- 22

- Sep

Inqubo yokukhiqiza inqubo yokulawula yebhodi ephezulu ye-PCB

Ukulawulwa kwenqubo yokukhiqiza kwezinga eliphakeme PCB ibhodi

Ibhodi lesifunda eliphakeme kakhulu livame ukuchazwa njengebhodi lesifunda elenzelwa phezulu elinama-10-20 phansi noma ngaphezulu, okunzima kakhulu ukucubungula kunokwesiko multi-ungqimba wesifunda ibhodi futhi inezidingo ezisezingeni eliphakeme nezithembekile. Isetshenziswa kakhulu kwimishini yokuxhumana, iseva esezingeni eliphakeme, i-elektroniki yezokwelapha, ukundiza, ukulawula izimboni, ezempi neminye imikhakha. Eminyakeni yamuva nje, ukufuneka kwemakethe yamabhodi aphakeme emkhakheni wezokuxhumana kwezicelo, isiteshi sesisekelo, ezokundiza nezempi kusenamandla. Ngokuthuthuka okusheshayo kwemakethe yezinsizakusebenza ze-China, ithemba lemakethe lamabhodi aphezulu likuthembisa.

Okwamanje, Umakhi we-PCBs ekwazi ukukhiqiza ngobuningi i-PCB ephezulu eChina ikakhulu ivela kumabhizinisi axhaswa ngezimali angaphandle noma kumabhizinisi ambalwa asekhaya. Ukukhiqizwa kwe-PCB ephezulu akudingi kuphela utshalomali lobuchwepheshe kanye nemishini, kepha futhi nesipiliyoni sokuqongelelwa kochwepheshe nabasebenzi bokukhiqiza. Ngasikhathi sinye, izinqubo zokuqinisekiswa kwamakhasimende zokungenisa i-PCB ephezulu zikhuni futhi zinzima. Ngakho-ke, umkhawulo we-PCB ephezulu yokungena ebhizinisini uphakeme futhi nomjikelezo wokukhiqizwa kwezimboni mude. Inani elijwayelekile lezendlalelo ze-PCB selibe yinkomba yezobuchwepheshe ebalulekile ukukala izinga lobuchwepheshe kanye nesakhiwo somkhiqizo wamabhizinisi e-PCB. Leli phepha lichaza kafushane ubunzima bokucubungula obuhlangabezane nabo ekukhiqizeni i-PCB ephezulu, futhi yethula amaphuzu wokulawula asemqoka wezinqubo zokhiye zokukhiqiza ze-PCB ephezulu yokuthola inkomba yakho.

1, Main ukukhiqizwa nobunzima

Uma kuqhathaniswa nezici zemikhiqizo ejwayelekile yebhodi lesifunda, ibhodi lesifunda eliphakeme linezimpawu zamabhodi amakhulu, izingqimba eziningi, imigqa eqinile kanye nama-vias, usayizi omkhulu weyunithi, ungqimba lwe-dielectric encane, nezidingo eziqinile zesikhala sangaphakathi, ukuqondanisa kwabadlali, ukulawula impedance nokwethembeka.

1.1 ubunzima bokuqondaniswa kwe-interlayer

Ngenxa yenani elikhulu lezendlalelo zebhodi eliphakeme, ukuphela kwekhasimende kunezidingo eziqinile ngokuqondiswa kwezendlalelo ze-PCB, futhi ukubekezelelana kokuqondanisa phakathi kwezendlalelo kuvame ukulawulwa ku-± 75 μ m. Uma ucabanga ngomklamo omkhulu wosayizi wamayunithi webhodi eliphakeme kakhulu, izinga lokushisa eliseduze nomswakama weworkshop yokudlulisa ihluzo, imo yokubeka indawo kanye nemodi yokubeka indawo yabadlali ebangelwe ukwanda okungahambelani nokuncipha kwezendlalelo zamabhodi ahlukahlukene, kunzima kakhulu ukulawula i-interlayer ukuqondanisa kwebhodi eliphakeme.

