- 22

- Sep

Cov txheej txheem tsim khoom tseem ceeb rau Qib Siab PCB board

Kev tsim cov txheej txheem tseem ceeb rau Qib Siab PCB Rooj Tswjhwm Saib cov

Cov rooj sib tham hauv Circuit Court siab yog feem ntau txhais tau tias yog cov rooj sib tham ntau txheej txheej nrog 10-20 plag lossis ntau dua, uas nyuaj rau txheej txheem ntau dua li ib txwm muaj multi-txheej Circuit Court board thiab muaj qhov ua tau zoo thiab ntseeg tau. Nws feem ntau yog siv hauv cov cuab yeej sib txuas lus, cov neeg siv khoom siv siab, khoom siv kho mob, kev ya dav hlau, kev tswj hwm kev lag luam, tub rog thiab lwm yam haujlwm. Xyoo tsis ntev los no, kev thov kev lag luam rau cov laug cam siab nyob hauv thaj tsam ntawm daim ntawv thov kev sib txuas lus, chaw nres tsheb hauv paus, kev tsav dav hlau thiab tub rog tseem muaj zog. Nrog kev txhim kho sai ntawm Tuam Tshoj cov cuab yeej siv khoom lag luam kev lag luam, kev cia siab ntawm kev lag luam ntawm cov laug cam siab tau cog lus.

Tam sim no, PCB chaw tsim tshuaj pauss uas tuaj yeem tsim cov PCB siab hauv Suav teb feem ntau yog los ntawm cov tuam txhab lag luam txawv teb chaws lossis ob peb lub tsev lag luam. Kev tsim cov PCB siab yuav tsum tsis yog siv thev naus laus zis thiab khoom siv peev txheej ntau dua, tab sis kuj tseem muaj kev paub dhau los ntawm cov kws tshaj lij thiab cov neeg ua haujlwm tsim khoom. Nyob rau tib lub sijhawm, cov txheej txheem kev lees paub cov neeg siv khoom rau kev nkag siab PCB siab yog nruj thiab tsis yooj yim. Yog li ntawd, lub hauv paus rau kev nce qib PCB kom nkag mus rau lub tuam txhab tau siab thiab kev tsim khoom lag luam mus los ntev. Tus naj npawb nruab nrab ntawm txheej txheej PCB tau dhau los ua qhov ntsuas ntsuas tseem ceeb txhawm rau ntsuas cov txheej txheem thiab cov khoom lag luam ntawm PCB cov tuam txhab. Daim ntawv no piav qhia luv luv piav qhia txog cov teeb meem tseem ceeb uas tau ntsib hauv kev tsim cov PCB siab, thiab qhia cov ntsiab lus tswj hwm ntawm cov txheej txheem tseem ceeb ntawm kev ua haujlwm siab PCB rau koj siv.

1, Cov teeb meem tsim khoom loj

Piv nrog rau cov yam ntxwv ntawm cov khoom lag luam hauv Circuit Court, cov khoom siv hluav taws xob siab muaj cov yam ntxwv ntawm cov laug cam tuab dua, txheej ntau dua, kab tuab thiab vias, qhov loj dua ntawm chav nyob, txheej dielectric thinner, thiab qhov xav tau nruj rau qhov chaw sab hauv, kev sib koom ua ke, kev tiv thaiv kev tiv thaiv thiab kev ntseeg tau

1.1 teeb meem hauv kev sib koom ua ke sib cuam tshuam

Vim tias muaj coob tus txheej txheem txheej txheem txheej txheem siab, cov neeg siv khoom tsim qhov kawg tau muaj qhov xav tau nruj ntawm kev ua kom sib luag ntawm PCB txheej, thiab kev ua siab ntev ua ke ntawm cov txheej txheem feem ntau tswj tau rau ± 75 μ m. Xav txog qhov loj chav tsim qauv ntawm lub rooj tsav xwm siab, qhov kub thiab txias ntawm cov duab hloov pauv rhiav, qhov kev txav chaw tsis sib xws thiab kev sib cuam tshuam ntawm qhov chaw sib koom ua ke tshwm sim los ntawm kev tsis sib xws nthuav dav thiab kev sib cais ntawm cov tub ntxhais sib txawv txheej txheem, nws nyuaj dua los tswj cov interlayer kev sib koom ua ke ntawm pawg thawj coj siab.

