- 22

- Sep

Inkqubo engundoqo yolawulo lwemveliso yebhodi ye-PCB ePhakamileyo

Inkqubo yolawulo lwemveliso engundoqo yenqanaba eliphezulu PCB ibhodi

Ibhodi yesekethe ephezulu yokuphakama ichazwa ngokubanzi njengebhodi yesekethe ephezulu yokuphakama enemigangatho eyi-10-20 okanye nangaphezulu, ekunzima ngakumbi ukuyicwangcisa kunokwesiko ibhodi yesekethe emininzi kwaye inemfuno ezikumgangatho ophezulu kunye nokuthembeka. Isetyenziselwa izixhobo zonxibelelwano, iserver ephezulu, i-elektroniki yezonyango, ukuhamba ngenqwelomoya, ukulawulwa kwemizi-mveliso, ezomkhosi kunye nezinye iinkalo. Kwiminyaka yakutshanje, imfuno yentengiso yeebhodi eziphakamileyo eziphakamileyo kwicandelo lonxibelelwano lwesicelo, isikhululo sesiseko, ukuhamba ngenqwelomoya kunye nomkhosi womelele. Ngophuhliso olukhawulezileyo lwentengiso yezixhobo zonxibelelwano eTshayina, ithemba lentengiso leebhodi eziphakamileyo liyathembisa.

Ngoku, Umenzi PCBs ezinokuthi zivelise ubunzima be-PCB ephezulu e-China ikakhulu ivela kumashishini axhaswa ngemali angaphandle okanye kumashishini ambalwa asekhaya. Imveliso ye-PCB ephezulu ayifuni kuphela iteknoloji ephezulu kunye nezixhobo zotyalo-mali, kodwa kunye namava okuqokelelwa kwamagcisa kunye nabasebenzi bemveliso. Kwangelo xesha, iinkqubo zokuqinisekiswa kwabathengi zokungenisa i-PCB ephezulu ziyangqongqo kwaye zinzima. Ke ngoko, umqobo we-PCB ephezulu yokungena kwishishini iphezulu kwaye umjikelo wemveliso yoshishino mde. Inani eliphakathi lemiqolo ye-PCB iye yaba sisalathiso sobuchwephesha esibalulekileyo sokulinganisa inqanaba lobuchwephesha kunye nemveliso yeshishini le-PCB. Eli phepha lichaza ngokufutshane ubunzima bokuqhubekeka obuphambili ekuveliseni i-PCB ephezulu, kwaye yazisa amanqaku aphambili olawulo lweenkqubo eziphambili zemveliso ye-PCB ephezulu yokujonga.

1, ubunzima imveliso Main

Xa kuthelekiswa neempawu zeemveliso zebhodi yesekethe eqhelekileyo, ibhodi yesekethe ephezulu ineempawu zeebhodi ezishinyeneyo, umaleko ongaphezulu, imigca eshinyeneyo kunye ne-vias, ubungakanani beyunithi enkulu, umaleko we-dielectric ocekeceke, kunye neemfuno ezingqongqo zesithuba sangaphakathi, ulungelelwaniso lwabadlali, ulawulo lwe-impedance nokuthembeka.

1.1 ubunzima kulungelelwaniso lwabadlali

Ngenxa yenani elikhulu leebhodi eziphezulu zokunyuka, ukuphela koyilo lomthengi kuneemfuno ezingqongqo ngakumbi kulungelelwaniso lwee-PCB, kunye nokunyamezelana kokulungelelaniswa phakathi kwamanqanaba kuhlala kulawulwa kwi-± 75 μ m. Ukujonga uyilo olukhulu lobungakanani beyunithi yebhodi ephezulu yokuphakama, iqondo lobushushu lokuma kunye nokufuma kokuhanjiswa kwemizobo, ukuhanjiswa okungaphezulu kunye nemowudi yokuma yabadlali ebangelwe kukwandiswa okungahambelaniyo kunye nokuncipha kwemaleko yebhodi engundoqo eyahlukeneyo, kunzima ngakumbi ukulawula i-interlayer ukulungelelaniswa kwebhodi ephakamileyo.

