- 27

- Apr

Kodi tiyenera kulabadira chiyani PCBA processing? Mfundo zofunika chisamaliro PCBA processing

SMT proofing ndi katswiri PCBA processing wopanga ndi PCB Factory ndi SMT chigamba processing fakitale, amene angapereke. PCBA imodzi ntchito processing monga PCB proofing, chigawo kugula, SMT chigamba, kuviika pulagi-mu, PCBA kuyezetsa, anamaliza mankhwala msonkhano ndi zina zotero. Nazi zinthu zomwe zikufunika chisamaliro pakukonza kwa PCBA.

Mavuto ayenera kuganiziridwa popanga PCBA

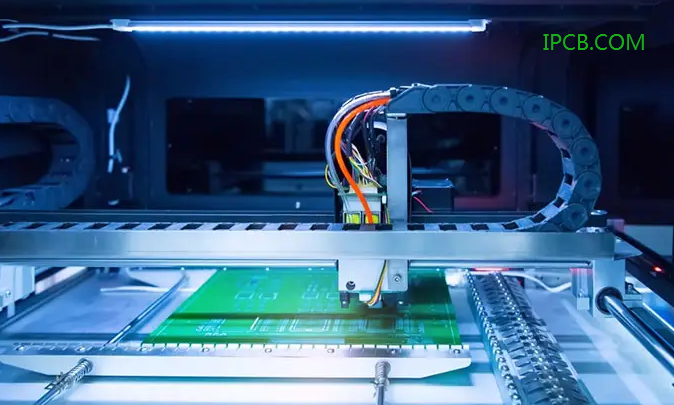

1. Mapangidwe a bolodi limodzi ndikuyika zinthu mumzere wopanga zokha

Pakuti zodziwikiratu kupanga mzere msonkhano, PCBA ayenera kukhala ndi luso kufalitsa m’mphepete ndi kuwala malo zizindikiro, chimene ndi chofunika kuti producibility.

2. PCBA msonkhano ndondomeko kamangidwe

Kapangidwe ka masanjidwe a zigawo kutsogolo ndi kumbuyo kwa PCBA chimatsimikizira ndondomeko njira ndi njira pa msonkhano.

3. Kapangidwe kagawo kagawo

Kupanga malo, mayendedwe ndi masinthidwe a zigawo pamalo osonkhana. Kamangidwe ka zigawo zikuluzikulu zimadalira njira kuwotcherera anatengera. Njira iliyonse yowotcherera imakhala ndi zofunikira zenizeni za malo, mayendedwe ndi katayanidwe ka magawo.

4. Msonkhano ndondomeko kapangidwe

Pakupanga kuwotcherera kumadutsa mulingo, kudzera pamapangidwe ofananira a pedi, kuwotcherera kukana ndi mauna achitsulo, kugawa kokhazikika komanso kokhazikika kwa phala la solder kumakwaniritsidwa; Kupyolera mu kamangidwe ka masanjidwe ndi mawaya, synchronous kusungunuka ndi kulimbitsa mafupa onse solder phukusi limodzi akhoza anazindikira; Kupyolera mu kulumikiza koyenera kwa dzenje loyikapo, 75% kulowetsedwa kwa malata kumatha kutheka. Zolinga zamapangidwe awa pomaliza pake ndikuwongolera zokolola zowotcherera.

Kusamala kwa PCBA kuwotcherera

1. Woyang’anira nyumba yosungiramo katundu ayenera kuvala magolovesi otsutsa-static pamene akupereka zipangizo ndi kuyesa IQC, ndipo chidacho chiyenera kukhala chokhazikika, ndipo chogwiritsira ntchito chidzapangidwa ndi anti-static rubber pad pasadakhale.

2. Pogwira ntchito, ma anti-static worktops amagwiritsidwa ntchito, ndipo zitsulo zotsutsana ndi zowonongeka zimagwiritsidwa ntchito kugwiritsira ntchito zigawo ndi zinthu zomwe zatha. Zida zowotcherera za dipatimentiyo zitha kukhazikitsidwa, ndipo chitsulo chamagetsi chamagetsi chiyenera kukhala chamtundu wa anti-static. Zida zonse ziyenera kuyesedwa musanagwiritse ntchito.

3. Pamene PCBA ndi kukonzedwa mwa ng’anjo, chifukwa zikhomo za pulagi-mu zinthu otsukidwa ndi malata otaya, ena pulagi-mu zinthu adzakhala mapendekedwe pambuyo kuwotcherera, chifukwa mu element thupi kuposa silika chophimba chimango. Choncho, kukonza kuwotcherera ogwira ntchito pambuyo malata ng’anjo chofunika kukonza bwino.

4. Pamene PCBA ndi kuwotcherera nyanga ndi batire, tiyenera kudziŵika kuti solder olowa sadzakhala kwambiri, amene sadzakhala chifukwa dera lalifupi kapena kugwa kwa zigawo zozungulira.

5. Magawo a PCBA adzayikidwa mwaukhondo, ndipo mbale zopanda kanthu sizingapakidwe mwachindunji. Ngati stacking ikufunika, iyenera kudzazidwa m’matumba a electrostatic.

Kusamala kwa PCBA anamaliza msonkhano mankhwala

1. Makina onse opanda chipolopolo amagwiritsa ntchito anti-static thumba thumba

Yang’anani nthawi zonse zida zotsutsana ndi static, zoikamo ndi zipangizo kuti muwonetsetse kuti ntchitoyo ikukwaniritsa zofunikira.

2. Mukasonkhanitsa zomalizidwa, tsatirani njira zotsatirazi

Malo osungiramo katundu → mzere wopanga → pulogalamu yokweza mzere wopanga → kusonkhanitsa mu makina athunthu → kuyesa kwa QC → lembani nambala ya IMEI → QA kuyang’ana kwathunthu → bwezeretsani zoikamo za fakitale → malo osungira; Pulogalamuyi idzakwezedwa musanayambe msonkhano. Sizingasonkhanitsidwe mu makina omalizidwa ndi kukwezedwa. Iwo mwina akweza chifukwa zosayenera kuwotcherera, dera lalifupi, mavuto ndondomeko ntchito, etc., chifukwa molakwika PCBA zoipa.

Zomwe zili pamwambazi ndi zomwe zimafunikira chisamaliro pakukonza kwa PCBA? PCBA processing ayenera kulabadira kumayambiriro mfundo, ine ndikuyembekeza kungakuthandizeni.