- 04

- Oct

Inkqubo yolawulo lwemveliso ephambili yebhodi yesekethe ephezulu

Inqanaba eliphezulu PCB Ichazwa ngokubanzi njengamaleko ali-10 – maleko angama-20 okanye ngaphezulu kwe- ibhodi yesekethe ephezulu. Kunzima ngakumbi ukuqhubekeka kunebhodi yesekethe eyahlukeneyo yemveli, kwaye iimfuno zayo zomgangatho kunye nokuthembeka ziphezulu. Isetyenziswa ikakhulu kwizixhobo zonxibelelwano, iiseva zokugqibela, izixhobo zombane zonyango, ukuhamba ngenqwelomoya, ukulawulwa kwemizi-mveliso, ezomkhosi kunye nezinye iinkalo. Kwiminyaka yakutshanje, imfuno yentengiso ephezulu yebhodi kunxibelelwano olusetyenzisiweyo, isikhululo sesiseko, ukuhamba ngenqwelomoya, ezomkhosi kunye nezinye iindawo zomelele, kwaye ngophuhliso olukhawulezileyo lwentengiso yezixhobo zonxibelelwano zaseTshayina, ithemba lentengiso yebhodi ephezulu iyathembisa .

Okwangoku, ukuveliswa kwemilinganiselo emikhulu yabenzi be-PCB ekumgangatho ophezulu e-China ikakhulu kuvela kumashishini axhaswa ngemali aphesheya okanye inani elincinci lamashishini asekhaya. Imveliso yebhodi yesekethe ekumgangatho ophezulu ayifuni kuphela itekhnoloji ephezulu kunye nezixhobo zotyalo-mali, kodwa ikwafuna ukuqokelelwa kwamava abasebenzi bezobuchwephesha kunye nabasebenzi bemveliso. Kwangelo xesha, ukungeniswa kweenkqubo zokuqinisekiswa kwabathengi kwibhodi ephezulu kungqongqo kwaye kunzima, ke ibhodi yesekethe ekumgangatho ophezulu ingena kwishishini ngomda ophakamileyo, kwaye umjikelo wokuveliswa kwemizi mveliso mde. Inani eliphakathi lemiqolo ye-PCB iye yaba sisalathiso sobuchwephesha esibalulekileyo sokulinganisa inqanaba lobuchwephesha kunye nemveliso yeshishini le-PCB. Eli phepha lichaza ngokufutshane ubunzima bokusebenza obuphambili kwimveliso yebhodi yesekethe ekumgangatho ophezulu, kwaye yazisa ngamanqaku aphambili olawulo lwenkqubo yemveliso ephambili yebhodi yesekethe ekumgangatho ophezulu wesalathiso sakho.

Inye, eyona ngxaki inkulu yemveliso

Xa kuthelekiswa neempawu zeemveliso zebhodi yesekethe yesiqhelo, ibhodi yesekethe ekumgangatho ophezulu ineempawu zecandelo lebhodi ejiyileyo, umaleko ongaphezulu, imigca eshinyeneyo kunye nemingxunya, ubungakanani beyunithi enkulu, umaleko obhityileyo ophakathi, njl., Kunye nendawo yangaphakathi, phakathi ulungelelwaniso -layer, ulawulo impedance kunye neemfuno ukuthembeka zingqongqo ngakumbi.

1.1 Ubunzima bokulungelelaniswa kwabadlali abaninzi

Ngenxa yenani elikhulu leebhodi eziphezulu zokunyuka, ukuphela koyilo lomthengi kuneemfuno ezingaphezulu nangqongqo kulungelelwaniso lwee-PCB. Ngokwesiqhelo, ulungelelwaniso lokunyamezelana phakathi kwamanqanaba alawulwa ukuba abe yi-± 75μm. Ukujonga ubungakanani obukhulu bokuyilwa kwebhodi ephezulu, ubushushu obugcweleyo kunye nokufuma kweworkshop yokudlulisa imifanekiso, kunye nokususwa okungafunekiyo okubangelwe kukungangqinelani kolwandiso kunye nokuncipha kobume beebhodi ezahlukeneyo, imeko yokuma phakathi konwebu kunye nezinye izinto, It yenza kube nzima ngakumbi ukulawula ulungelelwaniso phakathi kwamanqanaba ebhodi ephezulu.