1.2 ubunzima ekwenzeni isekethe yangaphakathi

Ibhodi yokuphakama ephezulu yamkela izinto ezizodwa ezinje nge-Tg ephezulu, isantya esiphezulu, amaza aphakamileyo, ubhedu obuninzi kunye nocingo lwe-dielectric ecekeceke, ebeka phambili iimfuno eziphezulu zokwenza ubungakanani kunye nolawulo lobungakanani bomzobo wesekethe yangaphakathi, njengokunyaniseka komqondiso we-impedance usulelo, olonyusa ubunzima bokuyila isekethe yangaphakathi. Ububanzi bomgca kunye nokushiyeka komgca zincinci, iisekethi ezivulekileyo nezimfutshane ziyanda, ukunyuka okufutshane okuncinci, kunye nenqanaba lemfundo lisezantsi; Kukho iindlela ezininzi zemigca ecikizekileyo, kunye nethuba lokulahleka kwe-AOI kulwakhiwo lwangaphakathi luyanda; Icwecwe elingaphakathi licekeceke, kulula ukusonga, nto leyo ekhokelela ekuvezeni okungafanelekanga, kwaye kulula ukuyiqengqa emva kokudumba; Uninzi lweebhodi eziphakamileyo eziphezulu ziibhodi zenkqubo enobungakanani beyunithi enkulu, kwaye indleko zokurhola iimveliso ezigqityiweyo ziphezulu kakhulu.

1.3 ukucinezela ubunzima bokuvelisa

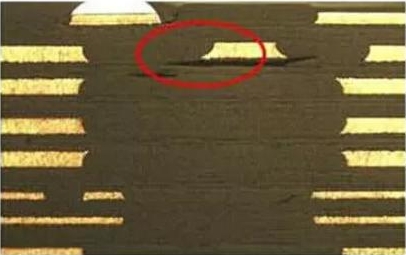

Xa iipleyiti ezingaphakathi ezininzi ezingaphakathi kunye namashiti anyangiweyo angaphezulu, iziphene ezinje ngokutyibilika kweplate, i-delamination, i-resin cavity kunye ne-bubble residue kulula ukwenzeka kwimveliso ye-crimping. Xa kuyilwa ubume elaminethiweyo, kufuneka uqwalasele ngokupheleleyo ukuxhathisa kobushushu, ukumelana ombane, iglu yokugcwalisa isixa kunye nobukhulu obuphakathi bezinto, kwaye usete inkqubo efanelekileyo yokunyusa ipleyiti ephezulu. Zininzi izaleko, kwaye ulawulo lokwanda kunye nokuncipha kunye nembuyekezo yobungakanani bokulingana ayinakulungelelana; Umaleko we-interlayer insulation ubhityile, kulula ukukhokelela ekusileleni kovavanyo lokuthembeka kwabadlali. Ikhiwane. 1 ngumzobo wesiphene sokuqhekeka kwepleyiti yokuqhekeka emva kovavanyo loxinzelelo lwethempile.

Umzobo.1

1.4 ubunzima bokugrumba

Ukusetyenziswa kwe-Tg ephezulu, isantya esiphezulu, ukuphakama okuphezulu kunye neepleyiti ezikhethekileyo zobhedu kwandisa ubunzima bokugrumba uburhabaxa, ukubhola burr kunye nokususa ukungcola. Kukho maleko ezininzi, ubukhulu ubhedu lilonke kunye ipleyiti ukutyeba ziqokelelwe, kwaye isixhobo zokomba kulula ukuba aphule; Ukusilela kweCaf okubangelwe yi-BGA eshinyeneyo kunye nokuqhekeka komda emngxunyeni odongeni; Ngenxa yobunzima beplate, kulula ukwenza ingxaki yokomba kwe-oblique.