1.2 ubunzima ekwenzeni isekethe elingaphakathi

Ibhodi eliphakeme lisebenzisa izinto ezikhethekile ezifana ne-Tg ephezulu, isivinini esikhulu, imvamisa ephezulu, ithusi elijiyile nongqimba oluncane lwe-dielectric, olubeka phambili izidingo eziphakeme zokwenziwa nokulawulwa kosayizi wengcaca wesifunda sangaphakathi, njengokuthembeka kwesiginali se-impedance ukudluliswa, okwandisa ubunzima bokuqanjwa kwesekethe langaphakathi. Ububanzi bomugqa nokuhlukaniswa kwemigqa kuncane, amasekethe avulekile futhi amafushane ayakhula, ukunyuka okuncane okuncane, nezinga leziqu liphansi; Kunezingqimba eziningi zesiginali zemigqa emihle, futhi amathuba okuthola i-AOI elahlekile kusendlalelo sangaphakathi ayanda; Ingcwecwe yangaphakathi yomzimba mncane, kulula ukugoqeka, okuholela ekuvezeni okungekuhle, futhi kulula ukugoqa ngemuva kokuthanjiswa; Iningi lamabhodi aphakama kakhulu angamabhodi wesistimu anobukhulu beyunithi enkulu, futhi izindleko zokususa imikhiqizo eqediwe ziphakeme kakhulu.

1.3 ukucindezela ubunzima bokukhiqiza

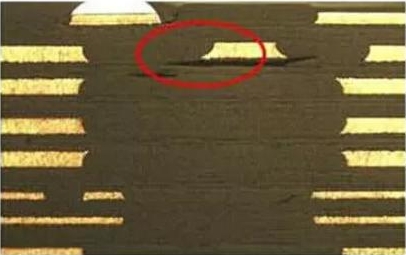

Lapho kuphakanyiswe amapuleti amaningi wangaphakathi wangaphakathi namashidi aphulukisiwe amancane, ukukhubazeka okufana nokwehla kwepuleti, i-delamination, i-resin cavity kanye nezinsalela ze-bubble kulula ukwenzeka ekukhiqizeni i-crimping. Lapho kuklanywa isakhiwo esinamaminerali, kuyadingeka ukuthi ubheke ngokuphelele ukumelana nokushisa, ukumelana namandla kagesi, inani lokugcwalisa iglu nobukhulu obuphakathi kwento, bese usetha uhlelo lokucindezela ipuleti eliphakeme elifanele. Kunezendlalelo eziningi, futhi ukulawulwa kokunwetshwa nokuncipha kanye nesinxephezelo sobukhulu bokulingana ngeke kuhambisane; Isendlalelo se-interlayer insulation sincane, okulula ukuholela ekwehlulekeni kokuhlolwa kokuthembeka kwe-interlayer. Umdwebo 1 umdwebo wesici sokuqhekeka kwepuleti eliqhumayo ngemuva kokuhlolwa kwengcindezi yokushisa.

I-Fig.1

1.4 ubunzima bokubhola

Ukusetshenziswa kwe-Tg ephezulu, isivinini esikhulu, imvamisa ephezulu kanye nensimbi enkulu yamapuleti akhethekile kwenyusa ubunzima bokumba ubukhali, ukubhola i-burr nokususa ukususwa kwenhlabathi. Kukhona izingqimba eziningi, inani lethusi eliphelele nokushuba kwepuleti kunqwabelene, futhi ithuluzi lokubhola kulula ukuliphula; Ukwehluleka kweCaf okubangelwe yi-BGA eminyene kanye nesikhala semigodi emincane emincane; Ngenxa yokuqina kwepuleti, kulula ukudala inkinga yokubhola kwe-oblique.