1.2 Ubunzima ekwenzeni isekethe yangaphakathi

Ibhodi ephezulu yokuphakama yamkela izinto ezizodwa ezinje nge-TG ephezulu, isantya esiphezulu, amaza aphakamileyo, ubhedu obungqindilili, umaleko ophakathi ophakathi, njl. Ukuhanjiswa komqondiso, okwonyusa ubunzima bokungunda kwesekethe yangaphakathi. Umgca wobubanzi bomgca omncinci mncinci, vula ukwanda kwesekethe emfutshane, ukwanda okufutshane okuncinci, izinga lokupasa eliphantsi; Kukho umaleko womqondiso omninzi kumgca oxineneyo, kunye nokubakho kokungabikho kwe-AOI kulwakhiwo lwangaphakathi luyanda. Ubunzima beplate yangaphakathi engqindilili icekeceke, kulula ukuyisonga ekhokelela ekuvezeni okungalunganga, kulula ukuyisonga ipleyiti xa usotya; Uninzi lweebhodi eziphakamileyo eziphakamileyo ziibhodi zenkqubo, kwaye ubungakanani beyunithi bukhulu, ke ixabiso lezixhobo ezilahliweyo ziphezulu kakhulu.

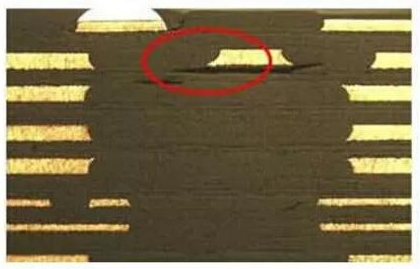

1.3 Ubunzima bemveliso yokucinezela

Amacwecwe amaninzi angaphakathi angaphakathi kunye neepleyiti eziphilisiweyo zenziwe zangaphezulu, kwaye iziphene ezinje ngesilayidi, i-lamination, i-resin cavity kunye ne-bubble residue ziveliswa ngokulula ngexesha lokucinezela imveliso. Kuyilo lolwakhiwo laminethi, kubalulekile ukuba uqwalasele ngokupheleleyo ubushushu bemathiriyeli, ukumelana kwamandla ombane, isixa seglue kunye nobungqindilili obuphakathi, kwaye usete inkqubo yokucinezela ipleyiti efanelekileyo. Ngenxa yenani elikhulu lamanqanaba, ukwanda kunye nolawulo lwe-shrinkage kunye nobukhulu bembuyekezo eyoneleyo ayinakugcina ukungaguquguquki; Umaleko omncinci wokugquma phakathi kwamanqanaba ngokulula ukhokelela ekusileleni kovavanyo lokuthembeka phakathi kwamanqanaba. Umzobo 1 ngumzobo wesiphene wokuqhekeka kwepleyiti emva kovavanyo loxinzelelo lwethempile.

1.4 Iindawo ezinzima ekubholeni

Amacwecwe obhedu akhethekileyo ane-TG ephezulu, isantya esiphezulu, amaza aphakamileyo kunye nobukhulu obukhulu basetyenziselwa ukwandisa ubunzima bokugrumba uburhabaxa, i-burr kunye ne-decontaminate. Inani lemiqolo, ubukhulu ubhedu lilonke kunye ipleyiti ukutyeba, kulula ukwaphula kusombiwa imela; Ukungaphumeleli kweCAF kubangelwe yi-BGA eshinyeneyo kunye nemingxunya emingxunya eludongeni; Ubunzima beplate bunokukhokelela ngokulula kwingxaki yokomba i-skew.

