- 04

- Oct

Tsamaiso ea ts’ebetso ea senotlolo bakeng sa boto ea potoloho e phahameng

Boemo bo phahameng PCB ka kakaretso e hlalosoa e le mekhahlelo e 10 – likarolo tse 20 kapa ho feta ea boto e phahameng ea mekato e mengata. Ho thata haholo ho e sebetsana ho feta boto ea potoloho ea mekato e mengata, ‘me litlhoko tsa eona tsa boleng le ho ts’epahala li holimo. E sebelisoa haholo-holo lisebelisoa tsa puisano, lisebelisoa tse phahameng, lisebelisoa tsa bongaka tsa bongaka, ho fofa, taolo ea indasteri, sesole le likarolo tse ling. Lilemong tsa morao tjena, tlhoko ea ‘maraka oa boto e phahameng lipuisanong tse sebelisitsoeng, seteisheneng sa lifofane, mabotho a sesole, masimong le libakeng tse ling e ntse e le matla, mme ka kholo e potlakileng ea mmaraka oa China oa lisebelisoa tsa mehala, tebello ea mmaraka oa boto e phahameng e ts’episa .

Hajoale, tlhahiso e kholo ea baetsi ba maemo a phahameng a PCB Chaena e tsoa likhoebong tse tšehelitsoeng ka lichelete kantle ho naha kapa ho likhoebo tse nyane tsa lehae. Tlhahiso ea boto ea potoloho ea boemo bo holimo ha e hloke feela tsetelo e phahameng ea mahlale le lisebelisoa, empa hape e hloka pokello ea boiphihlelo ba basebetsi ba tekheniki le basebetsi ba tlhahiso. Ka nako e ts’oanang, ho kenella ha lits’ebetso tsa boemo bo holimo ba boto ea setifikeiti ho thata ebile ho boima, ka hona boto ea potoloho e phahameng e kena khoebong ka monyako o phahameng, mme potoloho ea tlhahiso ea indasteri e telele. Palo e karolelano ea likarolo tsa PCB e se e le letšoao la bohlokoa la tekheniki ho lekanya boemo ba tekheniki le sebopeho sa sehlahisoa sa likhoebo tsa PCB. Pampiri ena e hlalosa ka bokhutšoanyane mathata a mantlha a ts’ebetso a kopaneng le ona tlhahiso ea boto ea potoloho e phahameng, ‘me e hlahisa lintlha tsa taolo ea ts’ebetso ea senotlolo sa tlhahiso ea boto ea potoloho ea boemo bo holimo bakeng sa ts’upiso ea hau.

E ‘ngoe, mathata a mantlha a tlhahiso

Ha e bapisoa le litšobotsi tsa lihlahisoa tse tloaelehileng tsa boto ea potoloho, boto ea potoloho ea boemo bo holimo e na le litšobotsi tsa likarolo tse tenya tsa boto, likarolo tse ling, mela e teteaneng le masoba, boholo ba yuniti, lera le lesesaane, joalo-joalo, le sebaka se kahare, inter ho tsamaellana -layer, taolo ea impedance le litlhoko tsa ts’epahalo li thata haholo.

1.1 Bothata ba tatellano ea li-interlayer

Ka lebaka la palo e kholo ea likarolo tse phahameng tsa boto, pheletso ea moreki e na le litlhoko tse thata le ho feta mabapi le tatellano ea likarolo tsa PCB. Hangata, mamello ea tatellano lipakeng tsa likarolo e laoloa ho ba ± 75μm. Ha ho nahanoa ka boholo bo boholo ba moralo oa li-board tse phahameng, thempereichara le mongobo oa likopano tsa phetiso e hlakileng, le boits’oaro ba dislocation bo bakiloeng ke ho se lumellane ha katoloso le khutsufatso ea likarolo tse fapaneng tsa boto, boemo ba boemo lipakeng tsa likarolo le lintlha tse ling, e etsa hore ho be thata le ho feta ho laola khokahano lipakeng tsa likarolo tsa boto e phahameng.

