- 22

- Sep

Ikon sarrafa tsarin sarrafawa don babban Kwamitin PCB

Ikon sarrafa tsarin sarrafawa don Babban Mataki PCB hukumar

Babban allon kewayawa gabaɗaya an bayyana shi azaman katako mai hawa mai hawa-hawa mai hawa 10-20 ko fiye, wanda yafi wahalar aiwatarwa fiye da na gargajiya. katako mai hawa da yawa kuma yana da buƙatun inganci da aminci. An fi amfani da shi a cikin kayan sadarwa, babban sabar uwar garke, kayan aikin likitanci, jirgin sama, sarrafa masana’antu, sojoji da sauran fannoni. A cikin ‘yan shekarun nan, buƙatun kasuwa na manyan allo a fannonin sadarwar aikace-aikacen, tashar tushe, jirgin sama da sojoji har yanzu suna da ƙarfi. Tare da saurin ci gaban kasuwar kayan aikin sadarwa na kasar Sin, fatan kasuwa na manyan allon alfarma yana da kyau.

A halin yanzu, PCB manufacturers wanda zai iya samar da PCB mai tsayi a China galibi ya fito ne daga kamfanonin da ƙasashen waje ke tallafawa ko wasu ƙananan kamfanoni na cikin gida. Samar da PCB mai tsayi yana buƙatar ba kawai fasaha mafi girma da saka hannun jari na kayan aiki ba, har ma da tarin ƙwarewar masu fasaha da ma’aikatan samarwa. A lokaci guda, hanyoyin ba da takardar shaidar abokin ciniki don shigo da PCB mai tsayi suna da tsauri kuma suna da wahala. Sabili da haka, ƙofar PCB mai hawa don shiga kasuwancin yana da girma kuma tsarin samar da masana’antu yana da tsawo. Matsakaicin adadin yadudduka na PCB ya zama muhimmin ma’aunin fasaha don auna matakin fasaha da tsarin samfuran kamfanonin PCB. Wannan takarda a taƙaice ta bayyana manyan matsalolin sarrafawa da aka fuskanta a cikin samar da PCB mai tsayi, kuma yana gabatar da mahimman wuraren sarrafa manyan hanyoyin samar da manyan PCB don yin tunani.

1, Babban matsalolin wahala

Idan aka kwatanta da halayen samfuran kwamiti na al’ada, katako mai hawa mai hawa yana da halayen katako mai kauri, ƙarin yadudduka, layuka masu ɗimbin yawa da vias, girman raka’a mafi girma, Layer dielectric thinner, da tsauraran buƙatun don sararin ciki, jeri na interlayer, sarrafa rashin ƙarfi. da aminci.

Matsaloli 1.1 a jeri na interlayer

Saboda babban adadin yadudduka na katako mai tsayi, ƙarshen ƙirar abokin ciniki yana da ƙarin buƙatu masu tsauri akan daidaiton yadudduka na PCB, kuma juriya jeri tsakanin yadudduka galibi ana sarrafa shi zuwa ± 75 μ m. La’akari da babban ƙimar girman ƙirar babban jirgi, yanayin zazzabi da zafi na bitar canja wurin zane-zane, ƙauracewar yanayi da yanayin saka interlayer wanda ya haifar da rashin daidaituwa da ƙanƙantar da yadudduka na katako daban-daban, yana da wahala a sarrafa mai haɗawa jeri na babban jirgi.