Ii. Ukulawulwa kweenkqubo eziphambili zemveliso

2.1 Ukhetho lwezixhobo

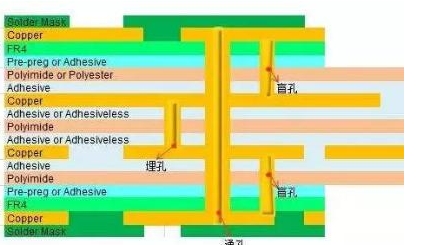

Ngokwenza ukusebenza okuphezulu kwezinto ze-elektroniki, ezisebenza ngakumbi kwicala lophuhliso, ngaxeshanye ngesantya esiphakamileyo, ukukhula ngesantya esiphezulu sokuhambisa umqondiso, ke izinto zesekethe zombane zedizili rhoqo kunye nelahleko ye-dielectric iphantsi, kwaye i-CTE esezantsi, amanzi asezantsi Ukufunxwa kunye nokusebenza okuphezulu kwezinto ezilungiselelwe ubhedu, ukwanelisa imfuno yokuqhutywa kweplate ephezulu kunye nokuthembeka. Abathengisi beplate abaqhele ukusetyenziswa ikakhulu kubandakanya uthotho, uthotho B, uthotho lwe-C kunye no-D uthotho. Jonga iitheyibhile 1 ngokuthelekisa ezona mpawu ziphambili zezi zine zangaphakathi. Ukuqina okuphezulu kwesiqingatha sebhodi yesekethe yokukhetha umxholo we-resin ephezulu, isiqingatha se-interlayer sokuqiniswa kwentlaka yanele kwimizobo yokugcwalisa, umaleko we-dielectric urhabaxa kulula kakhulu ukuba ubonakale ngathi yipleyiti egqityiweyo, ngelixa i-slants ibhityile, umaleko we-dielectric kulula ukukhokelela kulwazelelo oluphakathi, ukusilela kovavanyo oluphezulu njengengxaki esemgangathweni, ke ukhetho lwezixhobo zedielectric lubaluleke kakhulu.

2.2 Uyilo lolwakhiwo olunamanzi

Kuyilo lolwakhiwo laminethi, ezona zinto ziphambili ekufuneka ziqwalaselwe kukuchasana nobushushu bezinto, uxhathiso lwevolthi, isixa seglue kunye nobungqingqwa besingqimba esiphakathi, njl.

(1) Isiqwenga esiphilisiweyo kunye nomvelisi weplate oyintloko kufuneka zingqinelane. Ukuqinisekisa ukuthembeka kwe-PCB, onke amacwecwe eepilisi eziphilisiweyo kufuneka akuphephe ukusebenzisa iitafile ze-1080 okanye ze-106 ezinyangiweyo (ngaphandle kweemfuno ezizodwa zabathengi). Xa kungekho mfuneko yobukhulu obuphakathi, ubukhulu bephakathi phakathi kwamanqanaba kufuneka ibe ngu -0.09mm ngokwe-IPC-A-600g.

(2) Xa umthengi efuna ipleyiti ephezulu ye-TG, isitya esiphambili kunye nepleyiti ephilisiweyo kufuneka isebenzise izinto eziphezulu zeTG.

(3) I-substrate yangaphakathi ye-3OZ okanye ngaphezulu, khetha umxholo we-resin ophezulu wamacwecwe aphilisiweyo, anjenge-1080R / C65%, 1080HR / C 68%, 106R / C 73%, 106HR / C76%; Nangona kunjalo, uyilo lolwakhiwo lwee-sheet ezili-106 eziphilisiweyo ezinamathelisi aphezulu kufuneka zithintelwe kangangoko kunokwenzeka ukuthintela ukugqagqana kwamaphepha ali-106 aphilileyo. Ngenxa yokuba umsonto wefayibha yeglasi ubhityile kakhulu, ukuwa kwentambo yeglasi yefayibha kwindawo enkulu esecaleni kuya kuchaphazela uzinzo lobungakanani kunye nokukhutshwa kwepleyiti yokuqhushumba.