1.2 Mathata a ho etsa potoloho ea kahare

Boto e phahameng e amohela lisebelisoa tse ikhethang joalo ka TG e phahameng, lebelo le phahameng, maqhubu a phahameng, koporo e teteaneng, lera le tšesaane le bolelele, jj. phetiso ea lets’oao, e eketsang bothata ba ho qhekella ha potoloho ea kahare. Mohala oa bophara ba mola o monyane, keketseho e khuts’oane ea potoloho, keketseho e nyane ea sekhahla, sekhahla se tlase sa ho feta; Ho na le likarolo tse ling tsa matšoao moleng o teteaneng, mme menyetla ea ho se fumanehe ha AOI karolong e ka hare ea keketseho. Botenya ba poleiti ea kahare ea mantlha e tšesaane, e bonolo ho e mena ka lebaka la ho pepeseha hampe, ho le bonolo ho phuthela poleiti ha e cheka; Boholo ba mapolanka a phahameng ke liboto tsa sistimi, ‘me boholo ba yuniti bo boholo, ka hona litjeo tsa lihlahisoa tsa sehlahisoa se felileng li holimo haholo.

1.3 Bothata ba tlhahiso e hatellang

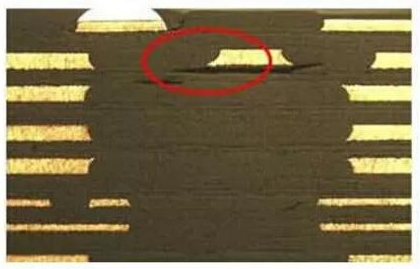

Lipoleiti tse ngata tsa kahare tsa mantlha le lipoleiti tse sa phekolehang li phahamisitsoe, ‘me likoli tse kang slide poleiti, lamination, resin cavity le masale a bubble li hlahisoa habonolo nakong ea tlhahiso e hatellang. Moralong oa sebopeho se laminated, ho hlokahala hore o nahane ka botlalo ka ts’ireletso ea mocheso oa thepa, ho hanela motlakase, boholo ba sekhomaretsi le botenya ba sehare, ebe o beha lenaneo le utloahalang la ho phahamisa poleiti e phahameng. Ka lebaka la palo e kholo ea mekhahlelo, taolo ea katoloso le shrinkage le puseletso ea coefficient ha e khone ho boloka botsitso; Lera le lesesaane la ho koala lipakeng tsa likarolo habonolo le lebisa ho hloleheng ha tlhahlobo ea ts’epahalo lipakeng tsa likarolo. Setšoantšo sa 1 ke setšoantšo se nang le sekoli sa ho phatloha ha poleiti kamora teko ea khatello ea maikutlo.

1.4 Lintlha tse thata ho cheka

Lipoleiti tse khethehileng tsa koporo tse nang le TG e phahameng, lebelo le phahameng, maqhubu a phahameng le botenya bo boholo li sebelisoa ho eketsa bothata ba ho cheka bohale, burr le ho silafatsa. Palo ea le dikarolo, palo yohle botenya ba koporo le poleiti botenya, ho le bonolo ho roba thipa cheka; Ho hloleha ha CAF ho bakoa ke BGA e teteaneng le sebaka se moqotetsane sa mabota a masoba; Botenya ba poleiti bo ka lebisa habonolo bothateng ba ho cheka skew.

Ii. Taolo ea lits’ebetso tsa bohlokoa tsa tlhahiso

Khetho ea Boitsebiso

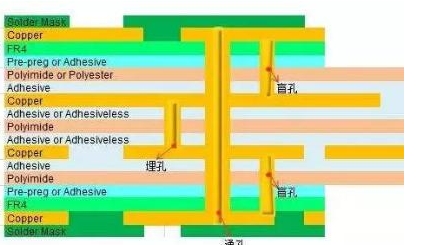

Ka ts’ebetso e phahameng ea ts’ebetso ea likarolo tsa elektroniki, e sebetsang haholoanyane ntlheng ea nts’etsopele, ka nako e ts’oanang le maqhubu a phahameng, nts’etsopele e phahameng ea phetiso ea lets’oao, ka hona tahlehelo ea motlakase ea dielectric khafetsa le tahlehelo ea dielectric e tlase, mme CTE e tlase, metsi a tlase absorption le phahameng tshebetso koporo clad lintho tse bonahalang molemo, ho khotsofatsa tlhokahalo ea sebetsa poleiti holimo le ho tšepahala. Barekisi ba lipoleiti ba neng ba sebelisoa hangata ba kenyelletsa letoto la A, B letoto la lihlooho tse, C letoto la lihlooho tse le D letoto la lihlooho tse. Bona Tafole 1 bakeng sa papiso ea litšobotsi tsa mantlha tsa substrate ena e ka hare e mene. Bakeng sa holimo botenya ba halofo e tiileng ea boto ea potoloho ea koporo e khetha lehoakhoa le phahameng, karolo ea interlayer ea solidification ea lehoakhoa e lekane ho tlatsa lits’oants’o, lera la dielectric le teteaneng haholo ho le bonolo ho hlaha poleiti e feliloeng e le tenya haholo, athe li-slants tse tšesaane, lera la dielectric li bonolo ho fella ka mekhahlelo e mahareng, ho hloleha ha liteko tse phahameng joalo ka bothata ba boleng, ka hona khetho ea lisebelisoa tsa dielectric e bohlokoa haholo.

