- 06

- Oct

Yadda ake warware matsalar tagulla da aka lullube da PCB

Yadda za a magance matsalar laminate na tagulla PCB

Anan akwai wasu matsalolin hukumar PCB na yau da kullun da yadda ake tabbatar dasu. Da zarar an ci karo da matsalar laminate na PCB, yakamata a yi la’akari da ƙara shi zuwa ƙayyadaddun Layin PCB. Yadda za a warware matsalar tagulla da aka lulluɓe da PCB?

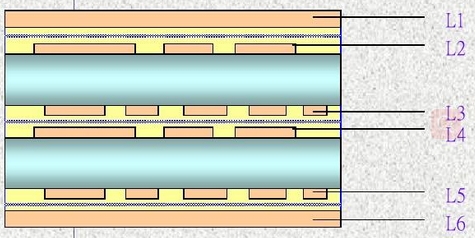

Kwamitin kewaye na PCB na jan ƙarfe laminate matsala i. Don samun damar bincika

Ba shi yiwuwa a ƙera kowane adadin PCB ba tare da fuskantar wasu matsaloli ba, wanda galibi saboda kayan PCB laminate ne. Lokacin da matsaloli masu inganci ke faruwa a cikin ainihin tsarin masana’antu, da alama kayan PCB substrate galibi shine ke haifar da matsalar. Ko da takamaiman rubuce da aiwatar da takamaiman fasaha don laminate PCB ba ya ƙayyade abubuwan gwajin da dole ne a aiwatar don tantance cewa laminates PCB sune sanadin matsalolin aiwatar da samarwa. Anan akwai wasu matsalolin PCB Laminate na yau da kullun da yadda ake tabbatar dasu.

Da zarar an ci karo da matsalar laminate na PCB, yakamata a yi la’akari da ƙara shi zuwa ƙayyadaddun Layin PCB. Yawancin lokaci, idan ba a wadatar da wannan ƙayyadaddun fasaha ba, zai haifar da canje -canje masu inganci na ci gaba da haifar da ɓarkewar samfur. Gabaɗaya, matsalar kayan da aka haifar ta canjin ƙimar PCB Laminate yana faruwa a cikin samfuran da aka ƙera tare da ɗimbin albarkatun ƙasa ko nauyin latsa daban -daban. Masu amfani kaɗan ne ke da isassun bayanan don rarrabe takamaiman nauyin latsawa ko rukunin kayan aiki a wurin sarrafawa. Don haka sau da yawa yakan faru cewa ana samar da PCB akai -akai kuma ana shigar da shi tare da abubuwan haɗin gwiwa, kuma ana ci gaba da samar da warpage a cikin tsagi mai siyarwa, wanda ke ɓatar da aiki da abubuwa masu tsada. Idan ana iya samun lambar rukunin caji nan da nan, mai ƙera PCB Laminate zai iya duba adadin rukunin resin, foil na jan ƙarfe, sake zagayowar warkarwa, da dai sauransu A wasu kalmomin, idan mai amfani ba zai iya samar da ci gaba da tsarin kula da ingancin PCB Laminate manufacturer ba. , mai amfani da kansa zai sha wahala na dogon lokaci. Mai zuwa yana bayyana manyan matsalolin da suka danganci kayan substrate a cikin tsarin sarrafa PCB.

Matsalar kewaye PCB tagulla sanye da laminate matsala 2. Matsalar farfajiya

Alamomin cutar: mannewa mara kyau na kayan bugawa, manne mara kyau na sutura, wasu sassa ba za a iya saƙa su ba, wasu sassan kuma ba za a iya siyar da su ba.

Hanyoyin dubawa mai yuwuwa: ana yin binciken gani ta hanyar samar da alamun ruwa a bayyane a saman farantin:

Dalili mai yiwuwa:

Saboda kauri mai kauri da santsi da fim ɗin da ke ruɓewa, saman jan ƙarfe wanda ba a rufe shi ba ya yi haske sosai.

Yawancin lokaci, mai ƙera laminate baya cire wakilin sakin a gefen da ba a rufe shi ba.

Pinholes a cikin foil na jan ƙarfe yana haifar da resin ya fita ya tara a saman murfin jan ƙarfe, wanda galibi yana faruwa akan ƙirar jan ƙarfe fiye da ƙayyadaddun nauyi na 3 /4 oz.

Masu kera bango na jan ƙarfe suna amfani da antioxidants da yawa akan farfajiyar jan ƙarfe.

Masu ƙera laminate sun canza tsarin resin, takardar saki, ko hanyoyin gogewa.

Saboda aiki mara kyau, akwai yatsun hannu da yawa ko tabo na mai.

An gurɓata mai a lokacin hudawa, huda ko aikin hakowa.

Matsaloli da ka iya yiwuwa:

Haɗa kai tare da masana’anta laminate kuma saka abubuwan gwajin mai amfani kafin a yi kowane canje -canje ga masana’antar laminate.

Ana ba da shawarar cewa masana’antun laminate su yi amfani da masana’anta kamar fina -finai ko wasu kayan fitarwa.

Tuntuɓi mai ƙera laminate don bincika kowane rukunin farantin jan ƙarfe wanda ya kasa wuce binciken; Tambayi mafita don cire resin da aka ba da shawarar.

Tambayi mai ƙera laminate don hanyar cirewa. Gabaɗaya ana ba da shawarar yin amfani da acid hydrochloric, sannan a cire shi ta hanyar niƙa ta injiniya da gogewa.

Tuntuɓi mai ƙera laminate don amfani da hanyoyin kawar da inji ko sinadarai.

Ilmantar da duk ma’aikatan da ke aiki don sanya safofin hannu da ɗaukar laminates na jan ƙarfe. Tabbatar ko an saka laminate da kyau ko kunshe a cikin jakar yayin sufuri, kuma abun da ke cikin sulfur na takarda da aka saka ya yi ƙasa, kuma jakar kayan ba ta da datti. Kula da hankali don tabbatar da cewa babu wanda ke tuntuɓar takardar jan ƙarfe lokacin amfani da kayan wankewa da ke ɗauke da silicone.

Degrease duk laminates kafin plating ko hoto canja wurin tsari