- 06

- Oct

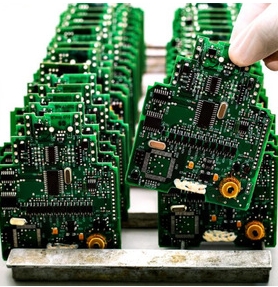

Ungathintela njani izehlo ezintandathu zonxibelelwano ngetini kwibhodi yesekethe emva kokujijisiswa ngamaza.

Ungayithintela njani izehlo ezintandathu zonxibelelwano ngetini ibhodi yesekethe emva kokutsalwa kwamaza.

1. Ngenxa yesenzeko soqhagamshelo lwe-tin olubangelwa li-pin yecandelo elide kakhulu ngexesha le-soldering yebhodi yesekethe, kuya kuhlawulwa ingqalelo kubude be-pin yecandelo ngokubanzi yi-1.5-2mm, engayi kubakho ukuba ayidluli kubude .

2. Ngenxa yokuba uyilo lwenkqubo ye-PCB luyinkimbinkimbi ngakumbi kwaye isithuba se-pin esikhokelayo sixinene ngakumbi, imeko yokuxhuma kwe-tin emva kokuba i-wave soldering yenzeka. Ukutshintsha uyilo lwephedi sisisombululo. Umzekelo, ukunciphisa ubungakanani bephedi, ukwandisa ubude bephedi ephuma kwicala lokutshangatshangisa, ukwandisa umsebenzi wokuhamba / ukunciphisa ubude bolwandiso olukhokelayo zizisombululo.

3. Emva kokujijisiswa ngumtshangatshangiso, inkcenkce etyhidiweyo ingena kumphezulu webhodi yesekethe ukwenza uxhulumaniso lwenkcenkce phakathi kwezikhonkwane zento leyo. Esona sizathu siphambili sale nto kukuba ububanzi bepali engenanto bukhulu kakhulu, okanye ububanzi bangaphandle bephini yecandelo bincinci kakhulu.

4. I-wave crest eyenziwe ngamalungu eenyawo ezishinyeneyo kwiindawo ezimbini idityaniswe ne-tin emva kwentsimbi.

5. I-Wave soldering nge-tin ngenxa yobungakanani bepad obugqithisileyo.

6. Ukudityaniswa kweTin kwezikhonkwane zecandelo emva kokujijiswa kwamaza ngenxa yokuthengiswa gwenxa kwezikhonkwane zecandelo.

Indlela yokuthintela uqhagamshelo lwe-tin kwibhodi yesekethe emva kwe-soldering wave.

1.Ukuyilwa ngokweenkcukacha zoyilo zePCB. I-axis ende yeetshipsi ezimbini zokuphela ziya kuthi zijolise kwicala le-welding, kwaye i-axis ende ye-SOT kunye ne-SOP iya kufana nesikhokelo se-welding. Yandisa iphedi yepini yokugqibela ye-SOP (uyile iphedi ye-solder);

2. Izikhonkwane zezinto ezifakiweyo ziya kwenziwa ngokokuqhekeka kwemingxunya kunye neemfuno zebhodi eshicilelweyo. Ukuba inkqubo yokufakelwa okufutshane ifakelwe, izikhonkwane zentsimbi kwindawo yokudibanisa ziya kutyhilwa kumphezulu webhodi eprintiweyo nge-0.8 ~ 3mm, kwaye umzimba wecandelo uya kuthi nkqo ngexesha lokufakwa;

3.Seta ubushushu bokufudumeza ngokobungakanani bePCB, nokuba ngaba kukho iibhodi ze-multilayer, inani lezinto, inani lezinto ezixhonyiweyo, njl.

4. Ubushushu tin wave yi 250 ± 5 ℃, kunye nexesha iwelding yi 3 ~ 5S. Xa iqondo lobushushu lisezantsi kancinane, isantya sebhanti yokuhambisa kufuneka sicothe;

5. Buyisela ukubhobhoza.