Moralo oa sebopeho sa Laminated

Moralo oa sebopeho sa laminated, lintlha tsa mantlha tse lokelang ho nahanoa ke ho hanyetsa mocheso oa thepa, ho hanyetsa motlakase, bongata ba sekhomaretsi le botenya ba lera le mahareng, jj. Melao-motheo e latelang e lokela ho lateloa.

(1) Sengoathoana se phekotsoeng habeli le moetsi oa poleiti ea mantlha li tlameha ho ts’oana. Bakeng sa ho netefatsa ho ts’epahala ha PCB, likarolo tsohle tsa matlapa a phekotsoeng li lokela ho qoba ho sebelisa lipilisi tse le ‘ngoe tse phekotsoeng ka 1080 kapa 106 (ntle le litlhoko tse ikhethileng tsa bareki). Ha ho se na tlhoko ea botenya bo mahareng, botenya ba mahareng lipakeng e lokela ho ba -0.09mm ho latela IPC-A-600g.

(2) Ha moreki a hloka poleiti e phahameng ea TG, poleiti ea mantlha le poleiti e phekotsoeng habeli li lokela ho sebelisa thepa e phahameng ea TG.

(3) Karolo e ka hare ea 3OZ kapa kaholimo, khetha likarolo tse phahameng tsa lehoakhoa tsa matlapa a phekotsoeng, joalo ka 1080R / C65%, 1080HR / C 68%, 106R / C 73%, 106HR / C76%; Leha ho le joalo, moralo oa maqephe a 106 a phekotsoeng ka sekahare a nang le sekhomaretsi se phahameng a lokela ho qojoa ka hohle kamoo ho ka khonehang ho thibela ho kopana ha maqephe a mangata a sa phekolehang a 106. Hobane khoele ea khalase ea fiber e tšesaane haholo, ho putlama ha khoele ea khalase ea fiber sebakeng se seholo sa substrate ho tla ama botsitso ba tlhakore le lamination ea poleiti ea ho phatloha.

(4) Haeba moreki a sena litlhoko tse ikhethang, mamello ea botenya ba sebapali se kenang hangata e laoloa ke +/- 10%. Bakeng sa poleiti ea impedance, mamello ea botenya ba seaplane e laoloa ke mamello ea IPC-4101 C / M. Haeba tšusumetso ea impedance e amana le botenya ba substrate, mamello ea poleiti e tlameha ho laoloa ke mamello ea IPC-4101 C / M.

2.3 Taolo ea peakanyo ea libapali

Ho nepahala ha matšeliso a boholo ba phanele ea kahare le taolo ea boholo ba tlhahiso e lokela ho ipapisa le tlhaiso-leseling e fumanehang ho tlhahiso le nako ea nako e itseng ho lefella boholo ba lits’oants’o tsa karolo e ngoe le e ngoe ea karolo e kaholimo ho netefatsa botsitso ba katoloso le khutsufatso ea lera ka leng la karolo ea mantlha. Khetha maemo a holimo a ho nepahala le ho ts’epahala ho feta pele o tobetsa, joalo ka maemo a mane a li-slot (Pin LAM), ho qhibiliha ho chesang le ho kopanya rivet. Senotlolo sa ho netefatsa boleng ba ho tobetsa ke ho theha tšebetso e nepahetseng ea ho tobetsa le tlhokomelo ea letsatsi le letsatsi ea khatiso, ho laola sekhomaretsi se hatellang le phello ea ho futhumatsa, le ho fokotsa bothata ba karohano lipakeng tsa likarolo. Taolo ea peakanyo ea li-interlayer e hloka ho tsotelloa ka botlalo ho tloha boleng ba ka hare ba matšeliso, mokhoa o tobileng oa boemo, ho tobetsa mehato ea ts’ebetso, thepa ea thepa le lintlha tse ling.

