- 04

- Oct

Gudanar da tsarin sarrafawa mai mahimmanci don babban allon kewaye

Babban darajar PCB gabaɗaya an bayyana shi azaman yadudduka 10 – yadudduka 20 ko fiye na high Multi-Layer kewaye hukumar. Yana da wahalar aiwatarwa fiye da allon kewayawa na gargajiya da yawa, kuma buƙatun inganci da amintattu suna da yawa. An fi amfani da shi a cikin kayan sadarwa, manyan sabobin sabo, kayan aikin likitanci, jirgin sama, sarrafa masana’antu, sojoji da sauran fannoni. A cikin shekarun baya-bayan nan, bukatar babbar hukumar jirgi a cikin sadarwa mai amfani, tashar tushe, jirgin sama, sojoji da sauran fannoni har yanzu suna da karfi, kuma tare da saurin ci gaban kasuwar kayan aikin sadarwa na kasar Sin, fatan samun babbar kasuwar jirgi na da alfanu. .

A halin yanzu, manyan masana’antun PCB masu girma a China musamman sun fito ne daga kamfanonin da kasashen waje ke tallafawa ko kuma wasu kananan kamfanoni na cikin gida. Samar da katafaren hukumar da’irar ba kawai yana buƙatar fasaha mafi girma da saka hannun jari na kayan aiki ba, har ma yana buƙatar tara ƙwarewar ma’aikatan fasaha da ma’aikatan samarwa. A lokaci guda, shigo da manyan takaddun takaddun takaddar abokin ciniki na katako yana da tsauri kuma mai rikitarwa, don haka babban allon kewayawa yana shiga kasuwancin tare da ƙofar mafi girma, kuma tsarin samar da masana’antu ya daɗe. Matsakaicin adadin yadudduka na PCB ya zama muhimmin ma’aunin fasaha don auna matakin fasaha da tsarin samfuran kamfanonin PCB. Wannan takarda a taƙaice ta bayyana manyan matsalolin aiki da aka gamu da su a cikin samar da babban kwamiti mai kewaye, kuma yana gabatar da mahimman abubuwan sarrafawa na mahimmin tsarin samar da babban allon kewaya don yin tunani.

Na ɗaya, manyan matsalolin samarwa

Idan aka kwatanta da halayen samfuran katako na al’ada, babban allon kewayawa yana da halayen sassan katako masu kauri, ƙarin yadudduka, ƙarin layuka da ramuka masu girma, girman raka’a mafi girma, matsakaicin matsakaici, da sauransu, da sararin samaniya, inter -jeri na layi, sarrafa rashin ƙarfi da buƙatun dogaro sun fi tsauri.

1.1 Wahala na daidaitawa tsakanin interlayer

Saboda yawan adadin yadudduka na katako mai tsayi, ƙarshen ƙirar abokin ciniki yana da ƙarin buƙatu masu tsauri akan daidaita layin PCB. Yawancin lokaci, juriya jeri tsakanin yadudduka ana sarrafa shi ya zama ± 75μm. La’akari da babban girman ƙirar babban allo, yanayin zazzabi da zafi na bitar canja wurin hoto, da rarrabuwa ta ɓarna sakamakon rashin daidaituwa da ƙuntatawa na yadudduka daban-daban na katako, yanayin sakawa tsakanin yadudduka da sauran dalilai, Yana ya sa ya fi wahalar sarrafa daidaitawa tsakanin yadudduka na babban jirgin.