2, Key inqubo yokukhiqiza control

2.1 ukukhethwa kwezinto ezibonakalayo

Ngokuthuthukiswa kwezakhi ze-elekthronikhi ngokuya ekusebenzeni okuphezulu nasekusebenzeni okuningi, kubuye kulethe ukudluliswa kwesiginali ephezulu kakhulu nesheshayo. Ngakho-ke, kuyadingeka ukuthi ukulahleka kwe-dielectric njalo nokulahlwa kwe-dielectric kwezinto zesekethe ze-elekthronikhi kuphansi kakhulu, kanye ne-CTE ephansi, ukumuncwa kwamanzi okuphansi kanye nokusebenza okungcono kakhulu kokusebenza kwempahla yethusi egqoke i-laminate, ukuze kuhlangatshezwane nezidingo zokucubungula nokwethembeka eziphezulu -phakamisa amabhodi. Abahlinzeki bepuleti abajwayelekile ikakhulukazi bafaka uchungechunge, uchungechunge lwe-B, uchungechunge lwe-C nochungechunge lwe-D. Bona Ithebula 1 ngokuqhathanisa izici eziyinhloko zalezi zingxenye ezine zangaphakathi. Kwibhodi lesifunda lethusi eliphakeme kakhulu, kukhethwa ishidi eliphilisiwe elinokuqukethwe okuphezulu kwe-resin. Inani lokugeleza kweglu leshidi elingaphakathi eliphilisiwe langaphakathi lanele ukugcwalisa ihluzo zangaphakathi zesendlalelo. Uma ungqimba oluvikelayo olumaphakathi lukhulu kakhulu, ibhodi eliqediwe kulula ukuba likhulu kakhulu. Ngokuphambene nalokho, uma ungqimba oluvikelayo oluphakathi luncane kakhulu, kulula ukudala izinkinga zekhwalithi njengokuklwebha okuphakathi nokwehluleka kokuhlolwa kwamandla amakhulu. Ngakho-ke, ukukhethwa kwezinto zokuvikela eziphakathi nendawo kubaluleke kakhulu.

2.2 ukwakheka kwesakhiwo esinamaminerali

Izici eziyinhloko ezicatshangelwe ekwakhiweni kwesakhiwo esine-laminated ukumelana nokushisa, ukumelana namandla kagesi, inani lokugcwalisa i-glue nobukhulu besendlalelo se-dielectric, futhi kuzolandelwa lezi zimiso eziyinhloko ezilandelayo.

(1) Umkhiqizi weshidi eliphilisiwe elincane nebhodi eliyinhloko kufanele lihambisane. Ukuze kuqinisekiswe ukwethembeka kwe-PCB, ishidi elilodwa eliphilisiwe elingu-1080 noma elingu-106 ngeke lisetshenziselwe zonke izingqimba zeshidi elilaphekiwe (ngaphandle kokuthi ikhasimende linezidingo ezikhethekile). Lapho ikhasimende lingenazo izidingo zobukhulu obuphakathi, ubukhulu obuphakathi phakathi kwezendlalelo kufanele kuqinisekiswe ukuthi bube ngu- ≥ 0.09mm ngokuya nge-ipc-a-600g.

(2) Lapho amakhasimende edinga ibhodi ephezulu ye-Tg, ibhodi lomgogodla kanye neshidi elipholile elizosebenzisa izinto ezihambisanayo eziphezulu ze-Tg.

(3) Nge-substrate yangaphakathi engu-3oz noma ngaphezulu, khetha ishidi elipholile elinokuqukethwe okuphezulu kwe-resin, njenge-1080r / C65%, 1080hr / C 68%, 106R / C 73%, 106hr / C76%; Kodwa-ke, ukwakheka kwawo wonke amashidi we-glue aphezulu angama-106 kufanele kugwenywe ngangokunokwenzeka ukuvimbela ukumelana kwamashidi amaningi aphilisiwe angama-106. Ngoba intambo yengilazi yefayibha incane kakhulu, intambo yengilazi yefayibha iyawa endaweni enkulu esezingeni eliphansi, ethinta ukuzinza kobukhulu kanye ne-delamination yokuqhuma kwepuleti.