2, inkqubo yolawulo imveliso Key

2.1 ukhetho lwezinto

Ngokuphuhliswa kwezinto ze-elektroniki kwicala lokusebenza okuphezulu kunye nemisebenzi emininzi, ikwazisa ukuhambisa amaza okuphezulu kunye nesantya esiphezulu. Ke ngoko, kufuneka ukuba ilahleko ye-dielectric rhoqo kunye nelahleko ye-dielectric yezixhobo zesekethe zombane ziphantsi kakhulu, kunye ne-CTE ephantsi, ukufunxwa kwamanzi okuphantsi kunye nokusebenza okungcono kokusebenza okuphezulu okunxityiwe izinto zokuhombisa, ukwenzela ukuhlangabezana neemfuno zokwenza kunye nokuthembeka okuphezulu iibhodi eziphakanyisiweyo. Abathengisi beepleyiti eziqhelekileyo ikakhulu kubandakanya uthotho, uthotho lwe-B, uC uthotho kunye no-D uthotho. Jonga iitheyibhile 1 ngokuthelekisa ezona mpawu ziphambili zezi zinto zingaphantsi zine. Kwibhodi yesekethe enobunzima obuphezulu obuphezulu, iphepha eliphilisiweyo elinomxholo okhethiweyo wentlaka likhethiwe. Isixa sokuqukuqela seglu kumaleko ophakathi wecandelo eliphilisiweyo lanele ukugcwalisa imizobo yangaphakathi. Ukuba ubushushu obuphakathi obugqithisileyo bukhulu kakhulu, ibhodi egqityiweyo kulula ukuba ibe nkulu kakhulu. Ngokuchasene noko, ukuba i-insulating medium layer icekeceke kakhulu, kulula ukuba ibangele iingxaki ezisemgangathweni ezinje nge-stratification ephakathi kunye nokusilela kovavanyo lwevolthi ephezulu. Ke ngoko, ukukhethwa kwezinto zokwambathisa eziphakathi kubaluleke kakhulu.

2.2 uyilo lolwakhiwo lweplastiki

Ezona zinto ziphambili ziqwalaselwe kuyilo lolwakhiwo olunemiphunga kukuchasa ubushushu, ukumelana kwamandla ombane, inani lokugcwalisa iglu kunye nobukhulu be-dielectric ubukhulu bezinto, kwaye kulandelwe le migaqo iphambili.

(1) Umvelisi wephepha eliphilisiweyo kunye nebhodi engundoqo kufuneka ihambelane. Ukuqinisekisa ukuthembeka kwe-PCB, iphepha elilodwa le-1080 okanye le-106 elinganyangekiyo alisayi kusetyenziswa kuzo zonke iileyili zephepha eliphilisiweyo (ngaphandle kokuba umthengi eneemfuno ezizodwa). Xa umthengi engenazo iimfuno zobukhulu obuphakathi, ubukhulu obuphakathi phakathi kwamanqanaba kufuneka kuqinisekiswe ukuba yi-0.09 600mm ngokwe-ipc-a-XNUMXg.

(2) Xa abathengi befuna ibhodi ephezulu ye-Tg, ibhodi engundoqo kunye nephepha eliphilisiweyo liza kusebenzisa izinto eziphezulu zeTG.

(3) Kwi-substrate yangaphakathi 3oz okanye ngaphezulu, khetha iphepha eliphilisiweyo elinomxholo ophezulu we-resin, njenge-1080r / C65%, 1080hr / C 68%, 106R / C 73%, 106hr / C76%; Nangona kunjalo, uyilo lolwakhiwo lwazo zonke iiglasi ezingama-106 eziphezulu zeglu ezinyangiweyo ziya kuthintelwa kangangoko kunokwenzeka ukuthintela ukubekwa ngaphezulu kwamaphepha ali-106 aphilileyo. Ngenxa yokuba umsonto wefayibha yeglasi ubhityile kakhulu, umsonto weglasi yefayibha uyawa kwindawo enkulu engaphantsi, echaphazela uzinzo lobungakanani kunye nokuqhushumba kwepleyiti.