1.2 Wahala wajen yin da’irar ciki

Babban jirgin sama yana ɗaukar kayan aiki na musamman kamar babban TG, babban gudu, babban mita, jan ƙarfe mai kauri, matsakaicin matsakaici, da sauransu, wanda ke gabatar da manyan buƙatu akan ƙirar kewaya ta ciki da sarrafa girman hoto, kamar amincin rashin ƙarfi. watsa sigina, wanda ke ƙara wahalar ƙirar kewaya ta ciki. Nisa layin layin nisa ƙarami ne, buɗe ƙaramin kewaya mai buɗewa, ƙaramin ƙaramin ƙarami, ƙarancin wucewa; Akwai ƙarin yadudduka na sigina a cikin layin mai kauri, kuma yuwuwar gano ɓoyayyen AOI a cikin rufin ciki yana ƙaruwa. A kauri daga cikin ciki farantin ciki ne na bakin ciki, sauki ninka saboda sakamakon matalauta daukan hotuna, sauki mirgine farantin lokacin etching; Yawancin allon hawa masu hawa sune allon tsarin, kuma girman naúrar yana da girma, don haka farashin ƙarar samfurin da aka gama yana da inganci.

1.3 Wahalar aikin latsawa

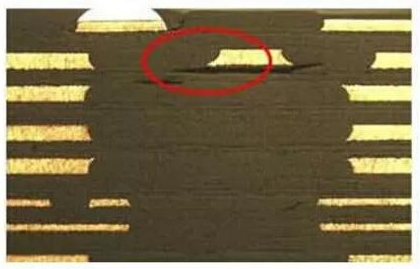

Yawancin faranti na ciki da faranti masu warkarwa sun mamaye, kuma lahani kamar farantin faifai, lamination, ramin resin da sauran kumfa ana samun sauƙin samarwa yayin latsawa. A cikin ƙirar tsarin laminated, ya zama dole a yi la’akari da cikakken juriya na kayan, juriya na ƙarfin wuta, adadin manne da kaurin matsakaici, kuma saita shirin matse farantin faranti mai ƙarfi. Saboda babban adadin yadudduka, faɗaɗawa da raguwar ikon sarrafawa da girman diyya ba zai iya kiyaye daidaituwa ba; Launin rufi na bakin ciki tsakanin yadudduka cikin sauƙi yana haifar da gazawar gwajin aminci tsakanin yadudduka. Hoto na 1 shine ƙirar lahani na fashewar farantin farantin bayan gwajin danniyar zafi.

1.4 Matsaloli masu wahala a hakowa

Ana amfani da faranti na jan ƙarfe na musamman tare da babban TG, babban gudu, babban mita da kauri mai kauri don haɓaka wahalar hakowa, burr da gurɓatawa. Yawan yadudduka, kaurin jan ƙarfe da kaurin farantin, mai sauƙin karya hako wuka; Rashin nasarar CAF ta hanyar BGA mai yawa da tazarar bangon rami mai zurfi; Kaurin farantin zai iya haifar da matsala cikin hakowa.

Ii. Sarrafa mahimman hanyoyin samarwa

2.1 Zaɓin kayan

Tare da babban aikin sarrafawa don abubuwan lantarki, ƙarin aiki a cikin jagorar ci gaba, a lokaci guda tare da babban mita, haɓaka saurin watsa siginar siginar, don haka kayan aikin lantarki na lantarki na yau da kullun da asarar dielectric yayi ƙasa, da ƙarancin CTE, ƙarancin ruwa sha da babban aikin jan ƙarfe da aka lulluɓe da shi mafi kyau, don gamsar da buƙatun babban aikin farantin da aminci. Masu ba da farantin da aka saba amfani da su sun haɗa da jerin A, jerin B, jerin C da D jerin. Dubi Jigo na 1 don kwatancen manyan halayen waɗannan madaidaitan ciki guda huɗu. Don saman tsaka -tsakin tsaka -tsakin ƙarfe na katako na jan ƙarfe yana zaɓar babban abun ciki na resin, rabi na tsaka -tsakin tsayayyiyar kwararar resin ya isa ya cika zane -zane, Layer dielectric ya yi kauri sosai don bayyana ƙarar faranti mai kauri, yayin da slants na bakin ciki, Layer dielectric yana da sauƙi don haifar da matsakaicin matsakaici, gazawar gwajin matsin lamba kamar matsalar inganci, don haka zaɓin kayan mutuƙar lantarki yana da mahimmanci.