(4) Uma ikhasimende lingenazo izidingo ezikhethekile, ukubekezelelana kobukhulu besendlalelo se-interlayer dielectric ngokuvamile kulawulwa ngu + / – 10%. Kwipuleti le-impedance, ukubekezelelana kobukhulu be-dielectric kulawulwa ukubekezelelana kwe-ipc-4101 C / M. Uma i-impedance ethonya isici ihlobene nobukhulu be-substrate, ukubekezelelana kwepuleti nakho kufanele kulawulwe ukubekezelelana kwe-ipc-4101 C / M.

Ukulawulwa kokuqondaniswa kwe-interlayer

Ngokunemba kwesinxephezelo sangaphakathi sebhodi lesisekelo nokulawulwa kukasayizi wokukhiqiza, kuyadingeka ukunxephezela ngokunembile usayizi ocacile woqweqwe ngalunye lwebhodi eliphakeme kakhulu ngokusebenzisa ulwazi nolwazi lwedatha oluqoqwe ekukhiqizeni isikhathi esithile ukuqinisekisa ukuvumelana ukunwetshwa nokuncipha koqweqwe ngalunye lwebhodi eyinhloko. Khetha imodi yokuma kwe-interlayer enemba kakhulu futhi enokwethenjelwa ngaphambi kokucindezela, njenge-pin Lam, inhlanganisela eshisayo ne-rivet. Ukusetha izinqubo zenqubo yokucindezela ezifanele kanye nokugcinwa kwansuku zonke komshini wokushicilela kuyisihluthulelo sokuqinisekisa ikhwalithi yokucindezela, ukulawula i-glue nokucindezela komphumela wokupholisa, nokunciphisa inkinga yokuhlukaniswa kwabadlali. Ukulawulwa kokuqondaniswa kokubandakanyeka kudinga ukucatshangelwa ngokuningiliziwe kusuka kuzinto ezifana nenani lesinxephezelo sangaphakathi, ukucindezela imodi yokuma, ukucindezela imingcele yenqubo, izici ezibonakalayo njalonjalo.

Inqubo yolayini engaphakathi

Ngoba ikhono lokuhlaziya lomshini wendabuko wokuvezwa lingaphansi kuka-50 μ M. ukukhiqizwa kwamapuleti aphezulu, i-laser imager ngqo (LDI) ingangeniswa ukwenza ngcono ikhono lokuhlaziya ihluzo, elingafinyelela ku-20 μ M noma kunjalo. Ukunemba kokuqondanisa komshini wokuchayeka wendabuko ngu- ± 25 μ m. Ukunemba kokuqondanisa kwesendlalelo kukhulu kunama-50 μ m. Kusetshenziswa umshini wokuchayeka wokucacisa okuphezulu, ukunemba kokuqondiswa kwehluzo kungathuthukiswa kube yi-15 μ M, ukulawulwa kokuqondiswa kokuqondiswa kokuphakathi kwe-30 μ M, okunciphisa ukuchezuka kokuqondanisa kwemishini yendabuko futhi kuthuthukise ukunemba kokuqondaniswa kwangaphakathi kwe-slab ephezulu.

Ukuze uthuthukise umthamo wokugcwala kolayini, kuyadingeka ukuthi unikeze isinxephezelo esifanele sobubanzi bomugqa nephedi (noma indandatho yokushisela) ekwakhiweni kobunjiniyela, kanye nokucatshangelwa okuningiliziwe kokuklanywa kwenani lesinxephezelo elikhethekile imidwebo, efana nolayini wokubuyela nolayini ozimele. Qinisekisa ukuthi isinxephezelo sokuklanywa sobubanzi bomugqa wangaphakathi, ibanga lomugqa, usayizi wering indandatho, umugqa ozimele nembobo ebangeni lolayini kunengqondo, uma kungenjalo shintsha ukwakhiwa kobunjiniyela. Kunezidingo zokuklanywa kwe-impedance kanye ne-inductive. Qaphela ukuthi isinxephezelo sokuklanywa kolayini ozimele nolayini we-impedance sanele. Lawula amapharamitha ngesikhathi sokudotshwa. Ukukhiqizwa kweqoqwana kungenziwa kuphela ngemuva kokuthi ucezu lokuqala luqinisekisiwe ukuthi lufanelekile. Ukuze unciphise ukugqwala kohlangothini lokudotshwa, kuyadingeka ukulawula ukwakheka kwamakhemikhali kweqembu ngalinye lesisombululo sokudonsa ngaphakathi kwebanga elihle kakhulu. Imishini yendabuko yokufaka umugqa inamandla okwanele okufaka. Le mishini ingaguqulwa ngobuchwepheshe noma ingeniswe kwimishini yomugqa wokunemba wokucacisa ukuze kuthuthukiswe ukufana kokugcoba futhi kunciphise izinkinga ezinjengonqenqemeni olubi nolokungcola okungcolile.