(4) Ukuba umthengi akanazo iimfuno ezizodwa, ubukhulu bokunyamezelana kwendlela ephakathi kulawulwa ngokubanzi +/- 10%. Kwisitya se-impedance, ukunyamezelana kobukhulu kulawulwa yi-IPC-4101 C / M ukunyamezelana. Ukuba impedance ifuthe kwinto inxulumene nobukhulu be-substrate, unyamezelo lweplate kufuneka lulawulwe kukunyamezelana kwe-IPC-4101 C / M.

2.3 Ulawulo lokuhambelana kolungelelwaniso

Ukuchaneka kwembuyekezo yangaphakathi yeplanethi yolawulo kunye nolawulo lwesayizi yemveliso kufuneka kusekwe kwidatha nakwidatha yembali eqokelelwe kwimveliso ngexesha elithile lokuhlawulela ngokuchanekileyo ubungakanani begraphic yomaleko ngamnye wepaneli ephezulu yokuqinisekisa ukungqinelana ukwandiswa kunye nokuncipha kwoluhlu ngalunye lwephaneli engundoqo. Khetha ukuchaneka okuphezulu kunye nokuma okuthembekileyo kokumiswa ngaphambi kokucinezela, njengokubeka indawo ezine (i-Pin LAM), ukunyibilika okushushu kunye nokudityaniswa kwe-rivet. Isitshixo sokuqinisekisa umgangatho wokucinezela kukuseta inkqubo efanelekileyo yokucinezela kunye nokugcinwa kwemihla ngemihla komatshini wokushicilela, ukulawula iglu yokucinezela kunye nokupholisa ukusebenza, kunye nokunciphisa ingxaki yokusasazeka phakathi kweendlela. Ulawulo lokuhambelana kolungelelwaniso kufuneka luqwalaselwe ngokubanzi ukusuka kwixabiso lembuyekezo yangaphakathi, imo yokucinezela, inkqubo yokucinezela iiparameter, iipropathi zezinto kunye nezinye izinto.

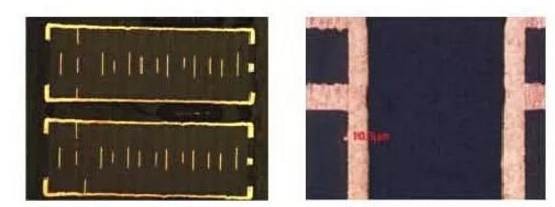

2.4 Inkqubo yomgca ongaphakathi

Kuba amandla ohlalutyo lomatshini wokubhengeza ngokwesiko umalunga ne-50μm, kwimveliso yebhodi ekumgangatho ophezulu, umfanekiso we-laser ngqo (LDI) unokwaziswa ukuphucula amandla ohlalutyo lwegraphic, amandla ohlalutyo malunga ne-20μm. Ukuchaneka kokulungelelaniswa komatshini wokubhenca ngokwesiko ngu- ± 25μm, kwaye ulungelelwaniso lokulungelelanisa phakathi kwabadlali bukhulu kune-50μm. Ukuchaneka kokubeka igrafu kungaphuculwa ukuya kuthi ga kwi-15μm kunye nokuchaneka kokuma kwindawo yokuma kungalawulwa ngaphakathi kwe-30μm ngokusebenzisa umatshini wokubekwa kwindawo ephezulu, okunciphisa ukubekwa ecaleni kwezixhobo zemveli kunye nokuphucula ukubekwa ngokuchanekileyo kokuma okuphezulu Ibhodi.