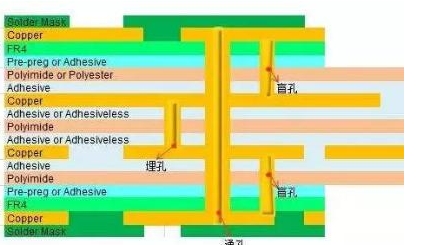

2.2 Laminated tsarin zane

A cikin ƙirar tsarin laminated, manyan abubuwan da za a yi la’akari da su shine juriya mai zafi na kayan, juriya na ƙarfin lantarki, adadin manne da kaurin matsakaicin Layer, da sauransu yakamata a bi manyan ƙa’idodi masu zuwa.

(1) Yankin da aka warkar da rabi da mai ƙera faranti dole ne su kasance daidai. Domin tabbatar da amincin PCB, duk yadudduka na allunan da aka warkar da su yakamata su guji amfani da Allunan guda ɗaya na 1080 ko 106 (ban da buƙatun musamman na abokan ciniki). Lokacin da babu buƙatar matsakaicin kauri, kaurin matsakaici tsakanin yadudduka ya zama ≥0.09mm bisa ga IPC-A-600g.

(2) Lokacin da abokin ciniki ke buƙatar babban farantin TG, babban farantin da farantin warkarwa yakamata suyi amfani da babban kayan TG daidai.

(3) substrate na ciki 3OZ ko sama, zaɓi babban abun ciki na allunan da aka warkar da su, kamar 1080R/C65%, 1080HR/C 68%, 106R/C 73%, 106HR/C76%; Koyaya, ƙirar tsarin zanen gado guda 106 tare da babban manne yakamata a guji shi gwargwadon iko don hana haɗewa da yawa na zanen warkarwa 106. Saboda zaren fiber ɗin gilashi ya yi ƙanƙara sosai, rushewar yarn fiber ɗin gilashi a cikin babban yanki na ƙasa zai shafi kwanciyar hankali da lamination na farantin fashewa.

(4) Idan abokin ciniki ba shi da buƙatu na musamman, juriya mai kauri na matsakaiciyar interlayer gaba ɗaya ana sarrafa ta +/- 10%. Don farantin impedance, haƙuri mai kauri na matsakaici ana sarrafa shi ta IPC-4101 C/M haƙuri. Idan abubuwan da ke haifar da rashin daidaituwa suna da alaƙa da kaurin substrate, dole ne a sarrafa haƙurin farantin ta IPC-4101 C/M.

2.3 Sarrafa jeri na Interlayer

Daidaitaccen diyyar girman babban ɓangaren ciki da sarrafa girman girman samarwa yana buƙatar dogara ne akan bayanai da bayanan tarihin da aka tattara a cikin samarwa a cikin wani lokaci don daidai rama girman hoto na kowane Layer na babban kwamitin don tabbatar da daidaituwa. faɗaɗawa da ƙanƙancewa na kowane Layer na babban kwamitin. Zaɓi madaidaiciyar madaidaiciya kuma madaidaiciyar madaidaiciyar madaidaiciyar madaidaiciyar madaidaiciya kafin latsawa, kamar saka wuri huɗu (Pin LAM), narke mai zafi da haɗin rivet. Mabuɗin don tabbatar da ingancin latsawa shine saita tsarin matsi da ya dace da kuma kula da aikin jarida na yau da kullun, sarrafa manne matsi da tasirin sanyaya, da rage matsalar rarrabuwa tsakanin yadudduka. Ana buƙatar yin la’akari da kulawar daidaitawa ta Interlayer gabaɗaya daga ƙimar diyya na ciki, latsa yanayin sakawa, sigogin tsari, kayan kadara da sauran abubuwan.