1.2 teeb meem hauv kev tsim sab hauv

Lub rooj tsav xwm siab tau txais cov ntaub ntawv tshwj xeeb xws li Tg siab, kev kub ceev, ntau zaus, tuab tooj liab thiab txheej txheej dielectric, uas tso rau pem hauv ntej cov kev xav tau rau kev tsim thiab teeb duab loj tswj ntawm sab hauv Circuit Court, xws li kev ncaj ncees ntawm kev cuam tshuam lub teeb liab kis tau tus mob, uas nce qhov nyuaj ntawm kev tsim cov khoom siv sab hauv. Cov kab dav thiab kab sib nrug me me, qhib thiab luv Circuit Court nce, qhov luv luv micro nce, thiab tus nqi tsim nyog tau qis; Muaj ntau lub teeb liab txheej ntawm cov kab zoo, thiab qhov tshwm sim ntawm ploj AOI nrhiav pom hauv txheej txheej sab hauv nce; Cov phaj sab hauv yog nyias, yooj yim quav, ua rau tsis zoo, thiab nws yooj yim rau yob tom qab kos; Feem ntau ntawm cov rooj zaum siab yog cov laug cam nrog cov chav loj, thiab tus nqi ntawm kev muab cov khoom tiav yog qhov siab.

1.3 nias nyuaj tsim khoom

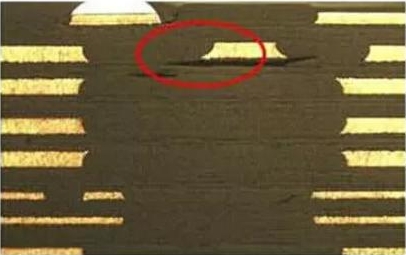

Thaum ntau daim hlau sab hauv thiab cov ntawv kho ib nrab tau ua ntau dhau, qhov tsis xws xws li cov phaj zawv zawg, kev tshem tawm, cov kab noj hniav thiab cov npuas uas seem tau yooj yim tshwm sim hauv kev tsim khoom. Thaum tsim cov txheej txheem laminated, nws yog qhov tsim nyog yuav tsum tau txiav txim siab txog kev tiv thaiv tshav kub, tiv thaiv hluav taws xob, kua nplaum ntim cov nyiaj thiab cov tuab tuab nruab nrab ntawm cov khoom, thiab teeb tsa qhov tsim nyog ua kom siab phaj nias qhov program. Muaj ntau txheej, thiab kev tswj hwm ntawm kev nthuav dav thiab kev cog lus thiab kev them nyiaj ntawm qhov loj me coefficient tsis tuaj yeem sib xws; Cov txheej txheej rwb thaiv tsev interlayer yog nyias, uas yog ib qho yooj yim mus rau qhov ua tsis tiav ntawm kev sib tw kev ntseeg siab. Daim duab 1 yog daim duab qhia txog qhov tsis xws luag ntawm cov phaj tawg tom qab ntsuas cua sov.

Daim duab XYUMX

1.4 qhov teeb meem drilling

Kev siv Tg siab, kev kub ceev, kev siv ntau zaus thiab tuab cov phaj tooj liab tshwj xeeb ua rau qhov nyuaj ntawm kev ntxhib ntxhib, kev khawb av thiab kev tshem cov av tshem tawm. Muaj ntau txheej, tag nrho cov tooj liab tuab thiab phaj tuab tau sib sau ua ke, thiab cov cuab yeej ua kom tawg tau yooj yim; Caf tsis ua haujlwm los ntawm ntom BGA thiab qhov nqaim ntawm phab ntsa sib nrug; Vim lub phaj tuab, nws yooj yim ua rau muaj teeb meem ntawm oblique drilling.