Matsaloli 1.2 a cikin kewaya ciki

Babban jirgin sama yana ɗaukar kayan aiki na musamman kamar babban Tg, babban gudu, madaidaicin mita, jan ƙarfe mai kauri da siket ɗin dielectric, wanda ke gabatar da manyan buƙatu don ƙira da sarrafa girman hoto na kewaye na ciki, kamar amincin siginar rashin ƙarfi. watsawa, wanda ke ƙara wahalar ƙirar ƙirar ciki. Faɗin layin da tazarar layin ƙarami ne, buɗewa da gajerun da’irori suna ƙaruwa, ƙaramin ƙaramin ƙara yana ƙaruwa, kuma ƙimar cancantar ta yi ƙasa kaɗan; Akwai yadudduka sigina da yawa na layuka masu kyau, kuma yuwuwar ɓacewa AOI a cikin rufin ciki yana ƙaruwa; Babban farantin ciki na ciki yana da kauri, yana da sauƙin ninkawa, yana haifar da bayyanar mara kyau, kuma yana da sauƙin mirgina bayan etching; Yawancin allon hawa mai hawa-hawa allon allo ne tare da girman girman naúrar, kuma farashin goge samfuran da aka gama yana da inganci.

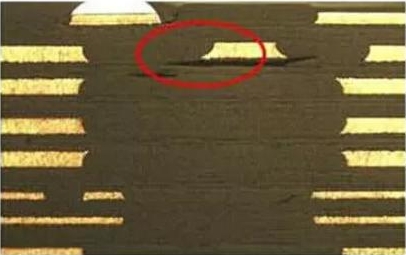

1.3 matsalolin matsin lamba na masana’antu

Lokacin da aka ɗora faranti na ciki da faifai da yawa da aka warkar da su, lahani kamar farantin faifai, delamination, ramin resin da sauran kumfa suna da sauƙin faruwa a cikin samar da shinge. Lokacin zayyana tsarin laminated, ya zama dole a yi la’akari da cikakken juriya na zafi, juriya na ƙarfin lantarki, adadin cika manne da kaurin matsakaici na kayan, da saita shirin matse farantin faranti mai dacewa. Akwai yadudduka da yawa, kuma kula da faɗaɗawa da ƙanƙancewa da biyan diyya na girman ba zai iya zama daidai ba; Layer rufi na interlayer yana da bakin ciki, wanda yake da sauƙin kai ga gazawar gwajin amincin interlayer. Siffa 1 hoto ne na lahani na fashewar farantin fale -falen bayan gwajin danniya na zafi.

Fig.1

1.4 matsalolin hakowa

Amfani da babban Tg, babban gudu, madaidaicin mita da faranti na musamman na jan ƙarfe yana ƙara wahalar hakowa, hakowa burr da hakowa datti. Akwai yadudduka da yawa, jimlar kaurin tagulla da kaurin farantin sun tara, kuma kayan aikin hakowa yana da sauƙin karya; Rashin nasarar CAF ta haifar da BGA mai yawa da tazarar bangon rami mai zurfi; Saboda kaurin farantin, yana da sauƙin haifar da matsalar hakowa.

2, Key samar da tsari sarrafa

2.1 Zaɓin kayan

Tare da haɓaka abubuwan lantarki a cikin jagorancin babban aiki da ayyuka da yawa, yana kuma kawo watsawar siginar mitar sauri da sauri. Sabili da haka, ana buƙatar cewa madaidaiciyar madaidaiciyar wutar lantarki da asarar wutar lantarki na kayan aikin lantarki ba su da ƙarancin ƙarfi, kazalika da ƙarancin CTE, ƙarancin ruwan sha da mafi kyawun kayan aikin laminate na jan ƙarfe, don saduwa da sarrafawa da buƙatun abin dogaro. -tashi allon. Masu ba da farantin gama gari galibi sun haɗa da jerin, jerin B, jerin C da jerin D. Dubi Jigo na 1 don kwatancen manyan halaye na waɗannan ƙananan abubuwa huɗu na ciki. Don katako mai kauri mai kauri na jan ƙarfe, an zaɓi takardar warkarwa mai cike da babban abun ciki. Adadin adadin manne na takaddar warkar da aka warkar da ita ya isa ya cika zane -zane na ciki. Idan insulating matsakaici Layer ne ma lokacin farin ciki, ƙãre jirgin ne mai sauki ya yi yawa kauri. A akasin wannan, idan rufin matsakaici mai ruɓi ya yi ƙanƙara, yana da sauƙi don haifar da matsaloli masu inganci kamar matsakaici madaidaiciya da gazawar gwajin ƙarfin lantarki. Sabili da haka, zaɓin insulating matsakaici kayan yana da matukar muhimmanci.