Inqubo yokucindezela ye-2.5

Njengamanje, izindlela zokuma phakathi kokucindezela ngaphambi kokucindezela ikakhulukazi zifaka: i-pin Lam, ukuncibilika okushisayo, i-rivet, kanye nenhlanganisela yokuncibilika okushisayo ne-rivet. Izindlela zokubeka ezihlukile zamukelwa izakhiwo ezahlukahlukene zomkhiqizo. Okwe-slab ephezulu, kuzosetshenziswa indlela yokubeka slot (i-pin Lam) noma indlela ye-fusion + riveting. Umshini wokushaya i-ope uzoshaya imbobo yokuma, futhi ukunemba kokushaya kuzolawulwa ngaphakathi kwe- ± 25 μ m. Ngesikhathi sokuhlanganiswa, i-X-ray izosetshenziselwa ukuhlola ukuphambuka kongqimba kwepuleti lokuqala elenziwe umshini wokulungisa, ne-batch kungenziwa kuphela ngemuva kokuphambuka kongqimba kufanelekile. Ngesikhathi sokukhiqizwa kwe-batch, kuyadingeka ukuhlola ukuthi ngabe ipuleti ngalinye liyancibilika yini kuyunithi ukuvimbela i-delamination elandelayo. Imishini yokucindezela isebenzisa ukusebenza kokusekela okuphezulu ukuhlangabezana nokunemba kokuqondaniswa kwesendlalelo nokuthembeka kwamapuleti aphezulu.

Ngokuya ngesakhiwo esinamaminerali sebhodi ephezulu kanye nezinto ezisetshenzisiwe, funda inqubo yokucindezela efanelekile, setha izinga lokushisa eliphakeme kakhulu kanye nejika, wehlise ngokufanelekile izinga lokukhuphuka kwezinga lokushisa lebhodi elicindezelwe enkambisweni yokucindezela yebhodi yesifunda ejwayelekile eminingi, ukwandisa isikhathi sokushisa okuphezulu okuphezulu, yenza i-resin igeleze ngokugcwele futhi iqinise, futhi ugweme izinkinga ezinjenge-sliding plate kanye ne-interlayer dislocation kwinqubo yokucindezela. Amapuleti anamanani ahlukile we-TG awakwazi ukufana namapuleti e-grate; Amapuleti anamapharamitha ajwayelekile awakwazi ukuxubaniswa namapuleti anamapharamitha akhethekile; Ukuqinisekisa ukuhleleka kokunwetshwa okunikeziwe kanye ne-coefficient enikeziwe, izakhiwo zamapuleti ahlukene namashidi aphulukisiwe amancane ahlukile, ngakho-ke ipuleti elihambisanayo lamapharamitha elashwa aphilayo adinga ukucindezelwa, futhi nemingcele yenqubo idinga ukuqinisekiswa ngezinto ezikhethekile akukaze kusetshenziswe.