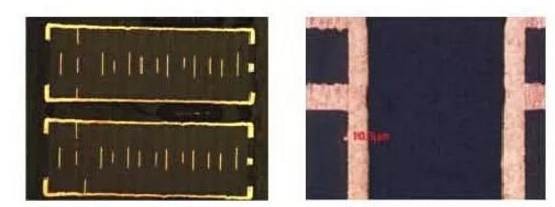

2.4 Tsarin layin ciki

Saboda ƙarfin nazari na injin fallasa na gargajiya ya kusan 50μm, don samar da babban kwamiti, ana iya gabatar da hoton kai tsaye na laser (LDI) don haɓaka ƙarfin nazarin hoto, ƙarfin nazari na kusan 20μm. Daidaitaccen daidaituwa na injin watsawa na gargajiya shine ± 25μm, kuma daidaiton daidaitawar interlayer ya fi 50μm. Za’a iya inganta daidaiton jadawali zuwa kusan 15μm kuma ana iya sarrafa madaidaicin matsayin interlayer a cikin 30μm ta amfani da injin ƙimar madaidaiciyar madaidaiciya, wanda ke rage karkacewar matsayi na kayan aikin gargajiya kuma yana inganta daidaiton daidaiton interlayer. jirgi.

Domin haɓaka ikon yin layi, ya zama dole a ba da diyya mai dacewa ga faɗin layin da kushin (ko zoben walda) a cikin ƙirar injiniya, amma kuma ana buƙatar yin ƙarin ƙira na ƙira akan adadin diyya na musamman zane -zane, kamar madauki kewaye, kewaye mai zaman kansa da sauransu. Tabbatar ko diyya ƙira don faɗin layin ciki, nisan layi, girman zobe kadaici, layi mai zaman kansa, nisan rami zuwa layi yana da ma’ana, ko canza ƙirar injiniya. Tsarin ƙira da rashin amsawa yana buƙatar kulawa ko biyan diyya na layin mai zaman kansa da layin rashin ƙarfi ya isa. Ana sarrafa sigogi da kyau yayin etching, kuma ana iya samar da yanki na farko bayan an tabbatar da cancanta. Don rage lalacewar lalacewar gefen gefen, ya zama dole a sarrafa abun da ke cikin maganin etch a cikin mafi kyawun kewayon. Kayan aikin layi na gargajiya ba shi da isasshen ikon yin toshe, don haka ana iya canza kayan aikin ta hanyar fasaha ko shigo da su cikin madaidaicin kayan aikin layin dogo don inganta daidaiton etching, rage ɓoyayyen ɓarna, ƙazantar ƙazanta da sauran matsaloli.

2.5 Tsarin dannawa

A halin yanzu, hanyoyin saka interlayer kafin latsa galibi sun haɗa da: Matsayin rami huɗu (Pin LAM), narke mai zafi, rivet, narkewar zafi da haɗin rivet. Tsarin samfuran daban -daban suna ɗaukar hanyoyin sakawa daban -daban. Don manyan faranti, matsayi na rami huɗu (Pin LAM), ko fusion + riveting, OPE yana fitar da ramukan matsayi tare da daidaitaccen sarrafawa zuwa ± 25μm. A lokacin samar da tsari, ya zama dole a bincika ko an haɗa kowane farantin a cikin naúrar don hana ɓarna na gaba. Kayan latsawa yana ɗaukar babban goyan bayan goyan baya don saduwa da daidaiton daidaitawar interlayer da amincin farantin mai tsayi.

