- 25

- Mar

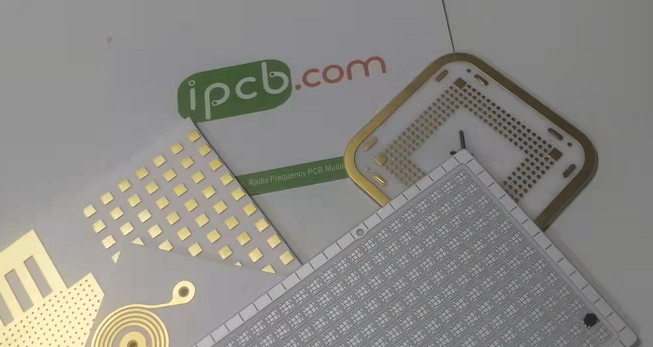

Alumina seramiiki PCB

Gịnị bụ kpọmkwem ngwa nke alumina seramiiki mkpụrụ

Na PCB proofing, alumina ceramic substrate ejirila ọtụtụ ụlọ ọrụ. Otú ọ dị, na ngwa ndị a kapịrị ọnụ, ọkpụrụkpụ na nkọwapụta nke ihe ọ bụla alumina ceramic substrate dị iche. Gịnị kpatara nke a?

1. A na-ekpebi oke nke alumina ceramic substrate dị ka ọrụ nke ngwaahịa ahụ si dị

The thicke ọkpụrụkpụ nke alumina seramiiki mkpụrụ, mma ike na ike na nrụgide nguzogide, ma thermal conductivity dị njọ karịa nke mkpa; N’ụzọ megidere nke ahụ, nke alumina ceramic substrate nke dị gịrịgịrị, ike na nguzogide nrụgide adịghị ike dị ka ndị siri ike, mana conductivity thermal dị ike karịa ndị gbara ọkpụrụkpụ. The ọkpụrụkpụ nke alumina seramiiki mkpụrụ bụ n’ozuzu 0.254mm, 0.385mm na 1.0mm / 2.0mm / 3.0mm / 4.0 mm, wdg.

2. Nkọwa na nha nke alumina ceramic substrates dịkwa iche

N’ozuzu, alumina seramiiki mkpụrụ dị nnọọ nta karịa nkịtị PCB osisi n’ozuzu, na size bụ n’ozuzu ọ dịghị ihe karịrị 120mmx120mm. Ndị gafere nha a n’ozuzu kwesịrị ịhazi ya. Na mgbakwunye, nha nke alumina ceramic substrate abụghị nke ka mma, ọkachasị n’ihi na ejiri seramiki mee mkpụrụ ya. Na usoro nke PCB proofing, ọ dị mfe iduga na efere efere, na-akpata ọtụtụ ihe mkpofu.

3. Ọdịdị nke alumina ceramic substrate dị iche

Ngwa seramiiki alumina na-abụkarị otu efere nwere akụkụ abụọ, nwere akụkụ anọ, square na okirikiri. Na PCB proofing, dị ka usoro chọrọ, ụfọdụ nwekwara mkpa ime grooves na seramiiki mkpụrụ na dam mechie usoro.

Njirimara nke mkpụrụ osisi seramiiki alumina gụnyere:

1. Nchegbu siri ike na ọdịdị kwụsiri ike; Elu ike, elu thermal conductivity na elu mkpuchi; Adhesion siri ike na mgbochi corrosion.

2. Ọrụ okirikiri okpomọkụ dị mma, yana usoro 50000 na ntụkwasị obi dị elu.

3. Dị ka PCB osisi (ma ọ bụ IMS mkpụrụ), ọ nwere ike etch Ọdịdị nke dị iche iche ndịna-emeputa; Enweghị mmetọ na mmetọ.

4. Oke okpomọkụ na-arụ ọrụ: – 55 ℃ ~ 850 ℃; Ọnụ ọgụgụ nke mgbasawanye ọkụ dị nso na silicon, nke na-eme ka usoro mmepụta nke modul ike dị mfe.

Kedu uru nke alumina ceramic substrate?

A. The thermal mgbasa ọnụọgụ ọnụọgụ nke seramiiki mkpụrụ dị nso na nke silicon mgbawa, nke nwere ike ichekwa mgbanwe oyi akwa Mo mgbawa, zọpụta ọrụ, ihe na ibelata ọnụ ahịa;

B. Welding oyi akwa, belata thermal iguzogide, belata oghere ma melite mkpụrụ;

C. The akara obosara nke 0.3mm oké ọla kọpa foil bụ nanị 10% nke nkịtị e biri ebi sekit osisi;

D. The thermal conductivity nke mgbawa na-eme ka ngwugwu nke mgbawa dị nnọọ kọmpat, nke na-eme ka ike njupụta nke ukwuu na-eme ka ntụkwasị obi nke usoro na ngwaọrụ dịkwuo mma;

E. Ụdị (0.25mm) seramiiki mkpụrụ nwere ike dochie BeO na-enweghị nsị gburugburu ebe obibi;

F. Large, 100A ugbu a nọgidere na-agafe 1mm obosara na 0.3mm oké ọla kọpa ahu, na okpomọkụ ịrị elu bụ banyere 17 ℃; 100A ugbu a nọgidere na-agafe 2mm n’obosara na 0.3mm oké ọla kọpa ahu, na okpomọkụ ịrị elu bụ nanị banyere 5 ℃;

G. Dị ala, 10 × The thermal resistance of 10mm ceramic substrate, 0.63mm thick ceramic substrate, 0.31k / w, 0.38mm thick ceramic substrate na 0.14k / w n’otu n’otu;

H. Nguzogide nrụgide dị elu, na-eme ka nchekwa nke onwe na ikike nchebe ngwá ọrụ;

1. Ghọta nkwakọ ngwaahịa ọhụrụ na ụzọ mgbakọ, nke mere na ngwaahịa ndị ahụ na-ejikọta nke ọma ma na-ebelata olu.