2.2 zane na laminated tsarin

Babban abubuwan da aka yi la’akari da su a cikin ƙirar ƙirar laminated shine juriya na zafi, juriya na ƙarfin lantarki, adadin cika manne da kaurin kayan abu, kuma za a bi manyan ƙa’idodi masu zuwa.

(1) Mai ƙera takardar warkar da warkarwa da katako dole ne ya kasance daidai. Domin tabbatar da amincin PCB, ba za a yi amfani da takardar warkarwa guda ɗaya ta 1080 ko 106 ba don duk yadudduka na takardar warkarwa (sai dai idan abokin ciniki yana da buƙatu na musamman). Lokacin da abokin ciniki ba shi da buƙatun kauri na matsakaici, matsakaicin kauri tsakanin yadudduka dole ne a tabbatar ya zama ≥ 0.09mm bisa ga ipc-a-600g.

(2) Lokacin da abokan ciniki ke buƙatar babban allo na Tg, babban allon da takardar warkarwa za ta yi amfani da manyan kayan Tg daidai.

(3) Don substrate na ciki 3oz ko sama, zaɓi takardar da aka warke tare da babban abun ciki, kamar 1080r / C65%, 1080hr / C 68%, 106R / C 73%, 106hr / C76%; Koyaya, ƙirar ƙirar dukkan manyan goge -goge na manne 106 waɗanda aka warkar da su za a guji su gwargwadon iko don hana ɗaukar hoto da yawa. Saboda zaren fiber na gilashi ya yi ƙanƙara sosai, yarn fiber ɗin gilashi ya faɗi a cikin babban yanki na ƙasa, wanda ke shafar daidaiton girma da delamination fashewar farantin.

(4) Idan abokin ciniki ba shi da buƙatu na musamman, kaurin haƙuri na Layer dielectric Layer ana sarrafa shi gaba ɗaya + / – 10%. Don farantin impedance, juriya mai kauri mai ƙarfi yana sarrafawa ta juriya ipc-4101 C / M. Idan abubuwan da ke haifar da rashin daidaituwa suna da alaƙa da kaurin substrate, dole ne a sarrafa haƙurin farantin ta ipc-4101 C / M.

2.3 sarrafa interlayer jeri iko

Don daidaiton girman diyya na babban jirgi na ciki da sarrafa girman girma, ya zama dole a rama daidai gwargwadon girman kowane yanki na babban hawa ta hanyar bayanai da ƙwarewar bayanan tarihi da aka tattara a cikin samarwa na wani lokaci don tabbatar da daidaiton faɗaɗawa da ƙanƙancewa na kowane Layer na babban jirgi. Zaɓi madaidaiciyar madaidaiciya kuma amintaccen yanayin sakawa tsakanin interlayer kafin latsa, kamar fil Lam, zafi-narke da haɗin rivet. Kafa hanyoyin aiwatar da matsi da suka dace da kuma kula da jaridu na yau da kullun sune mabuɗin don tabbatar da ingancin matsi, sarrafa manne matsi da tasirin sanyaya, da rage matsalar ɓarkewar interlayer. Ana buƙatar yin la’akari da ikon daidaita daidaiton interlayer daga abubuwa kamar ƙimar diyya ta ciki, yanayin saka matsayi, matsi tsarin aiki, halayen kayan aiki da sauransu.

