- 06

- Oct

Ungayixazulula kanjani inkinga yethusi egqoke i-laminate ye-PCB

Ungayixazulula kanjani inkinga yethusi egqoke i-laminate ye PCB

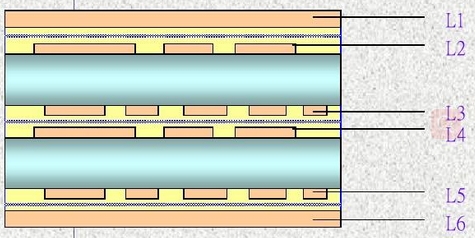

Nazi ezinye zezinkinga zebhodi le-PCB ezivame kakhulu nokuthi ungaziqinisekisa kanjani. Lapho inkinga ye-laminate ye-PCB ihlangabezane nayo, kufanele kucatshangwe ukuyifaka esicacisweni se-PCB Laminate. Indlela ukuxazulula inkinga zethusi egqoke laminate of PCB?

PCB wesifunda ibhodi zethusi egqoke laminate inkinga i. Ukuze ukwazi ukusesha

Akunakwenzeka ukuthi kukhiqizwe noma yiliphi inani le-PCB ngaphandle kokuhlangabezana nezinkinga ezithile, ikakhulukazi ngenxa yento eyenziwe nge-laminate egqoke ithusi ye-PCB. Lapho izinkinga zekhwalithi zenzeka enqubeni yokukhiqiza yangempela, kubonakala sengathi into esezingeni eliphansi ye-PCB imvamisa iyimbangela yenkinga. Ngisho nokubhalwa kwezobuchwepheshe okulotshwe ngokucophelela nokusetshenzisiwe kwama-laminate e-PCB akuchazi izinto zokuhlola okufanele zenziwe ukuthola ukuthi ama-laminate e-PCB ayimbangela yezinkinga zenqubo yokukhiqiza. Nazi ezinye zezinkinga ezivame kakhulu ze-PCB Laminate nokuthi ungaziqinisekisa kanjani.

Lapho inkinga ye-laminate ye-PCB ihlangabezane nayo, kufanele kucatshangwe ukuyifaka esicacisweni se-PCB Laminate. Imvamisa, uma le ncazelo yezobuchwepheshe inganothiswanga, izodala ushintsho lwekhwalithi eqhubekayo futhi iholele ekususweni komkhiqizo. Ngokuvamile, inkinga ebonakalayo ebangelwa ukuguqulwa kwekhwalithi ye-PCB Laminate ivela emikhiqizweni eyenziwe ngamaqoqo ahlukahlukene wezinto zokusetshenziswa noma imithwalo ehlukahlukene yokucindezela. Bambalwa abasebenzisi abanamarekhodi anele ukuhlukanisa umthwalo othile wokucindezela noma iqoqo lezinto ezibonakalayo kusayithi lokucubungula. Ngakho-ke kwenzeka kaningi ukuthi i-PCB ikhiqizwa njalo futhi ifakwe nezakhi, futhi i-warpage ikhiqizwa ngokuqhubekayo emgodini we-solder, ochitha izinto eziningi zabasebenzi nezindleko. Uma inombolo ye-batch yokulayisha itholakala ngokushesha, umenzi we-PCB Laminate angabheka inombolo ye-batch ye-resin, ucwecwe lwethusi, umjikelezo wokulapha, njll. , umsebenzisi uqobo uzolahlekelwa isikhathi eside. Okulandelayo kuchaza izinkinga ezijwayelekile ezihlobene nezinto ezisetshenziswayo kunqubo yokukhiqiza ye-PCB.

PCB wesifunda ibhodi zethusi egqoke laminate inkinga 2. Inkinga Surface

Izimpawu: ukunamathela okungalungile kwezinto zokuphrinta, ukunamathela okungahambi kahle kwezingubo, ezinye izingxenye azikwazi ukuqoshwa, kanti ezinye izingxenye azikwazi ukuthengiswa.

Izindlela zokuhlola ezingenzeka: ukuhlolwa okubukwayo kuvame ukwenziwa ngokwakha amamaki amanzi ebusweni bepuleti:

Izimbangela ezingenzeka:

Ngenxa yendawo eminyene futhi ebushelelezi ebangelwe yifilimu eyonakalisayo, indawo yethusi engamboziwe ikhanya kakhulu.

Imvamisa, umenzi we-laminate akayisusi i-ejenti yokukhipha ohlangothini olungafakwanga laminate.

Ama-pinholes ocwecweni lwethusi abangela ukuthi i-resin iphume futhi iqoqane ebusweni bethusi lethusi, okuvamise ukwenzeka kucwecwe lwethusi oluncane kunokucaciswa kwesisindo esingu-3/4 oz.

Abenzi bamapulangwe wethusi basebenzisa ama-antioxidants amaningi ngokweqile ebusweni bensimbi yethusi.

Abakhiqizi be-laminate bashintshe izinhlelo ze-resin, bakhipha amashidi, noma izindlela zokuxubha.

Ngenxa yokusebenza okungalungile, kunezigxivizo zeminwe eziningi noma amabala kawoyela.

Uwoyela unamabala ngesikhathi sokubhoboza isibhakela, ukuvala isikhala noma ukubhola.

Izixazululo ezingaba khona:

Bambisana nomkhiqizi we-laminate futhi ucacise izinto zokuhlola zomsebenzisi ngaphambi kokuba kwenziwe ushintsho ekukhiqizeni i-laminate.

Kunconywa ukuthi abakhiqizi be-laminate basebenzise indwangu efana namafilimu noma ezinye izinto zokukhishwa.

Xhumana nomkhiqizi we-laminate ukuze uhlole iqoqo ngalinye le-foil yethusi elihluleka ukudlulisa ukuhlolwa; Cela isixazululo sokususa i-resin enconyiwe.

Buza umenzi we-laminate ngendlela yokususa. Ngokuvamile kunconywa ukusebenzisa i-hydrochloric acid, bese uyisusa ngokugaya ngomshini nangokuxubha.

Xhumana nomkhiqizi we-laminate ukuze usebenzise izindlela zokuqeda imishini noma zamakhemikhali.

Fundisa bonke abasebenzi bezinqubo ukugqoka amagilavu futhi bathathe ama-laminates egqoke ithusi. Qiniseka ukuthi i-laminate igcwele kahle noma igcwele esikhwameni ngesikhathi sokuhamba, futhi okuqukethwe kwesibabule ephepheni eligxiliwe kuphansi, futhi isikhwama sokupakisha asinakho ukungcola. Naka ukuqinisekisa ukuthi akekho othinta ucwecwe lwethusi lapho usebenzisa i-detergent equkethe abicah.

Hlukanisa wonke ama-laminate ngaphambi kokufakwa noma inqubo yokudlulisa imidwebo