2, Kev tswj cov txheej txheem tseem ceeb

2.1 xaiv cov khoom

Nrog rau kev txhim kho cov khoom siv hluav taws xob hauv kev coj ua kom muaj txiaj ntsig zoo thiab ua haujlwm tau zoo, nws kuj tseem nqa cov khoom siv hluav taws xob ntau thiab nrawm. Yog li ntawd, nws xav tau tias dielectric tsis tu ncua thiab dielectric poob ntawm cov khoom siv hluav taws xob hluav taws xob kuj tsawg, nrog rau CTE qis, nqus dej tsawg thiab ua tau zoo dua tooj liab clad laminate cov ntaub ntawv, thiaj li ua tau raws li kev ua thiab kev ntseeg siab xav tau ntawm siab -sawv cov laug cam. Cov phaj khoom siv feem ntau suav nrog koob, B series, C series thiab D series. Saib Cov Lus 1 rau kev sib piv ntawm cov yam ntxwv tseem ceeb ntawm plaub lub hauv qab no. Rau lub siab ua kom tuab cov tooj liab Circuit Court board, cov ntawv kho ib nrab nrog cov ntsiab lus siab cob yog xaiv. Cov kua nplaum ntws ntawm cov txheej txheej ib nrab kho cov ntawv yog txaus los sau cov duab sab hauv. Yog tias txheej txheej nruab nrab insulating yog tuab dhau, daim ntawv ua tiav yog yooj yim kom tuab dhau. Ntawm qhov tsis sib xws, yog tias txheej txheej nruab nrab insulating yog nyias dhau, nws yooj yim ua rau muaj teeb meem zoo xws li nruab nrab stratification thiab qhov ntsuas hluav taws xob siab ua tsis tiav. Yog li ntawd, xaiv cov ntaub ntawv insulating nruab nrab yog qhov tseem ceeb heev.

2.2 tsim cov qauv laminated

Lub hauv paus tseem ceeb tau txiav txim siab hauv kev tsim cov txheej txheem laminated yog kev tiv thaiv tshav kub, tiv thaiv hluav taws xob, kua nplaum ntim thiab dielectric txheej tuab ntawm cov khoom, thiab cov hauv paus ntsiab lus hauv qab no yuav tsum ua raws.

(1) Cov chaw tsim khoom ntawm cov ntawv kho ib nrab thiab cov laug cam yuav tsum zoo ib yam. Txhawm rau kom ntseeg tau tias muaj kev ntseeg siab ntawm PCB, ib qho 1080 lossis 106 daim ntawv kho ib nrab yuav tsum tsis siv rau txhua txheej ntawm ib nrab ntawv kho (tshwj tsis yog cov neeg siv khoom tshwj xeeb xav tau). Thaum cov neeg siv khoom tsis muaj qhov xav tau tuab nruab nrab, qhov nruab nrab tuab ntawm txheej yuav tsum tau lees tias yog ≥ 0.09mm raws li ipc-a-600g.

(2) Thaum cov neeg siv khoom xav tau Tg pawg thawj coj siab, pawg thawj coj saib xyuas thiab cov ntawv kho ib nrab yuav tsum siv cov khoom Tg siab sib xws.

(3) Rau sab hauv txheej 3oz lossis siab dua, xaiv cov ntawv kho ib nrab uas muaj cov ntsiab lus siab, xws li 1080r / C65%, 1080hr / C 68%, 106R / C 73%, 106hr / C76%; Txawm li cas los xij, kev tsim qauv ntawm tag nrho 106 cov kua nplaum ib nrab kho cov ntawv yuav tsum raug zam kom deb li deb tau kom tiv thaiv qhov tsis sib xws ntawm ntau yam 106 cov ntawv kho ib nrab. Vim tias cov iav fiber ntau yog nyias dhau, iav iav xov paj tau tawg hauv thaj chaw loj, uas cuam tshuam rau qhov ruaj ntseg ntawm sab nrauv thiab phaj tawg tawg.