2.4 Tsarin layin ciki

Saboda ikon nazari na injin watsawa na gargajiya bai wuce 50 μ M. don samar da faranti masu tsayi ba, ana iya gabatar da hoton kai tsaye na laser (LDI) don haɓaka ikon nazarin zane, wanda zai iya kaiwa 20 μ M ko makamancin haka. Daidaitaccen daidaituwa na injin watsawa na gargajiya shine ± 25 μ m. Daidaitaccen daidaiton madaidaiciya ya fi 50 μ m。 Amfani da madaidaicin madaidaiciyar jeri, za a iya inganta daidaiton jadawalin zuwa 15 μ M, daidaitaccen daidaiton daidaituwa mai sarrafa 30 μ M, wanda ke rage karkacewar daidaiton kayan aikin gargajiya da ingantawa. daidaiton daidaiton interlayer na babban dutsen.

Don haɓaka ƙarfin layin layin, ya zama dole a ba da diyya da ta dace don faɗin layin da kushin (ko zoben walda) a cikin ƙirar injiniya, kazalika da ƙarin ƙimar ƙirar ƙira don adadin diyya na musamman zane -zane, kamar layin dawowa da layin mai zaman kansa. Tabbatar ko biyan diyya na faɗin layin ciki, nisan layi, girman zobe kadaici, layi mai zaman kansa da rami zuwa nisan layi daidai ne, in ba haka ba canza ƙirar injiniya. Akwai impedance da inductive reactance zane bukatun. Kula da ko ƙimar ƙirar layin mai zaman kansa da layin rashin ƙarfi ya wadatar. Sarrafa sigogi yayin etching. Za’a iya samar da ƙungiya kawai bayan an tabbatar da yanki na farko ya cancanta. Don rage lalata lalata gefen, ya zama dole a sarrafa abubuwan sunadarai na kowane rukuni na maganin etching a cikin mafi kyawun kewayon. Kayan aikin layin gargajiya na gargajiya ba shi da isasshen damar yin siyarwa. Za’a iya canza kayan aikin ta hanyar fasaha ko shigo da su cikin madaidaicin kayan aikin layin layi don haɓaka daidaiton etching da rage matsaloli kamar ƙaƙƙarfan kaifi da ƙazamar ƙazanta.

2.5 latsa tsari

A halin yanzu, hanyoyin saka interlayer kafin latsa galibi sun haɗa da: pin Lam, narkar da zafi, rivet, da haɗin narkar da zafi. Ana karɓar hanyoyin sakawa daban -daban don tsarin samfuran daban -daban. Don falo mai tsayi, za a yi amfani da hanyar saka ramin huɗu (pin Lam) ko hanyar haɗawa + hanyar riveting. Injin wasan ope zai bugi rami na sakawa, kuma za a sarrafa daidaiton bugun cikin ± 25 μ m。 A lokacin hadawa, za a yi amfani da X-ray don duba karkacewar farantin farantin farko da injin daidaitawa ya yi, da tsari za a iya yin shi kawai bayan karkacewar Layer ya cancanta. A lokacin samar da tsari, ya zama dole a bincika ko an narkar da kowane farantin a cikin naúrar don hana delamination na gaba. Kayan latsawa yana ɗaukar babban goyan bayan goyan baya don saduwa da daidaitaccen daidaitaccen daidaituwa da amincin faranti masu tsayi.

Dangane da tsarin laminated na katako mai hawa da kayan da ake amfani da su, yi nazarin hanyar latsawa da ta dace, saita mafi kyawun ƙimar zazzabi da lanƙwasa, da kyau rage ƙimar hauhawar hauhawar guguwa a cikin tsarin latsawa mai hawa da yawa. tsawaita lokacin warkar da zazzabi mai zafi, sa resin ya cika gudana da ƙarfi, kuma ku guji matsaloli kamar farantin faifai da ɓarkewar interlayer a cikin tsarin dannawa. Faranti masu ƙimar TG daban -daban ba za su zama iri ɗaya da faranti na gira ba; Ba za a iya haɗa faranti tare da sigogi na yau da kullun tare da faranti tare da sigogi na musamman ba; Don tabbatar da sahihancin faɗaɗawar da aka bayar da ƙuntatawa, kaddarorin faranti daban -daban da fakitin warkarwa daban -daban, don haka ana buƙatar latsa madaidaicin farantin da aka warkar da sigogi, kuma ana buƙatar tabbatar da sigogin tsari don kayan musamman waɗanda ke da ba a taɓa amfani da shi ba.