Tsamaiso ea mola oa kahare

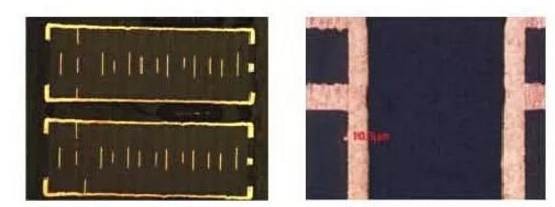

Hobane matla a ho sekaseka a mochini o pepesang oa setso o ka ba 50μm, bakeng sa tlhahiso ea boto ea boemo bo holimo, laser imager e tobileng (LDI) e ka hlahisoa ho ntlafatsa bokhoni ba lits’oants’o, bohlahlobi bo ka bang 20μm. Ho nepahala ha tokiso ea mochini o pepesang oa moetlo ke ± 25μm, mme ho nepahala ha tatellano ea li-interlayer ho feta 50μm. Ho nepahala ha boemo ba graph ho ka ntlafatsoa ho ba hoo e ka bang 15μm mme ho nepahala ha boemo ba sebapali ho ka laoloa kahare ho 30μm ka ho sebelisa mochini o hlakileng oa boemo bo phahameng, o fokotsang ho kheloha ha maemo a lisebelisoa tsa setso le ho ntlafatsa ho nepahala ha boemo ba sebapali sa bophahamo bo phahameng boto.

Bakeng sa ho ntlafatsa bokhoni ba ho ts’oara line, ho hlokahala hore o fane ka matšeliso a nepahetseng ho bophara ba mola le pad (kapa lesale la ho tjheseletsa) ho moralo oa boenjiniere, empa hape o hloka ho etsa lintlha tse qaqileng haholoanyane mabapi le moralo oa tefo ea lits’oants’o, joalo ka potoloho ea lupu, potoloho e ikemetseng joalo-joalo. Netefatsa hore na matšeliso a moralo oa bophara ba mola o kahare, sebaka sa mohala, boholo ba lesale la ho itšehla thajana, mohala o ikemetseng, hole-to-line hole hoa utloahala, kapa u fetole moralo oa boenjiniere. Moralo oa impedance le reaction reaction e hloka ho tsotelloa hore na moralo oa matšeliso oa mohala o ikemetseng le mohala oa impedance o lekane. Mekhahlelo e laoloa hantle ha ho etsoa manonyeletso, ‘me sengoathoana sa pele se ka hlahisoa ka bongata kamora ho netefatsoa e le se tšoanelehang. Bakeng sa ho fokotsa khoholeho ea lehlakore la mananose, ho hlokahala hore ho laoloe sebopeho sa tharollo ea etch maemong a matle. Thepa ea setso ea mananose e na le bokhoni bo sa lekanang, ka hona lisebelisoa li ka fetoloa kapa tsa kenngoa kahare ho lisebelisoa tse phahameng tsa ho betla line ho ntlafatsa ho tšoana, ho fokotsa litšila le manonyeletso a mang.

2.5 Ts’ebetso ea ho tobetsa

Hajoale, mekhoa ea ho beha li-interlayer pele e tobetsa haholo e kenyelletsa: li-slot tse nne (Pin LAM), qhibiliha e chesang, rivet, melt e chesang le motsoako oa rivet. Mefuta e fapaneng ea lihlahisoa e amohela mekhoa e fapaneng ea ho beha maemo. Bakeng sa lipoleiti tse phahameng, maemo a mane a li-slot (Pin LAM), kapa fusion + riveting, OPE e phunya masoba a boemo ka nepahalo a laoloang ho ± 25μm. Nakong ea tlhahiso ea methapo, ho hlokahala hore ho hlahlojoe hore na poleiti ka ‘ngoe e kentsoe ka har’a yuniti ho thibela stratification e latelang. Lisebelisoa tse hatellang li sebelisa mochini o tšehetsang ts’ebetso e phahameng ho fihlela ho nepahala ha lipapatso tsa lipapaling le ts’epahalo ea poleiti e phahameng.

Ho ea ka sethala se holimo se laminated le lisebelisoa tse sebelisitsoeng, lits’ebetso tse nepahetseng tsa ho tobetsa, li beha sekhahla se futhumatsang le sekhahla ka ho fetesisa, ho mekgwa e tloahelehileng ea li-multilayer PCB, e loketseng ho fokotsa sekhahla sa ho futhumatsa sa tšepe, ho eketsa nako ea ho futhumatsa mocheso o phahameng, ho etsa lehoakhoa phallo, phekola, ka nako e tšoanang qoba skateboard ka tshebetso ya ho tobetsa, bothata interlayer displacement. Boitsebiso ba boleng ba TG ha se boto e le ‘ngoe, e ke ke ea ba boto e ts’oanang ea grate; Mekgwa e tloaelehileng ea boto e ke ke ea tsoakana le mekhahlelo e ikhethileng ea boto; Ho etsa bonnete ba hore sekhahla sa katoloso le khutsufatso se sebetsa hantle, ts’ebetso ea lipoleiti tse fapaneng le maqephe a phekotsoeng ha a fapane, mme mekhahlelo e lekanang ea lisepa tse phekotsoeng e lokela ho sebelisoa ho tobetsa, ‘me lisebelisoa tse khethehileng tse e-so ka li sebelisoa li hloka ho netefatsa mekhahlelo ea ts’ebetso.