(4) Yog tias tus neeg siv khoom tsis muaj qhov tshwj xeeb xav tau, kev ua siab tuab ntawm txheej txheej txheej dielectric feem ntau tswj tau los ntawm + / – 10%. Rau cov phaj tsis muaj zog, dielectric thickness kam rau ua yog tswj los ntawm ipc-4101 C / M kam rau ua. Yog tias qhov cuam tshuam cuam tshuam cuam tshuam cuam tshuam nrog cov tuab tuab, cov phaj siab yuav tsum tau tswj los ntawm ipc-4101 C / M kam rau ua.

2.3 interlayer kawm tuab si lug tswj

Txog qhov raug ntawm lub hauv paus pawg thawj coj saib xyuas qhov nyiaj them poob haujlwm thiab kev tsim khoom tsim khoom loj, nws yog qhov tsim nyog los txhawm rau txhawm rau txhawm rau txhawm rau cov duab loj ntawm txhua txheej ntawm pawg thawj coj siab dhau los ntawm cov ntaub ntawv thiab keeb kwm cov ntaub ntawv keeb kwm tau sau hauv kev tsim khoom rau qee lub sijhawm kom ntseeg tau tias muaj qhov sib xws ntawm nthuav dav thiab txo qis ntawm txhua txheej ntawm pawg thawj coj saib. Xaiv high-precision thiab txhim khu kev qha interlayer positioning hom ua ntej nias, xws li tus pin Lam, kub-yaj thiab rivet ua ke. Teeb tsa cov txheej txheem txheej txheem tsim nyog thiab kev saib xyuas txhua hnub ntawm cov xovxwm yog qhov tseem ceeb los xyuas kom muaj kev nias zoo, tswj cov kua nplaum thiab ua kom txias, thiab txo qhov teeb meem ntawm interlayer dislocation. Kev tswj hwm ntawm kev sib koom ua ke yuav tsum tau txiav txim siab los ntawm cov hauv paus ntsiab lus xws li cov txheej txheem txheej txheej sab hauv, nias hom tso rau, nias txheej txheem txheej txheem, cov yam ntxwv khoom thiab lwm yam.

2.4 txheej txheem txheej txheem sab hauv

Vim tias kev tshuaj xyuas lub peev xwm ntawm lub tshuab tso tawm ib txwm muaj tsawg dua 50 μ M. rau kev tsim cov phaj siab, cov duab laser ncaj qha (LDI) tuaj yeem nkag tau los txhim kho lub peev xwm txheeb xyuas cov duab, uas tuaj yeem mus txog 20 μ M lossis li ntawd. Qhov ua kom raug qhov tseeb ntawm cov tshuab ib txwm raug yog ± 25 μ m. Cov txheej txheej sib dhos raug qhov tseeb yog ntau dua 50 μ m。 Siv cov cuab yeej ua kom raug siab raws lub tshuab, cov duab sib dhos raug tuaj yeem txhim kho mus rau 15 μ M, kev sib koom ua ke sib dhos kom raug tswj 30 μ M, uas txo cov kev sib txuam sib txawv ntawm cov cuab yeej ib txwm muaj thiab txhim kho interlayer tuab si lug qhov tseeb ntawm high-rise slab.

