- 27

- Apr

Chii chatinofanira kutarisisa muPCBA kugadzirisa? Mapoinzi anoda kutariswa muPCBA kugadzirisa

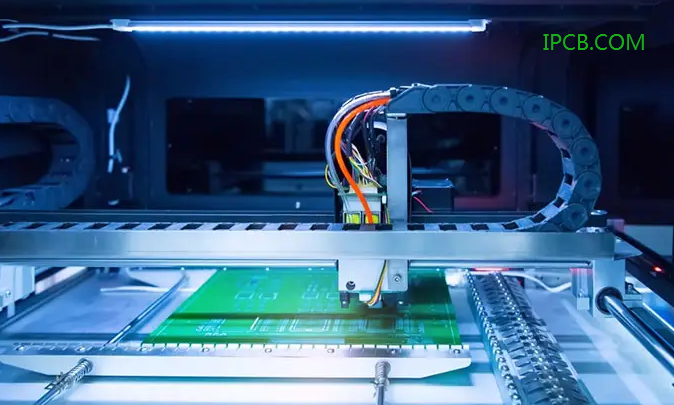

SMT proofing inyanzvi PCBA yekugadzirisa inogadzira ine yayo PCB Factory uye SMT chigamba kugadzirisa fekitori, inogona kupa. imwe-chimisa PCBA kugadzirisa masevhisi akadai sePCB proofing, chikamu chekutenga, SMT chigamba, dip plug-in, PCBA yekuyedza, yakapera chigadzirwa kusangana uye zvichingodaro. Hezvino zvinhu zvinoda kutariswa muPCBA kugadzirisa.

Matambudziko anofanirwa kutariswa mukugadzira PCBA

1. Dhizaini yeimwe bhodhi kutapurirana uye chinzvimbo zvinhu mune otomatiki yekugadzira mutsara

Kune otomatiki yekugadzira mutsara musangano, PCBA inofanirwa kuve nekugona kufambisa kumucheto uye yemaziso ekumisikidza zviratidzo, zvinova zvinodikanwa pakugadzirwa.

2. PCBA musangano wekugadzira maitiro

Iyo dhizaini dhizaini yezvikamu kumberi uye kumashure kwePCBA inosarudza nzira yemaitiro uye nzira panguva yekusangana.

3. Chikamu chekugadzirisa dhizaini

Dhizaina chinzvimbo, kutungamira uye kupatsanurana kwezvikamu panzvimbo yegungano. Kurongeka kwezvikamu kunoenderana newelding nzira yakagamuchirwa. Imwe neimwe nzira yewelding ine chaiyo inodiwa kune marongerwo chinzvimbo, kutungamira uye kupatsanura kwezvikamu.

4. gungano process design

Kuti dhizaini yewelding ipfuure nechiyero, kuburikidza nekufananidza dhizaini yepadhi, kuramba welding uye simbi mesh, iyo yehuwandu uye yakagadziriswa-yakagadzika-inogadzika kugovera kwe solder paste inoitika; Kuburikidza nedhizaini yekumisikidza uye wiring, iyo synchronous kunyunguduka uye kusimba kwemajoini ese ekutengesa mupakeji imwe chete inogona kuitika; Kuburikidza neiyo inonzwisisika yekubatanidza dhizaini yegomba rekukwira, 75% tin yekupinda mwero inogona kuwanikwa. Zvinangwa zvekugadzira izvi pakupedzisira kuvandudza goho rewelding.

Chengetedzo yePCBA welding

1. Muchengeti weimba yekuchengetera achapfeka magirovhosi e-anti-static paanobudisa zvinhu uye kuedza IQC, uye chiridzwa chichave chakavimbika pasi, uye chigadziro chekushanda chichave chakagadzirwa ne-anti-static rubber pad mberi.

2. Mukuita basa, anti-static worktops inoshandiswa, uye anti-static containers inoshandiswa kubata zvikamu uye semi-yakapera zvigadzirwa. Midziyo yekushongedza yeDhipatimendi inogona kudzikiswa, uye simbi yemagetsi inosungirirwa inoda kuve yemhando ye-anti-static. Midziyo yese inofanirwa kuongororwa isati yashandiswa.

3. Kana PCBA ichigadziriswa nemuchoto, nekuti mapini eplug-in zvinhu anogezwa nekuyerera kwerata, zvimwe zvinhu zveplug-in zvinorereka mushure mewelding, zvichikonzera kuti chikamu chemuviri chipfuure sirika skrini. Naizvozvo, vashandi vekugadzirisa welding mushure mechoto cherata vanodiwa kuti vagadzirise nemazvo.

4. Kana PCBA iri welding nyanga uye bhatiri, zvichaonekwa kuti solder joint haizove yakawandisa, iyo isingazokonzeri kupfupika kana kudonha kubva kune yakapoteredza zvikamu.

5. PCBA substrates ichaiswa zvakatsvinda, uye mahwendefa akashama haagone kurongedzerwa zvakananga. Kana stacking ichidikanwa, ichaiswa mumabhegi e electrostatic.

Chengetedzo yePCBA yapera chigadzirwa kusangana

1. Muchina wose usina shell unoshandisa anti-static packaging bag

Gara uchiongorora maturusi e-anti-static, zvigadziriso uye zvinhu kuti uone kuti nyika inoshanda inosangana nezvinodiwa.

2. Pakuunganidza zvigadzirwa zvakapedzwa, tevera nzira dzinotevera

Warehouse → mutsara wekugadzira → mutsara wekugadzira kusimudzira software → kuungana mumuchina wakakwana → QC bvunzo → nyora IMEI nhamba → QA yakazara kuongorora → kudzoreredza marongero efekitori → imba yekuchengetera zvinhu; Iyo software ichakwidziridzwa isati yasangana. Haikwanise kuunganidzwa mumuchina wapera uye wozokwidziridzwa. Iyo inogona kusakwidziridzwa nekuda kweiyo isina kunaka welding, pfupi dunhu, mashandiro ekuita matambudziko, nezvimwe, zvichikonzera kukanganisa kwePCBA yakaipa.

Izvo zviri pamusoro ndizvo zvinoda kutariswa muPCBA kugadzirisa? PCBA kugadzirisa inoda kuterera kuunzwa kwemapoinzi, ndinovimba inogona kukubatsira.