Ukuze kuphuculwe amandla okutsalwa komgca, kuya kufuneka unike imbuyekezo efanelekileyo kububanzi bomgca kunye nephedi (okanye iringi yokuwelda) kuyilo lobunjineli, kodwa kufuneka ukwenze ngakumbi ukuqwalasela uyilo oluneenkcukacha kwimali yembuyekezo ekhethekileyo iigrafiki, ezinje ngesekethe yokujikeleza, isekethe ezimeleyo njalo njalo. Qinisekisa ukuba ngaba imbuyekezo yoyilo kububanzi bomgca wangaphakathi, umgama womgca, ubungakanani bendandatho yokuzahlula, umgca ozimeleyo, umngxunya-kumgca wokulinganisa unengqiqo, okanye utshintshe uyilo lobunjineli. Uyilo lwe-impedance kunye nokusabela okungafunekiyo kufuna ingqalelo yokuba uyilo lwembuyekezo yomgca ozimeleyo kunye nomgca we-impedance wonele. Iiparamitha zilawulwa kakuhle xa kudityaniswa, kwaye isiqwenga sokuqala sinokuveliswa ngobuninzi emva kokuqinisekiswa njengefanelekileyo. Ukwenzela ukunciphisa ukhukuliseko lomhlaba osecaleni, kufuneka ulawule ukwenziwa kwesisombululo se-etch kuluhlu olulungileyo. Isixhobo esine-line esixhonyiweyo asinabuchule obaneleyo bokutsala, ngoko ke izixhobo zinokutshintshwa ngobuchwephesha okanye zingeniswe kwizixhobo zemigca yokutsala ephezulu-ngakumbi ukuphucula ukufana kokutsalwa, ukunciphisa i-burr etching, ukungcola okungafaniyo nezinye iingxaki.

2.5 Inkqubo yokucinezela

Okwangoku, iindlela zokubeka phakathi kwabadlali ngaphambi kokucinezela ikakhulu zibandakanya: ukubekwa kwindawo ezine (i-Pin LAM), ukunyibilika okushushu, i-rivet, ukunyibilika okushushu kunye nokudityaniswa kwe-rivet. Izakhiwo ezahlukeneyo zeemveliso zamkela iindlela zokubeka ezahlukeneyo. Kwiipleyiti zenqanaba eliphezulu, ukubekwa kwindawo ezine (i-Pin LAM), okanye i-fusion + i-riveting, i-OPE ibetha imingxunya yokuma ngokuchanekileyo elawulwa kwi-± 25μm. Ngexesha lokuveliswa kwebhetshi, kufuneka ujonge ukuba ngaba ipleyiti nganye idityanisiwe na kwiyunithi ukunqanda ukubekwa esitalatweni okulandelayo. Isixhobo ngokucinezela yamkela-yokusebenza eliphezulu ukuxhasa cofa ukuhlangabezana ukuchaneka ulungelelwaniso labadlali kunye nokuthembeka ipleyiti eliphezulu-enyukayo.

Ngokweplathi ephezulu elaminethiweyo kunye nezinto ezisetyenzisiweyo, iinkqubo ezifanelekileyo zokucinezela, ukuseta elona zinga liphezulu lokufudumeza kunye negophe, kwiinkqubo zokucinezela ze-multilayer ze-PCB ezifanelekileyo, ezifanelekileyo ukunciphisa ireyithi yokucinezela yokufudumeza isinyithi, ukwandisa ixesha lokunyanga ubushushu obuphezulu, yenza ukuhamba kwentlaka, ukunyanga, kwangaxeshanye kuthintele i-skateboard kwinkqubo yokucinezela, ingxaki yokufuduka yabadlali. Ixabiso lexabiso le-TG ayibhodi enye, ayinakuba yibhodi enye ye-grate; Iiparamitha eziqhelekileyo zebhodi azinakuxutywa kunye neeparamitha zebhodi; Ukuqinisekisa ukwandiswa kokuthotyelwa kunye nokunciphisa ukungalingani, ukusebenza kwamacwecwe ahlukeneyo kunye namashiti anyangiweyo ahlukile, kwaye iiparameter zephepha eliphilisiweyo kufuneka zisetyenziselwe ukucofa, kwaye izixhobo ezizodwa ezingasetyenziswanga kufuneka ziqinisekise Inkqubo yeparamitha.