Txhawm rau txhawm rau txhim kho cov peev txheej ntawm kab, nws yog qhov tsim nyog yuav tsum tau them nyiaj tsim nyog rau qhov dav ntawm kab thiab lub ncoo (lossis lub nplhaib sib txuas) hauv kev tsim qauv siv tshuab, ntxiv rau kev tsim qauv ntxaws ntxiv rau kev them nyiaj tshwj xeeb cov duab, xws li kab rov qab thiab kab ywj pheej. Txheeb xyuas seb puas tsim cov nyiaj them ntawm cov kab sab hauv dav, kab nrug, cais lub nplhaib loj, kab ywj siab thiab qhov rau kab nrug yog qhov tsim nyog, txwv tsis pub hloov cov qauv tsim qauv. Muaj impedance thiab inductive reactance tsim kom tau. Ua tib zoo saib seb puas tsim kev them nyiaj ntawm txoj kab ywj pheej thiab kab cuam tshuam tsis txaus. Tswj tsis thaum lub sij hawm etching. Kev tsim khoom ntau tuaj yeem nqa tawm tsuas yog tom qab thawj daim ntawv lees paub tias tsim nyog. Txhawm rau txhawm rau txo cov etching sab corrosion, nws yog qhov tsim nyog los tswj cov tshuaj lom neeg muaj pes tsawg leeg ntawm txhua pab pawg ntawm kev daws teeb meem hauv qhov zoo tshaj plaws. Cov cuab yeej siv kab kos ib txwm muaj tsis txaus peev txheej. Cov cuab yeej tuaj yeem hloov pauv lossis hloov pauv mus rau cov cuab yeej siv cov txheej txheem kom zoo los txhim kho cov cim sib xws thiab txo cov teeb meem xws li ntug ntxhib thiab tsis huv.

2.5 txheej txheem nias

Tam sim no, cov txheej txheem txheej txheej txheej ua ntej nias feem ntau suav nrog: tus pin Lam, kub yaj, rivet, thiab ua ke ntawm cov kub yaj thiab rivet. Txoj hauv kev sib txawv ntawm txoj haujlwm tau txais yuav rau cov khoom sib txawv. Txog rau qhov siab nce siab, yuav tsum siv plaub txoj hauv kev (tus pin Lam) lossis fusion + riveting method yuav tsum siv. Lub tshuab xuas nrig ntaus yuav tsum xuas qhov tso rau qhov, thiab qhov xuas nrig ntaus qhov raug yuav tsum tau tswj tsis pub dhau ± 25 μ m。 Thaum sib xyaw, X-ray yuav tsum siv los txheeb xyuas cov txheej txheej ntawm thawj phaj ua los ntawm lub tshuab kho, thiab tuaj yeem ua tau tsuas yog tom qab txheej txheej sib txawv tsim nyog. Thaum lub sijhawm tsim khoom, nws yog qhov tsim nyog los xyuas seb txhua lub phaj tau yaj rau hauv chav los tiv thaiv kev puas tsuaj tom ntej. Cov cuab yeej nias tau txais kev ua haujlwm siab txhawb nqa nias kom tau raws li cov txheej txheej txheej txheej kom raug thiab ntseeg tau ntawm cov phaj siab.

Raws li cov txheej txheem laminated ntawm lub rooj tsav xwm siab thiab cov khoom siv, kawm txog cov txheej txheem tsim nyog, teeb tsa qhov kub zoo tshaj plaws nce thiab nkhaus, tsim nyog txo qhov ntsuas kub nce ntawm nias pawg thawj coj hauv txheej txheej txheej txheej txheej txheem nias, ncua lub sijhawm kub kom kub kom ntau, ua kom cov kua ntws tawm thiab ua kom khov, thiab zam cov teeb meem xws li cov phaj zawv zawg thiab cov neeg sib cuam tshuam hauv kev txav mus los. Cov phaj nrog TG qhov sib txawv qhov sib txawv tsis tuaj yeem zoo ib yam li cov tais diav; Cov phaj uas tsis zoo ib yam tsis tuaj yeem sib xyaw nrog cov phaj nrog cov ntsuas tshwj xeeb; Txhawm rau kom ntseeg tau qhov tseeb ntawm qhov muab nthuav dav thiab txo qis coefficient, cov yam ntxwv ntawm cov phaj sib txawv thiab cov ntawv kho ib nrab yog qhov sib txawv, yog li cov phaj sib thooj ib nrab kho cov ntawv tsis tau yuav tsum tau nias, thiab cov txheej txheem tsis xav tau los txheeb xyuas cov ntaub ntawv tshwj xeeb uas muaj yeej tsis tau siv.