2.6 tsarin hakowa

Saboda kaurin farantin farantin da murfin jan ƙarfe wanda ya haifar da babban juzu’i na kowane Layer, raunin raunin yana sawa sosai kuma yana da sauƙin karya bitar. Yawan ramuka, saurin faɗuwa da saurin juyawa za a rage yadda ya dace. Daidaitaccen faɗaɗa faɗaɗa da ƙanƙancewar farantin don samar da daidaitaccen daidaituwa; Idan adadin yadudduka ≥ 14, ramin rami ≤ 0.2mm ko nisa daga rami zuwa layi ≤ 0.175mm, injin hakowa tare da daidaiton matsayin rami ≤ 0.025mm za a yi amfani da shi don samarwa; diamita diameter Ramin ramin da ke sama da 4.0mm yana ɗaukar hakowa mataki-mataki, kuma kaurin diamita shine 12: 1. Ana samar da shi ta hanyar hakowa mataki-mataki da hakowa mai kyau da mara kyau; Sarrafa burur da kaurin ramin hakowa. Za a haƙa dutsen mai tsayi da sabon wuka ko wuka mai niƙa kamar yadda zai yiwu, kuma za a sarrafa kaurin ramin a cikin 25um. Don haɓaka matsalar hakowa na farantin ƙarfe mai kauri mai ƙarfi, ta hanyar tabbatar da tsari, amfani da farantin goyan baya mai yawa, adadin faranti da aka ƙera ɗaya ne, kuma ana sarrafa lokutan niƙa na bitar cikin sau 3, wanda zai iya inganta burr hakowa yadda yakamata

Don katako mai hawa mai amfani mita-yawa, babban sauri da watsa bayanai masu yawa, fasahar hakowa ta baya hanya ce mai inganci don haɓaka amincin sigina. Hakowa na baya galibi yana sarrafa tsawon tsutsa, ragowar matsayin ramin rijiyoyin biyu da waya na jan ƙarfe a cikin ramin. Ba duk kayan aikin injin hakowa suna da aikin hakowa na baya ba, don haka ya zama dole haɓaka kayan aikin injin hakowa (tare da aikin hakowa na baya) ko siyan injin hakowa tare da aikin hakowa na baya. Fasahar hakowa ta baya da aka yi amfani da ita daga wallafe -wallafen da suka shafi masana’antu da samar da balaguro da yawa sun haɗa da: sarrafa zurfin sarrafawa ta hanyar hakowa ta baya, hakowa ta baya tare da layin amsa sigina a cikin sashin ciki, da lissafin zurfin hakowa gwargwadon gwargwadon kaurin farantin. Ba za a maimaita shi a nan ba.

3 test Gwajin dogaro

Babban jirgin sama gabaɗaya farantin tsarin ne, wanda ya yi kauri da nauyi fiye da farantin farantin fa’ida mai yawa, yana da girman raka’a mafi girma, kuma ƙarfin zafin da ya dace shima ya fi girma. A lokacin walda, ana buƙatar ƙarin zafi kuma lokacin walda babban zafin jiki yana da tsawo. A 217 ℃ (wurin narkewa na tin azurfa na jan ƙarfe), yana ɗaukar daƙiƙa 50 zuwa daƙiƙa 90. A lokaci guda, saurin sanyaya babban farantin farantin yana da ɗan jinkiri, don haka lokacin gwajin reflow ya tsawanta. Haɗe tare da ipc-6012c, ƙimar IPC-TM-650 da buƙatun masana’antu, ana aiwatar da babban gwajin dogaro na babban jirgi.