2.6 inqubo yokubhola

Ngenxa yokushuba okungaphezulu kwepuleti nensimbi yethusi okubangelwe yisisekelo esingaphezulu sendlalelo ngayinye, i-drill bit igqoke kakhulu futhi kulula ukugqashula ibhithi yokuprinta. Inani lezimbobo, isivinini esiwayo nesivinini sokujikeleza lizoncishiswa ngokufanele. Linganisa ngokunembile ukwanda nokusikwa kwepuleti ukuze unikeze i-coefficient enembile; Uma inani lezendlalelo ≥ 14, ububanzi bomgodi ≤ 0.2mm noma ibanga ukusuka emgodini kuya kulayini ≤ 0.175mm, i-rig yokubhola ngokunemba kwesimo somgodi ≤ 0.025mm izosetshenziselwa ukukhiqiza; ubukhulu φ Ububanzi bomgodi ngenhla kuka-4.0mm bethola isinyathelo-nge-sinyathelo sokubhola, futhi ubukhulu besayizi wobukhulu ngu-12: 1. Ikhiqizwa ngesinyathelo ngesinyathelo sokubhola nokubhola okuhle nokungalungile; Lawula Burr futhi imbobo ukushuba imishini. Isilayidi esisezingeni eliphakeme sizobhalwa ngommese omusha wokumba noma ummese wokugaya ngangokunokwenzeka, futhi ubukhulu bomgodi buzolawulwa ngaphakathi kwama-25um. Ukuze uthuthukise inkinga yokubhola kwe-burr yamapuleti aphezulu wethusi ophakeme, ngokuqinisekiswa kwe-batch, ukusetshenziswa kwepuleti elisekela kakhulu, inani lamapuleti alaminishwe linye, futhi izikhathi zokugaya ze-drill bit zilawulwa ngaphakathi kwezikhathi ezi-3, ezingathuthukisa ngempumelelo i-burr yokubhola

Okwebhodi eliphakeme elisetshenziselwe imvamisa ephezulu, ukudluliswa kwedatha ngesivinini esikhulu nangokukhulu, ubuchwepheshe bokubhola emuva buyindlela ephumelelayo yokuthuthukisa ubuqotho besiginali. Ukubhoboza emuva ikakhulukazi kulawula ubude bezinsalela ezisele, ukuma kwesimo semigodi emibili kanye nocingo lwethusi emgodini. Akuyona yonke imishini yemishini yokubhola enomsebenzi wokumba emuva, ngakho-ke kuyadingeka ukuthi uthuthukise imishini yomshini wokubhola (ngomsebenzi wokumba emuva) noma uthenge umshini wokubhola onomsebenzi wokumba emuva. Ubuchwepheshe bokumba emuva obusetshenziswe emibhalweni ehlobene nomkhakha kanye nokukhiqizwa kwesisindo esivuthiwe ikakhulu kufaka phakathi: indlela yokulawula ukujula kwendabuko emuva, indlela yokubhola emuva ngesendlalelo sempendulo yesiginali kungqimba lwangaphakathi, nokubala ukujula emuva kokubhola ngokuya ngesilinganiso sobukhulu bepuleti. Ngeke kuphindwe lapha.

3, Ukuthembeka test

Ibhodi eliphakeme kakhulu ngokuvamile liyipuleti lesistimu, elijiyile futhi elinzima ukwedlula ipuleti elijwayelekile lezingqimba eziningi, linosayizi omkhulu weyunithi, namandla okushisa ahambelanayo nawo makhulu. Ngesikhathi sokushisela, kudingeka ukushisa okuningi futhi isikhathi sokushisa esine-welding side. Ku-217 ℃ (indawo encibilika nge-tin solder yethusi), kuthatha imizuzwana engama-50 kuye kumasekhondi angu-90. Ngasikhathi sinye, isivinini sokupholisa ipuleti ephakeme kakhulu sihamba kancane, ngakho-ke isikhathi sokuhlolwa kabusha siyandiswa. Kuhlanganiswe ne-ipc-6012c, amazinga we-IPC-TM-650 nezidingo zezimboni, ukuhlolwa okuyinhloko kokuthembeka kwebhodi eliphakeme kuyenziwa.