(4) Ukuba umthengi akanazo iimfuno ezizodwa, ubukhulu bokunyamezelana komaleko we-dielectric elawulwa ngokubanzi ilawulwa + / – 10%. Kwisitya se-impedance, unyamezelo lobunzima be-dielectric lulawulwa yi-ipc-4101 C / M. Ukuba impedance echaphazela into inxulumene nobukhulu be-substrate, unyamezelo lweplate kufuneka lulawulwe kukunyamezelwa kwe-ipc-4101 C / M.

Ulawulo lokuhambelana kolungelelwaniso lwe-2.3

Ukuchaneka kwembuyekezo yangaphakathi yebhodi engundoqo yembuyekezo kunye nolawulo lobungakanani bemveliso, kufuneka ubuyekeze ngokuchanekileyo ubungakanani begraphic yomaleko ngamnye webhodi ephezulu yokunyuka ngedatha kunye namava edatha eyimbali eqokelelwe kwimveliso yexesha elithile ukuqinisekisa ukungqinelana ukwandiswa kunye nokuncipha kwoluhlu ngalunye lwebhodi engundoqo. Khetha ukuchaneka okuphezulu kunye nokuchaneka kwimowudi yokuma kwindawo yokudlala ngaphambi kokucinezela, njengepini yeLam, ukunyibilika okushushu kunye nokudibanisa rivet. Ukuseta iinkqubo ezifanelekileyo zokucinezela kunye nokugcinwa kwemihla ngemihla kumajelo oshicilelo ngumba ophambili wokuqinisekisa umgangatho wokucinezela, ukulawula iglu yokucinezela kunye nokupholisa ukusebenza, kunye nokunciphisa ingxaki yokusasazeka kwabadlali. Ukulawulwa kokulungelelaniswa kwabadlali abaninzi kufuneka kuthathelwe ingqalelo ngokubanzi kwizinto ezinje ngexabiso lembuyekezo yangaphakathi, imo yokucinezela, inkqubo yokucinezela iiparameter, izinto ezibonakalayo njalo njalo.

Inkqubo yangaphakathi ye-2.4

Kuba ukubanakho kohlalutyo lomatshini wokubonisa ngokwesiko kungaphantsi kwe-50 μ M. yokuveliswa kwamacwecwe aphakamileyo, i-laser ngqo yomfanekiso (LDI) inokwaziswa ukuphucula amandla ohlalutyo lwemizobo, enokufikelela kwi-20 μ M okanye njalo. Ukulungelelaniswa kokuchaneka komatshini wokubhenca ngokwesiko yi ± 25 μ m. Ukuchaneka kokulungelelaniswa komaleko omkhulu kungaphezulu kwe-50 μ m. Usebenzisa ulungelelwaniso oluphezulu lomatshini wokulungelelanisa, ukuchaneka kokulungelelaniswa kwemizobo kunokuphuculwa ukuya kwi-15 μ M, ulungelelwaniso lolungelelwaniso lwangaphakathi lokulinganisa 30 μ M, olwehlisa ulungelelwaniso lolungelelwaniso lwezixhobo zemveli kwaye luphucule ukuchaneka kokuhambelana kolungelelwaniso lwe-slab ephezulu.

Ukuphucula umthamo wokutsalwa komgca, kuya kufuneka unike imbuyekezo efanelekileyo kububanzi bomgca kunye nephedi (okanye iringi yokuwelda) kuyilo lobunjineli, kunye nokuqwalaselwa ngakumbi koyilo lwexabiso lembuyekezo. imizobo, enje ngomgca wokubuyela kunye nomgca ozimeleyo. Qinisekisa ukuba ngaba uyilo lwembuyekezo yobubanzi bomgca wangaphakathi, umgama womgca, ubungakanani bendandatho yokuzahlula, umgca ozimeleyo kunye nomngxunya kumgama womgama kufanelekile, kungenjalo utshintshe uyilo lobunjineli. Kukho ukunganyanzelekanga kunye neemfuno zokuyilwa kokuphendula kwakhona. Nika ingqalelo ekubeni uyilo lwembuyekezo yomgca ozimeleyo kunye nomgca we-impedance wanele. Lawula iiparameter ngexesha lokudinwa. Imveliso yeqela inokuqhutywa kuphela emva kokuba isiqwenga sokuqala siqinisekisiwe ukuba sikulungele. Ukunciphisa umhlwa wecala lokudamba, kufuneka ulawule ukwenziwa kweekhemikhali kwiqela ngalinye lesisombululo esinezinto ngaphakathi kolona luhlu lubalaseleyo. Isixhobo esine-line sokucheba sinesakhono sokufaka ngasekhohlo. Izixhobo zinokuthi ziguqulwe ngobuchwephesha okanye zingeniswe ngaphakathi kumatshini wokurola ngokuchaneka okuphezulu ukuphucula ukufana kokutsalwa kunye nokunciphisa iingxaki ezinje ngomphetho ombi kunye nokutsalwa okungacocekanga.