2.6 txheej txheem drilling

Vim tias cov tuab tuab ntawm cov phaj thiab cov tooj liab txheej tshwm sim los ntawm kev hloov pauv ntawm txhua txheej, qhov siv me ntsis tau hnyav hnyav thiab nws yooj yim los tsoo qhov me ntsis. Tus naj npawb ntawm qhov, poob nrawm thiab tig nrawm yuav tsum raug txo kom tsim nyog. Ntsuas ntsuas qhov nthuav dav thiab txo qis ntawm cov phaj kom muab cov coefficient raug; Yog tias muaj pes tsawg txheej ≥ 14, lub qhov taub ≤ 0.2mm lossis qhov deb ntawm qhov rau kab ≤ 0.175mm, qhov drilling rig nrog qhov chaw raug qhov tseeb ≤ 0.025mm yuav tsum siv rau kev tsim khoom; txoj kab uas hla: Lub qhov taub siab dua 4.0mm txais yuav cov cuab yeej ib qib zuj zus, thiab qhov tuab tuab piv yog 12: 1. Nws yog tsim los ntawm kev nqis tes ua ib theem zuj zus thiab qhov zoo thiab qhov tsis zoo drilling; Tswj cov burr thiab qhov tuab ntawm qhov drilling. Cov nplais pob zeb siab yuav tsum tau hlais nrog rab riam tshiab lossis rab riam sib tsoo kom deb li deb tau, thiab qhov tuab yuav tsum tau tswj tsis pub dhau 25um. Txhawm rau txhawm rau txhim kho qhov teeb meem khawb khawb ntawm cov phaj tuab tuab tuab, los ntawm cov ntawv pov thawj, kev siv cov ntaub ntawv thim rov qab siab, cov phaj laminated yog ib qho, thiab lub sijhawm sib tsoo ntawm kev siv me ntsis raug tswj tsis pub dhau 3 zaug, uas tuaj yeem txhim kho qhov drilling burr

Rau lub rooj tsavxwm siab siv rau high-zaus, kev kub ceev thiab cov ntaub ntawv sib kis loj heev, thim rov qab thev naus laus zis yog txoj hauv kev zoo los txhim kho teeb liab kev ntseeg. Lub nraub qaum feem ntau tswj hwm qhov seem ntev ntev, qhov chaw sib xws ntawm ob lub qhov dej thiab cov tooj liab hauv lub qhov. Tsis yog txhua qhov cuab yeej siv tshuab tau rov ua haujlwm rov qab, yog li nws yog qhov yuav tsum tau hloov kho cov cuab yeej siv lub tshuab drilling (nrog rov ua haujlwm rov qab) lossis yuav lub tshuab drilling nrog rov ua haujlwm. Sab nraub qaum thev naus laus zis siv los ntawm kev lag luam cuam tshuam nrog cov ntaub ntawv thiab paub tab loj ntau lawm suav nrog: tsoos qhov tob tswj rov qab drilling txoj kev, rov qab drilling nrog teeb liab tawm tswv yim txheej hauv txheej sab hauv, thiab suav qhov tob rov qab drilling raws li kev faib ua feem ntawm phaj tuab. Nws yuav tsis rov hais dua ntawm no.

3 test Kev ntsuas kev ntseeg siab

Lub rooj tsav tsheb siab yog feem ntau yog cov phaj system, uas yog tuab dua thiab hnyav dua li cov phaj ntau txheej txheej, muaj chav loj dua, thiab qhov muaj peev xwm ua kom sov kuj tseem loj dua. Thaum lub sijhawm siv vuam, yuav tsum muaj cua sov ntau dua thiab lub sijhawm vuam kub yog ntev. Ntawm 217 ℃ (cov ntsiab lus melting ntawm tin silver tooj liab solder), nws siv sijhawm 50 vib nas this txog 90 vib nas this. Nyob rau tib lub sijhawm, qhov txias txias ntawm cov phaj siab yog qhov qeeb, yog li lub sijhawm ntsuas qhov ntsuas rov ua dua. Ua ke nrog ipc-6012c, IPC-TM-650 cov qauv thiab cov kev xav tau hauv kev lag luam, kev ntsuas kev ntseeg siab ntawm lub rooj tsav xwm siab tau ua tiav.