Dangane da babban farantin laminated tsarin da kayan da aka yi amfani da su, hanyoyin latsawa da suka dace, saita mafi kyawun ƙimar dumama da lanƙwasa, akan hanyoyin latsa PCB na multilayer na yau da kullun, ya dace don rage ƙimar murfin ƙarfe na ƙarfe, tsawaita lokacin warkar da zafin jiki, yi Gudun ruwa, warkewa, a lokaci guda ku guji kan katako a yayin latsawa, matsalar ƙaura tsakanin interlayer. Darajar TG abu ba ɗaya ba ce, ba za ta iya zama allon gira ɗaya ba; Ba za a iya haɗa sigogi na al’ada na jirgi tare da sigogi na musamman na hukumar ba; Don tabbatar da fa’idar faɗaɗawa da ƙuntatawa, aikin faranti daban-daban da zanen gado mai warkewa daban ne, kuma yakamata a yi amfani da sigogin takaddar warkarwa mai dacewa don latsawa, kuma kayan musamman waɗanda ba a taɓa amfani da su ba suna buƙatar tabbatar da tsarin sigogi.

2.6 Tsarin hakowa

Saboda fifikon kowane juzu’i, farantin da murfin jan ƙarfe suna da kauri sosai, wanda ke haifar da lalacewa mai ƙarfi akan bitar rami kuma yana da sauƙi don karya kayan aikin rawar. Yawan ramuka, saurin faɗuwa da saurin juyawa yakamata a saukar da su yadda yakamata. Daidaita daidai da faɗaɗa da ƙuntata farantin, yana ba da daidaitaccen daidaituwa; Yawan yadudduka ≥14, ramin rami ≤0.2mm ko rami zuwa layin nesa ≤0.175mm, amfani da daidaiton rami production0.025mm samar da rawar soja; Ana amfani da hakowa na mataki don diamita φ4.0mm ko sama, ana amfani da hakowa mataki don kauri zuwa rabo diamita 12: 1, kuma ana amfani da hakowa mai kyau da mara kyau don samarwa. Sarrafa hakowa gaban da rami diamita. Yi ƙoƙarin amfani da sabon wuka mai rami ko niƙa wuka 1 don ratsa babban jirgin. Ya kamata a sarrafa diamita na rami tsakanin 25um. Don warware matsalar burr na hako rami na farantin ƙarfe mai kauri a cikin babban matakin, an tabbatar da shi ta hanyar gwajin gwaji cewa yin amfani da babban farantin ƙarfe, adon farantin lamba ɗaya ne kuma ana sarrafa lokacin niƙa bitar cikin sau 3 zai iya inganta burr ramin hakowa

Don babban mita, saurin gudu da watsa bayanai na babban jirgi, fasahar hakowa ta baya hanya ce mai inganci don haɓaka amincin sigina. Rawar baya galibi tana sarrafa tsayin ragowar ragowar, daidaiton wurin rami tsakanin ramukan hakowa biyu da waya na jan ƙarfe a cikin ramin. Ba duk kayan aikin driller suna da aikin hakowa na baya ba, ya zama dole don aiwatar da haɓaka fasaha na kayan driller (tare da aikin hakowa na baya), ko siyan dillali tare da aikin hakowa na baya. Hanyoyin hakowa na baya da aka yi amfani da su a cikin adabin masana’antu masu dacewa da kuma samar da taro da yawa sun haɗa da: zurfin sarrafa madaidaiciyar hanyar hakowa, hakowa ta baya tare da layin amsa sigina a cikin sashin ciki, lissafin zurfin hakowa daidai gwargwado na kaurin farantin, wanda ba zai a sake nan.

Uku, gwajin dogaro

The babban matakin jirgi gabaɗaya tsarin jirgi ne, ya yi kauri fiye da allon multilayer na al’ada, mafi nauyi, girman raka’a mafi girma, ƙarfin zafin da ya dace shima ya fi girma, a cikin walda, buƙatar ƙarin zafi, lokacin zafi mai zafi yana da tsawo. Yana ɗaukar sakan 50 zuwa 90 a 217 ℃ (wurin narkewa na tin-silver-copper solder), kuma saurin sanyaya babban farantin faranti yana da ɗan jinkiri, don haka an ƙara lokacin gwaji na walda na reflow. A hade tare da ipC-6012C, IPC-TM-650 matsayin da buƙatun masana’antu, an bayyana babban gwajin dogaro da farantin mai tsayi a cikin Table 2.

Table2