Inkqubo yokucinezela ye-2.5

Okwangoku, iindlela zokubeka phakathi kwabadlali ngaphambi kokucinezela ikakhulu zibandakanya: i-pin Lam, ukunyibilika okushushu, i-rivet, kunye nokudityaniswa kokunyibilika okushushu kunye ne-rivet. Iindlela ezahlukileyo zokubekwa zamkelwe kulwakhiwo lweemveliso ezahlukeneyo. Kwi-slab ephezulu yokunyuka, iindlela ezine zokubeka indawo (i-pin Lam) okanye indlela yokudibanisa + iya kusetyenziswa. Umatshini wokubetha i-ope uya kubetha umngxunya wokubekwa kwindawo, kwaye ukuchaneka kokuchwetheza kuya kulawulwa ngaphakathi kwe-25 μ m. Ngexesha lokudibana, i-X-ray iya kusetyenziselwa ukukhangela ukuphambuka komaleko kwipleyiti yokuqala eyenziwe ngumatshini wokulungisa, kunye nebhetshi inokwenziwa kuphela emva kokuba ukuphambuka komaleko kufanelekile. Ngexesha lokuveliswa kwebhetshi, kuyafuneka ukuba ujonge ukuba ingaba ipleyiti nganye inyibilikile na kwiyunithi ukunqanda ukungqinwa okulandelayo. Isixhobo sokucinezela samkela ukusebenza kweendaba okuxhasa ukuhlangabezana nokuchaneka kokulungelelaniswa kokuma kunye nokuthembeka kwamacwecwe aphakamileyo.

Ngokwendlela elaminethiweyo yebhodi ephezulu yokuphakama kunye nezinto ezisetyenzisiweyo, funda inkqubo yokucinezela efanelekileyo, usete elona xabiso liphezulu lokunyuka kweqondo lobushushu kunye negophe, ukunciphisa ngokufanelekileyo izinga lokunyuka kwebushushu kwibhodi ecinezelweyo kwinkqubo yokucinezela yebhodi yesekethe emininzi, Yandisa ixesha lokunyanga lobushushu obuphezulu, yenza i-resin iqukuqele ngokupheleleyo kwaye yomeleze, kwaye uphephe iingxaki ezinje ngokutyibilika kwipleyiti kunye nokusasazeka kwenkqubo yabadlali kwinkqubo yokucinezela. Amacwecwe anamaxabiso ahlukeneyo e-TG awanakufana neepleyiti zegrafiti; Iipleyiti ezineeparameter eziqhelekileyo azinakuxutywa kunye neepleyiti ezineeparameter ezizodwa; Ukuqinisekisa ulungelelwaniso lolwandiso olunikiweyo kunye nokulingana kokunciphisa, iipropathi zamacwecwe ahlukeneyo kunye namashiti anyangiweyo ahlukile, ke ipleyiti ehambelana nayo yeeparameter zeshiti eziphilileyo kufuneka zicofiwe, kwaye iiparameter zenkqubo kufuneka ziqinisekiswe ngezinto ezizodwa eziye zange yasetyenziswa.