2.6 Ts’ebetso ea ho cheka

Ka lebaka la superposition ea mong le e mong lera, poleiti le lera koporo li bartolomeo teteaneng, e leng se etsa hore qhoaele tebileng ka tirila batla ‘me ho bonolo ho roba sesebelisoa tirila. Palo ea masoba, lebelo le oang le lebelo le potolohang e lokela ho theoloa ka nepo. Lekanya ka nepo katoloso le khutsufatso ea poleiti, ho fana ka coefficient e nepahetseng; Palo ea dikarolo ≥14, lesoba bophara ≤0.2mm kapa lesoba ho mola hole ≤0.175mm, ts’ebeliso ea ho nepahala ha lesoba production0.025mm tlhahiso ea ho cheka; Mohato cheka e sebediswa bakeng sa bophara φ4.0mm kapa ka holimo, mohato cheka e sebediswa bakeng sa botenya ho bophara karo-karolelano 12: 1, ‘me cheka e ntle le e mpe e sebediswa bakeng sa tlhahiso. Laola ho cheka ka pele le bophara ba lesoba. Leka ho sebelisa thipa e ncha kapa ho sila thipa e le ‘ngoe ho cheka boto e kaholimo. Bophara ba lesoba bo lokela ho laoloa kahare ho 1um. Bakeng sa ho rarolla bothata ba burr ea ho cheka lesoba la poleiti e teteaneng ea koporo boemong bo phahameng, ho netefalitsoe ka teko ea methapo hore ho sebelisa sethala se phahameng sa palo, palo ea poleiti e le ngoe mme ho cheka hanyane nako ea ho sila e laoloa nakong ea makhetlo a 25 ho ka ntlafatsa burr ea lesoba la ho cheka

Bakeng sa maqhubu a phahameng, lebelo le lebelo la phetiso ea data ea boto e phahameng, theknoloji ea ho cheka morao ke tsela e atlehang ea ho ntlafatsa bots’epehi ba matšoao. Sebaka sa ho cheka ka morao se laola bolelele ba sethala se setseng, ho tsitsisa ha sebaka sa lesoba lipakeng tsa masoba a mabeli a ho cheka le terata ea koporo ka sekoting. Ha se lisebelisoa tsohle tsa ho ikoetlisa tse nang le ts’ebetso ea ho cheka morao, hoa hlokahala ho etsa ntlafatso ea tekheniki ea lisebelisoa tsa ho cheka (ka ts’ebetso ea ho cheka ka morao), kapa ho reka driller e nang le ts’ebetso ea ho cheka ka morao. Mekhoa ea ho cheka ka morao e sebelisitsoeng ho lingoliloeng tse amanang le indasteri le tlhahiso ea bongata bo holileng e kenyelletsa haholo-holo mokhoa oa ho cheka botebo ba moetlo, ho cheka ka morao ka mokato oa lipontšo lera la kahare, lipalo tsa botebo ba ho cheka morao ho latela karolelano ea botenya ba poleiti, e ke keng ea phetoa mona.

Tse tharo, teko ea ts’epahalo

The boto ea boemo bo holimo ka kakaretso ke boto ea sistimi, e motenya ho feta boto e tloaelehileng ea li-multilayer, e boima, boholo ba yuniti, mocheso o lekanang oa mocheso le ona o moholo, ho tjheseletsa, tlhoko ea mocheso o mong, nako ea mocheso o phahameng oa mocheso o telele. Ho nka metsotsoana e 50 ho isa ho e 90 ho 217 ℃ (ntlha e qhibilihisang ea tšepe ea tšepe-ea koporo), ‘me lebelo le pholileng la poleiti e phahameng le batla le lieha, kahoo nako ea teko ea ho tjheseletsa hape e atolosoa. Hammoho le ipC-6012C, IPC-TM-650 litekanyetso le litlhoko tsa indasteri, teko e kholo ea ts’epahalo ea poleiti e phahameng e hlalositsoe ho Tafole ea 2.

Table2