2.6 Inkqubo yokomba

Ngenxa yokubekwa kwindawo ephezulu yoluhlu ngalunye, ipleyiti kunye nocingo lobhedu zityebile kakhulu, ezibangela ukunxiba okungathandekiyo kwisuntsu lokumba kwaye kulula ukwaphula isixhobo sokumba. Inani lemingxunya, isantya esiwayo kunye nesantya esijikelezayo kufuneka sehliswe ngokufanelekileyo. Ukulinganisa ngokuchanekileyo ukwanda kunye nokuncipha kwesitya, ukubonelela ngokulingana okuchanekileyo; Inani lamanqanaba ≥14, umngxuma ≤0.2mm okanye umngxuma kumgama womgama ≤0.175mm, ukusetyenziswa kokuchaneka komngxunya production0.025mm kwimveliso yokugrumba; Inyathelo lokomba lisetyenziselwa ubukhulu φ4.0mm okanye ngaphezulu, inyathelo lokomba lisetyenziselwa ukutyeba ukuya kububanzi be-12: 1, kwaye kusetyenziselwa ukubhola okuhle nokubi. Lawula ukubhola ngaphambili kunye nobubanzi bemingxunya. Zama ukusebenzisa imela entsha yokugrumba okanye usile imela yokugrumba e-1 ukubhola ibhodi ephezulu. Ububanzi bomngxuma kufuneka bulawulwe ngaphakathi kwe-25um. Ukuze kusonjululwe ingxaki ye-burr yokugrumba umngxuma weplate eshinyeneyo kwinqanaba eliphezulu, kungqinwa kuvavanyo lwebhetshi ukuba kusetyenziswa iphedi yokuxinana okuphezulu, inani leplate yokufaka yenye kwaye ukubhola ixesha lokugaya kulawulwa ngaphakathi kwamaxesha ama-3 kunokuyiphucula ngokufanelekileyo i-burr umngxunya wokugrumba

Ukuhamba rhoqo, isantya esiphezulu kunye nokuhanjiswa kwedatha ngobuninzi bebhodi ephezulu, itekhnoloji yokubhola umva yindlela efanelekileyo yokuphucula ukuthembeka. Ukubhola ngasemva ikakhulu kulawula ubude be-stub eyintsalela, ukungqinelana kwendawo yemingxunya phakathi kwemingxunya emibini yokomba kunye nocingo lobhedu emngxunyeni. Ayizizo zonke izixhobo zokuqhuba ezinomsebenzi wokugrumba umva, kubalulekile ukwenza uhlaziyo lobuchwephesha bezixhobo zokuqhuba (ngomsebenzi wokubuyela umva), okanye ukuthenga isixhobo sokuqhuba ngomsebenzi wokugrumba ngasemva. Iindlela zokugrumba ngasemva ezisetyenzisiweyo kushishino loncwadi olufanelekileyo kunye nemveliso yobuninzi obuvuthiweyo ikakhulu zibandakanya: indlela yokuthambisa ubunzulu bendabuko ukubuyela umva kwendlela, ukubhola ngasemva ngombono wempendulo kumaleko wangaphakathi, ukubalwa kobunzulu bokubuyela umva ngokungqinelana nomlinganiso wobunzima beplate, obungayi phindwa apha.

Isithathu, uvavanyo lokuthembeka

The ibhodi ekwinqanaba eliphezulu Ngokubanzi yibhodi yenkqubo, iyatyeba ngaphezu kwebhodi yesiqhelo ye-multilayer, inzima, ubukhulu beyunithi enkulu, amandla obushushu ahambelanayo nawo makhulu, kwi-welding, isidingo sobushushu obungaphezulu, ixesha lokushisa eliphezulu le-welding lide. Ithatha imizuzwana engama-50 ukuya kuma-90 ukuya kuma-217 ℃ (indawo yokunyibilikisa ityhidi-yesilivere-ityhidiweyo), kwaye isantya sokupholisa isitya esiphakamileyo siyacotha, kungoko ixesha lokuvavanywa kokufakwa kwewelding liyandiswa. Ngokudityaniswa ne-ipC-6012C, imigangatho ye-IPC-TM-650 kunye neemfuno zeshishini, olona vavanyo luthembekileyo lwetafile ephezulu ichazwe kwiTheyibhile 2.

Itheyibhile2