- 06

- Oct

Indlela yokusombulula ingxaki yobhedu egqoke i-laminate ye-PCB

Indlela yokusombulula ingxaki yobhedu egqoke i-laminate ye PCB

Nazi ezinye zeengxaki zebhodi yePCB kunye nendlela yokuziqinisekisa. Nje ukuba ingxaki ye-laminate ye-PCB ifumaneke, kufanele kuthathelwe ingqalelo ukuyongeza kwinkcazo ye-PCB Laminate. Indlela yokusombulula ingxaki yobhedu egqoke laminate of PCB?

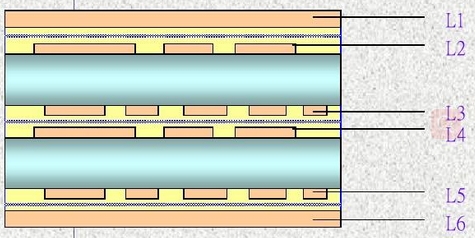

Ibhodi yesekethe yebhodi yengubo yobhedu enxibe ilaminate i. Ukuze ukwazi ukukhangela

Akunakwenzeka ukuvelisa naliphi na inani le-PCB ngaphandle kokuhlangabezana neengxaki ezithile, ikakhulu ngenxa yemathiriyeli ye-PCB enxitywe i-laminate. Xa iingxaki ezisemgangathweni zisenzeka kwinkqubo yokwenziwa kwemveliso, kubonakala ngathi izinto ze-PCB ze-substrate zihlala zingunobangela wengxaki. Nokuba ebhalwe ngocoselelo kwaye yaphunyezwa imigaqo yobuchwephesha ye-PCB laminates ayichazi izinto zovavanyo ekufuneka zenziwe ukumisela ukuba ii-laminates ze-PCB zingunobangela weengxaki zemveliso. Nazi ezinye zeengxaki eziqhelekileyo ze-PCB Laminate kunye nendlela yokuziqinisekisa.

Nje ukuba ingxaki ye-laminate ye-PCB ifumaneke, kufanele kuthathelwe ingqalelo ukuyongeza kwinkcazo ye-PCB Laminate. Ngokwesiqhelo, ukuba le nto yobuchwephesha ayityebiswanga, iya kubangela utshintsho lomgangatho oluqhubekayo kwaye ikhokelele ekukhutsheni imveliso. Ngokubanzi, ingxaki yemathiriyeli ebangelwe lutshintsho lwePBP Laminate esemgangathweni ivela kwiimveliso ezenziwe ngeebhetshi ezahlukeneyo zempahla ekrwada okanye imithwalo eyahlukeneyo yokucinezela. Bambalwa abasebenzisi abanerekhodi ezaneleyo zokwahlula umthwalo othile wokucinezela okanye ibhetshi yempahla kwindawo yokulungisa. Ke ihlala isenzeka ukuba i-PCB iveliswa rhoqo kwaye ifakwe ngezinto, kwaye i-warpage iqhubeka ngokuqhubekayo kwindawo ye-solder, echitha uninzi lwabasebenzi kunye nezinto ezibizayo. Ukuba inani lokulayishwa kwebhetshi lingafumaneka kwangoko, umenzi we-PCB Laminate angajonga inani lebhetshi yentlaka, ifoyile yobhedu, umjikelo wokuphilisa, njl Ngamanye amagama, ukuba umsebenzisi akanakho ukubonelela ngokuqhubekeka nenkqubo yolawulo lomgangatho womenzi wePCB Laminate , Umsebenzisi uqobo uya kuva ilahleko ixesha elide. Oku kulandelayo kuchaza iingxaki ngokubanzi ezinxulumene nezinto ze-substrate kwinkqubo yokuvelisa ye-PCB.

Ibhodi yesekethe yebhodi yengubo yobhedu enxibe ilaminate ingxaki 2. Ingxaki yomphezulu

Iimpawu: Ukubambelela okungalunganga kwezinto zokuprinta, ukubambelela okungalunganga kwento yokuhombisa, ezinye iindawo azinakumiswa, kwaye ezinye iindawo azinakuthengiswa.

Iindlela ezinokubakho zokuhlola: ukubonwa okubonakalayo kuhlala kwenziwa ngokwenza amanqaku amanzi abonakalayo kumgangatho wepleyiti:

Izizathu ezinokwenzeka:

Ngenxa yendawo eshinyeneyo kunye egudileyo ebangelwe yifilimu eyonakalisayo, umphezulu wobhedu ongagqunywanga ukhazimla kakhulu.

Ngokwesiqhelo, umenzi we-laminate akasusi iarhente yokukhutshwa kwicala elingafakwanga laminate.

Iiphini ezenziwe ngefoyile yobhedu zibangela ukuba i-resin iphume kwaye iqokelele kumphezulu wefoyile yobhedu, edla ngokwenzeka kwifoyile yobhedu engaphantsi kwe-3/4 oz.

Abenzi beefoyile zobhedu basebenzise ii-antioxidants ezigqithileyo kumphezulu wefoyile yobhedu.

Abavelisi beLaminate batshintshe iinkqubo ze-resin, ukukhupha amashiti, okanye iindlela zokuxubha.

Ngenxa yokusebenza okungalunganga, mininzi iminwe okanye amabala eoyile.

I-oyile inamabala ngexesha lokubetha, ukungabinanto okanye ukubhola.

Izisombululo ezinokubakho:

Sebenzisana nomenzi we-laminate kwaye ucacise izinto zovavanyo zomsebenzisi ngaphambi kokuba kwenziwe naluphi na utshintsho kwimveliso yokuqaqamba.

Kuyacetyiswa ukuba abavelisi be-laminate basebenzise amalaphu afana neefilimu okanye ezinye izinto zokukhululwa.

Nxibelelana nomenzi we-laminate ukuze uhlole ibhetshi nganye yefoyile yobhedu engaphumeleliyo ukupasa uhlolo; Cela isisombululo sokususa i-resin ekhuthazwayo.

Buza umenzi we-laminate malunga nendlela yokususa. Kucetyiswa ngokubanzi ukuba kusetyenziswe i-hydrochloric acid, emva koko uyisuse ngokuguba ngomatshini kunye nokuxubha.

Nxibelelana nomenzi we-laminate ukuze usebenzise iindlela zokuphelisa umatshini.

Fundisa bonke abasebenzi benkqubo ukuba banxibe iigloves kwaye bathabathe ii-laminates ezinxibe ubhedu. Qinisekisa ukuba i-laminate ifakwe kakuhle okanye ipakishwe engxoweni ngexesha lokuhamba, kwaye umxholo wesalfure kwiphepha eligciniweyo liphantsi, kwaye ingxowa yokupakisha ayinakho ukungcola. Nika ingqalelo ukuze uqiniseke ukuba akukho mntu unxibelelana nefoyile yobhedu xa usebenzisa isepha ene-silicone.

Zisuse zonke ii-laminates ngaphambi kokutyabeka okanye inkqubo yokuhambisa umzobo