma vias omwe amawoneka ngati osavuta nthawi zambiri amabweretsa zoyipa zazikulu pakupanga dera. Pofuna kuchepetsa mavuto obwera chifukwa cha vias, tikhoza kuyesetsa momwe tingapangire

Poganizira mtengo wake ndi mtundu wa ma siginolo, kusankha koyenera kudzera pa kukula kumasankhidwa. Mwachitsanzo, kwa 1-6 wosanjikiza kukumbukira gawo la PCB, ndi bwino kusankha 10 / 10MIL (kuboola / pad) vias. Kwa matabwa ena ocheperako pang’ono, mutha kuyesanso kugwiritsa ntchito ma 20 / 8mil vias. Pazomwe zikuchitika pakali pano, ndizovuta kugwiritsa ntchito zing’onozing’ono kudzera m’mabowo (pomwe kuya kwa dzenje kupitirira kasanu ndi kamodzi pakuboola, ndikosatheka kuwonetsetsa kuti khoma la dzenje likhoza kukulungidwa ndi mkuwa); Kwa ma vias a mphamvu kapena nthaka, kukula kwakukulu kumatha kuganiziridwa kuti kuchepetsa kutayika

(2) Kuwongolera mayendedwe pa PCB board sikungasinthe zigawo momwe zingathere, ndiye kuti, ma vias osafunikira sangagwiritsidwe ntchito momwe angathere

(3) Zikhomo zamagetsi ndi nthaka ziyenera kupakidwa pafupi. Kufupikitsa kutsogolera pakati pa kudzera ndi pini, kumakhala bwino

(4) Ikani ma vias ozungulira pafupi ndi ma vias osintha ma siginolo kuti apereke dera loyandikira kwambiri kwa chizindikirocho. Mutha kuyikiranso ma vias ochulukirapo osavomerezeka pa PCB

6. Zina zomwe zimachitika pochepetsa phokoso komanso kusokonekera kwamagetsi

(1) Ngati mutha kugwiritsa ntchito tchipisi totsika kwambiri, simusowa zothamanga kwambiri. Tchipisi othamanga kwambiri amagwiritsidwa ntchito m’malo ofunikira

(2) Zotsutsana zingapo zitha kugwiritsidwa ntchito pochepetsa kulumpha kwapamwamba kumtunda ndi kumunsi kwa dera loyendetsa.

(3) Yesetsani kupereka njira zina zotetezera matayilidwe, ndi zina zotero, monga RC kukhazikitsa damping pakadali pano

(4) Gwiritsani ntchito wotchi yapafupipafupi kwambiri yomwe imakwaniritsa zofunikira zadongosolo.

(5) Wotchiyo izikhala pafupi kwambiri ndi chipangizocho pogwiritsa ntchito wotchiyo. Chigoba cha oscillator cha quartz chikhazikike. Dera la wotchi lizunguliridwa ndi waya wapansi. Chingwe cha wotchi chizikhala chachifupi momwe zingathere. Sipadzakhala kulumikizana pansi pa kristalo wa quartz komanso pansi pa chida chanzeru. Ma siginecha, mabasi ndi ma chip osankha azikhala kutali ndi I / O mzere ndi cholumikizira. Kusokonezedwa kwa mzere wa wotchi molingana ndi mzere wa I / O ndizochepera kuposa kufanana ndi mzere wa I / O

(6) Mapeto olowa a dera losagwiritsidwa ntchito sayenera kuyimitsidwa, malekezero abwino a amplifier osagwiritsidwa ntchito azikhala pansi, ndipo cholowera cholakwika chidzalumikizidwa kumapeto