Inkqubo yokomba 2.6

Ngenxa ukutyeba phezu ipleyiti nobhedu umaleko okubangelwa superposition maleko ngalunye, isuntswana drill kunxitywa kakhulu kwaye kulula ukuba aphule bit drill. Inani lemingxunya, isantya esiwayo kunye nesantya esijikelezayo liya kuncitshiswa ngokufanelekileyo. Ukulinganisa ngokuchanekileyo ukwanda kunye nokuncipha kwesitya ukubonelela ngokulingana okuchanekileyo; Ukuba inani lamanqanaba ≥ 14, ubukhulu bomngxunya ≤ 0.2mm okanye umgama ukusuka emngxunyeni ukuya emgceni ≤ 0.175mm, isixhobo sokugrumba esinendawo yokuchaneka ngokuchanekileyo ≤ 0.025mm iya kusetyenziswa kwimveliso; ubukhulu hole Ububanzi umngxuma ngasentla 4.0mm isebenzisa step-by-step ukubhola, kwaye ubukhulu ubukhulu ubukhulu yi 12: 1. Iveliswa ngokwenyathelo ngamanyathelo lokomba kunye nokumba okuqinisekileyo nokungalunganga; Lawula burr kunye umngxuma ukutyeba ukubhola. Isilayidi esonyuka phezulu siyakugrunjwa ngemela entsha yokugrumba okanye imela yokugaya kude kangangoko kunokwenzeka, kwaye ubukhulu bomngxunya buya kulawulwa ngaphakathi kwe25um. Ukuze kuphuculwe ingxaki yokomba burr of ipleyiti ashinyeneyo eliphezulu-ukunyuka, ngokusebenzisa ungqinisiso ibhetshi, ukusetyenziswa koxinano ipleyiti ezixineneyo, inani lamacwecwe elaminethiweyo yenye, kwaye amaxesha besila intwana yokomba ilawulwa ngaphakathi amaxesha 3, ezinokuphucula ngokufanelekileyo ukubhola

Kwibhodi ephezulu esetyenzisiweyo Isantya esiphezulu, isantya esiphezulu kunye nokuhanjiswa kwedatha okukhulu, itekhnoloji yokubuyisa umva yindlela efanelekileyo yokuphucula ukuthembeka. Ukugrumba ngasemva ubukhulu becala kulawula intsalela yobude besikhondo, indawo emngxunyeni engqinelanayo yamaqula amabini kunye nocingo lobhedu emngxunyeni. Ayizizo zonke izixhobo zomatshini wokugrumba onemisebenzi yokubuyela umva, ke kuyafuneka ukuphucula izixhobo zokomba (ngomsebenzi wokubuyela umva) okanye ukuthenga umatshini wokugrumba ngomsebenzi wokugrumba ngasemva. Itekhnoloji yokubhola ngasemva esetyenziswe kuncwadi olunxulumene nomzi mveliso kunye nokuveliswa kwemveliso ngobuninzi ikakhulu kubandakanya: indlela yokulawula ubunzulu yokubuyela umva kwindlela yokubamba, ukubuyela umva ngophawu lwempendulo yomaleko ngaphakathi, kunye nokubala ubunzulu bokubuyela umva ngokungqinelana nenani leplate. Ayizuphinda iphindwe apha.

3, uvavanyo ukuthembeka

Ibhodi yokuphakama okuphezulu ngokubanzi yipleyiti yenkqubo, etyebileyo kwaye inzima kunepleyiti yesiqhelo esinee-multilayer ezininzi, inobungakanani beyunithi enkulu, kunye nobushushu obuhambelanayo nobukhulu bukhulu. Ngexesha lokuwelda, kufuneka ubushushu obungaphezulu kwaye ixesha elitshisayo lokuwelda lide. Ku 217 ℃ (indawo yokunyibilika yetin yesilivere ityhidiweyo), kuthatha imizuzwana engama-50 ukuya kwimizuzwana engama-90. Kwangelo xesha, isantya sokupholisa ipleyiti ephezulu inyuka kancinci, ke ixesha lokuvavanywa kwakhona lihlala ixesha elide. Idityaniswe ne-ipc-6012c, imigangatho ye-IPC-TM-650 kunye neemfuno zeshishini, olona vavanyo luthembekileyo lwebhodi ephezulu yenziwa.